All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(928 products available)

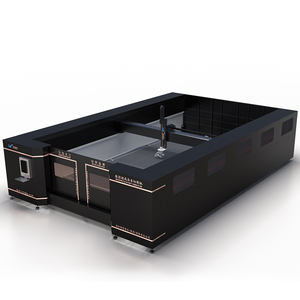

The Yongda water jet machine has several different versions to cater to the various needs of workflow around the globe. Machines are intentionally designed to cut metal and glass sheets or parts of different materials.

These machines can also be used to carve or engrave patterns and artistic reliefs onto metals or stone. In this and the following sections, the precise differences in these machines will become clear.

Therefore, below are the various types of Yongda water jet machines:

This machine uses Ultrahigh stream pressure jet streams. The pressure can be up to 5500 kg per square centimeter. Such high pressure is capable of cutting even materials as tough as titanium and granite with great precision. Common industries that use this machine are aerospace and automotive in which they need cutting of tough metals and complex shapes.

This cutter is meant specifically for cutting materials that are difficult to machine without cutting fluids, such as water-soluble synthetics and other chemicals. However, it does not have an integrated pump. Instead, it uses an external pump to save space. The fact that it is compact makes it ideal for small businesses or workshops.

This machine is meant to cut hard materials like metals and stones. Instead of pure water, the stream also contains an abrasive material such as garnet. The stream is mixed in an abrasive nozzle. It increases the cutting power of the stream significantly. This machine is well-suited for cutting thick materials that are over 6 mm in thickness.

As the name suggests, this water jet cutter only uses water to cut soft materials like plastics, wood, and thin sheets of metal. It does not require any additives or abrasives. It is commonly used to cut materials up to a few millimeters thick. Because it is small and portable, it is suitable for homebased entrepreneurs or small industries.

The 5-axis cutter is meant for cutting complex three-dimensional shapes. Thanks to the additional two axes of movement, the cutter can tilt and rotate to make angled cuts. Such versatility is perfect for industries such as automotive or aerospace where parts need more integrated design.

The Yongda water jet machine is widely used in the metalworking industry to cut sheet metals and steel plates into various shapes and sizes. Unlike traditional cutting tools, water jet cutting does not generate heat, which prevents the edges of the metal from warping or altering from their original properties.

This feature is especially crucial when cutting materials that have been hardened or treated for structural reinforcement. Water jet cutting also accommodates cutting metals with patterns or designs that would otherwise be difficult to achieve.

There’s a lot of precision cutting involved in the making of components in the aerospace industry. Examples of components include wings, fuselages, and engines, to name a few. Water jet machines are best placed to accomplish this task as they can cut tough materials like titanium and composites whilst maintaining high dimensional accuracy.

Apart from cutting, water jets are used to engrave intricate designs, markings, or serial numbers onto aerospace components. Engraving after the cutting process would increase the complexity involved, so water jets do the engraving simultaneously as they do the cutting.

Water jets have become popular for jewellery designers because they can create detailed and intricate designs. Precious metals such as gold, silver, and platinum hard to cut using normal cutters are easily cut with water jets.

The precision cutting capability also allows designers to create very fine patterns or shapes that will then make unique pieces in demand in the jewellery market. There’s another benefit that comes with cutting using water jets. These jets reduce the mechanical stress that handling these metals inflicts on them, and as mentioned earlier, they don’t cause heat damage.

Automotive is another industry that uses Yongda water jet machines to cut, etch, and engrave different materials or parts. The materials could be metals, glass, gaskets, or even composite materials such as carbon fiber. The key cuts are usually those made on the engine parts, body frames, and other complicated components.

What’s more, water jets are capable of cutting automotive glass to required specifications for use as side or rear windows on vehicles. They define the cut without leaving rough edges or causing cracks.

Water jets are very useful in cutting brittle materials that would crack or break under direct mechanical cutting. In the stone industry, water jets are used to cut granite, marble, and other types of natural stones into slabs or tiles for countertops, flooring, and other installations.

What these water jets do is provide precision in cutting stones that have intricate designs or patterns for artistic purposes. In the ceramics industry, water jets cut or engrave tiles for flooring or decorative purposes or make precise cuts on ceramic materials for artistic and functional applications.

In addition, proper waste disposal should be done because cutting with abrasives generates a lot of abrasive waste that might be contaminated with hazardous materials. It is prudent to manage this waste properly and dispose of it according to local regulations.

A1. Yongda Water jets use several cutting methods to accommodate different cutting needs. Pure water jet cutting involves using solely water without any additives to cut soft materials like plastics, wood, and thin metal sheets. This method is ideal for providing a clean cut without rough edges or heat damage.

For harder materials such as metals, stone, or glass, abrasive water jet cutting is employed. This technique incorporates an abrasive substance mixed with water to intensify the cutting power. It’s particularly useful for thick or hard materials that require more energy to achieve precise cuts. Finally, when cutting materials with water-soluble needs, such as chemicals or plastics, water-soluble jet cutting is used.

A2. The type of water jet machine to operate depends on the material that needs to be cut. For soft materials such as plastics, wood, and thin metals, a pure water jet cutter is sufficient. There’s no need for abrasive additives to cut these simple materials.

However, for tougher materials like thick metals or stones, an abrasive water jet cutter is the most effective. Though these machines are larger and more complex, they are the only ones capable of producing quality cuts on hard materials.

The other consideration is size: small-scale jobs requiring low power can use a 5-axis water jet or a water-soluble jet machine. These machines have relatively fewer cutting spaces because of their workspace length and are easy to use at home. For larger jobs that require morework space length and complicated cuts, try a pure water jet machine or an abrasive water jet machine with more cutting heads.

A3. Water jets do not generate heat. They are capable of cutting materials without causing the material’s interior to become distorted due to heat. This property is especially useful when cutting laminated composites or metals that have undergone heat treatment.

On the other hand, Plasma cutters and laser cutters generate significant heat. It might cause warping and discoloration on the edges of the cuts. Therefore, water jets are ideal for cutting materials that are sensitive to heat, while plasma cutting and laser cutting are better suited for materials that can withstand high temperatures.

A4. Use personal protective equipment such as safety glasses, gloves, and ear protection. Water jets can produce high-speed jets of water that are dangerous. High-speed water jetting creates high-speed jetting that causes water-jet cutters to bind, and as a result, a part holder breaks or moves, and severe injuries are likely to occur.

Safety guards are positioned around the area of operation for a good reason— to protect the operators. Do not attempt to open or operate any machine that is enclosed by safety guards without first removing the guards. Of all the machines, water jet cutters are the most hazardous because they produce a jet stream that, under normal circumstances, is enclosed by water. However, without protective gear, the cutter has the potential to harm the cutters.

These machines comply with all local, international, and OSHA safety regulations. They are designed to perform all cutting operations safely. Manufacturers provide manuals where there are essential safety measures and advice on when and how to service or maintain the machine.