All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1110 products available)

The Yin auto cutter is an essential tool in garment manufacturing. With a growing desire for efficiency and cost-cutting in the industry, the need for automatic cutting machines has increased. The Yin auto cutter helps reduce fabric wastage, improve accuracy, and increase production speed, which are all critical components of successful garment manufacturing. Several types of Yin cutters suit various applications, piles of fabrics, and preferences.

Spindle Cutting Machine:

The spindle cutting machine is ideal for cutting large piles of fabric. It has spindles that hold the fabric in place as it is being cut. cutters can cut through three inches to ten inches of material. Yin spindle auto cutters have a camera system for easy mark identification. The camera scans the marks that need to be cut, reducing operator input and increasing cutting speed and accuracy. The cutter then follows the marks, making the required cuts.

Contour Cutting Machine:

The contour Yin auto cutter follows pre-programmed outlines or contours to cut fabrics into specific shapes. It is excellent for cutting logos or designs with intricate details. With its computer numerical control (CNC) system, the machine provides high precision and repeatability in cutting operations. It can cut through various types of fabric, including stretchy and slippery materials that are usually hard to cut.Manufacturers use it to create patterns and templates for fashion items. Some Yin contour auto cutters have layered scanning and slicing. This means that the machine can scan multiple layers of fabric at once, slice through them, and make accurate cuts according to the design without damaging the other layers.

Dragging Auto Cutter:

The dragging auto cutter is ideal for cutting single-layer to medium piles of fabric. It has a dragging mechanism that smoothly pulls the fabric through the machine as it is being cut. The design enables accurate cuts with minimal fabric distortion, saving material.

Cutting width and length

YiN auto cutters come with many cutting widths and cutting lengths to satisfy different fabric cutting needs and limits.

Cutting speed

YiN auto cutters have different cutting speeds. The speed can be constant or adjustable; also, it may vary depending on the specific model and settings.

Cutting accuracy

YiN auto cutters can provide accurate cutting results. Depending on the model, different precision can meet various manufacturing needs.

Power

YiN auto cutters' power is the driving force behind fabric cutting. Power is usually measured in watts (W) or horsepower (HP).

Control system

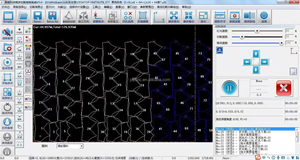

YiN auto cutters are Support Many control systems. For example, a touchscreen or computer software is used to control the cutter's cutting parameters, speed, and precision.

Cutting method

YiN auto cutters can use various cutting methods, such as laser cutting, knife cutting, or blade cutting, to meet different material and application requirements.

Maintenance is essential to ensure optimal cutting performance and prolong the lifespan of the machine. Here are some maintenance tips for maintaining an auto cutter machine:

Regular lubrication:

Auto cutters typically have moving components requiring regular lubrication. Lubricate the machine using the appropriate lubricant according to the manufacturer's instructions to reduce wear and ensure smooth operation.

Frequent cleaning:

Regularly clean the entire auto-cutting machine to remove fabric remnants, dust, and dirt. Use a soft cloth, brush, and suitable cleaning agents to keep the cutting area and surfaces free of contaminants and prevent clogging or affecting the cutting precision.

Periodic inspection:

Regularly inspect critical components of the YiN automatic cutter, such as the cutter blades, drive system, electrical connections, etc. Check for signs of wear, loose connections, or malfunctions and make timely repairs or adjustments as needed to ensure stable operation.

Parts replacement:

For damaged or worn parts, such as cutting blades, belts, etc. It is crucial to replace them on time to ensure cutting quality and equipment operating smoothly. Use genuine replacement parts to ensure compatibility and quality.

Dust removal:

Dust and debris generated during auto cutting can affect the machine's performance and longevity. Use a vacuum cleaner or an air gun to remove dust from the machine's interior and exposed parts to keep it clean and free of obstructions.

Maintain proper environmental conditions:

Maintain appropriate temperature and humidity levels for auto cutters. Avoid exposing them to extreme temperatures, high humidity, or other harsh environmental conditions to prevent equipment damage.

Yin auto cutters are essential for the auto industry, especially during the initial garment cutting phase. Here are some common uses of these cutters:

Cutting Capacity and Size:

Assessing the cutting capacity and size is essential when choosing an auto cutter. It's about looking at how much fabric it can cut and its dimensions to ensure it fits well in a business's setup. Manufacturers need to pick a cutter that can handle the amount of material they usually work with and one that will fit conveniently in their workspace.

Precision and Accuracy:

Tip: Precision and accuracy are significant when choosing an auto cutter, particularly for those in the garment-making industry. Select a machine that offers a high level of accuracy in cutting to ensure that all pieces are cut exactly right. This will help eliminate any problems with fitting and improve overall product quality.

Ease of Operation and Software:

When selecting a cutter, consider how easy it is to operate and what kind of software it uses. Choose a device that is user-friendly, as this can significantly impact productivity and efficiency. The software's capability to manage design files and its cutting precision is also crucial, so make sure to choose one that meets specific business needs.

Durability and Maintenance:

Durability is an essential factor to consider when choosing an automatic cutter. Go for models built to withstand constant use in professional settings. Additionally, check the maintenance requirements of the auto cutter. Select machines that are straightforward to maintain and clean. Opt for those that have readily available replacement parts and service networks to ensure long-term operational efficiency.

Q1: How is a fabric auto cutter different from a traditional fabric cutter?

A1: INY cutters are automatic, controlled by a computer, and offer a high level of precision and efficiency. Traditional cutters are more manual and may provide lower precision.

Q2: Can an auto fabric cutter handle different types of materials?

A2: Yes, when equipped with the right blades and settings, auto cutters can cut various fabric materials, including delicate and complex ones.

Q3: Are YIN auto cutters easy to operate?>

A3: Yes, YIN auto cutters are typically easy to operate. They come with user-friendly software for design input and cutting control.

Q4: Can I upgrade my auto cutter machine in the future?>

A4: Yes, many auto cutters have optional upgrades, such as faster production speeds or additional software features.