All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(18730 products available)

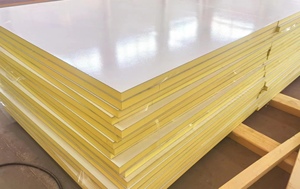

XPS panels have gained popularity in recent years due to their durability, lightweight, and excellent insulation properties. An XPS panel is a rigid foam board used in construction projects to provide insulation. It is designed to keep buildings warm during winter and cool during summer. These panels are versatile and can be used in walls, roofs, and floors. An xps panel is made of extruded polystyrene foam and is characterized by its blue or pink color. It is water resistant, has a high compressive strength, and provides excellent thermal insulation.

The types of XPS panels include:

The XPS 7 series is equipped with powerful features and functions that enhance productivity and provide an ultimate user experience. Here are some of the features alongside their functions:

Display

The laptop has a 17-inch screen with a 4-sided InfinityEdge display. It also has a touch-enabled display with a 3K resolution of 3072 x 1920. The display offers high brightness and contrast, producing vivid and sharp images. The touchscreen feature enables quick and easy navigation and control.

Performance

The laptop is powered by Intel's 12th generation core processors. It offers a choice between i7 or i9 processors. The processors provide high-performance computing for demanding applications. The processors also support multitasking with up to 16 threads. The XPS 7 series also has an option of Intel Iris Xe Graphics to enhance the visual performance.

Memory and storage

The laptop has 16GB or 32GB of RAM. This enables efficient running of multiple applications simultaneously without lagging. It also has storage options of 512GB or 1TB PCIe NVMe SSD. This ensures fast data access and boot times. The laptop also has a dedicated slot for upgrading memory and storage capacity.

Design and build quality

The Dell XPS 7 series is designed with premium materials like aluminum and carbon fiber. It has a sleek and modern design with a backlit keyboard and precision touchpad. The laptop also has a high-resolution webcam and dual speakers that offer clear sound.

Connectivity

The device has multiple Thunderbolt 4/USB-C ports. This enables fast data transfer and connectivity to external devices. It also has Wi-Fi 6E and Bluetooth 5.2 support for high-speed wireless internet connectivity. The laptop also has an optional fingerprint reader and IR sensor for enhanced security.

Battery life

The Dell XPS 7 series has a long-lasting battery. The battery can last up to 14 hours on a single charge depending on usage. It also supports fast charging via USB-C. This enables the laptop to charge up to 80% in about an hour.

The xps panel_7 comes in different sizes, making it easy to customize and install in various applications. Here are some common usage scenarios for XPS panels:

Residential Construction

XPS panels are popular in the home building industry because they are light and have excellent insulation. Builders use XPS panels to make insulated slab foundations, which help keep energy costs down. The panels are also used to make layered roofs and insulated walls. Using XPS panels in residential construction ensures houses are comfortable and energy-efficient.

Commercial Buildings

XPS panels are also used to construct commercial buildings. The panels provide sustainable insulation solutions for large buildings like shopping malls and office spaces. XPS panels have a high R-value, which makes them great for energy-efficient building designs. Using the panels reduces the need for cooling and heating, which cuts energy costs for commercial building owners.

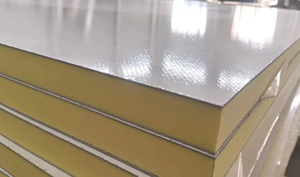

Cold Storage Facilities

XPS panels are used to build cold storage facilities because they have an excellent thermal resistance. The facilities require stable temperatures that are below the freezing point to store perishable goods. The insulation properties of XPS panels help maintain low temperatures in the storage spaces. The panels are also durable and resistant to moisture, which makes them ideal for use in cold storage.

Agricultural Buildings

XPS panels are used to construct agricultural buildings like barns and animal shelters. The buildings need insulation to protect livestock from harsh weather conditions. XPS panels provide a comfortable environment for livestock without using too much energy. This is because the panels are lightweight and have high insulation value. The panels also have a vapour barrier, which prevents moisture buildup.

Modular and Prefabricated Construction

XPS panels are used to make modular and prefabricated buildings. The lightweight nature of the panels makes them easy to transport. When the buildings are being constructed, XPS panels are easily assembled into insulated walls, roofs, and floors. Using XPS panels in modular construction reduces the time and cost of building.

When choosing an XPS panel, there are a few factors to consider to ensure that the right product is selected for a specific application. Here are some of the factors to consider:

Thermal Resistance

When choosing an XPS panel, it is important to look at the thermal resistance or R-value. The R-value shows how well the panel resists heat flow. A higher value means better insulation. If the goal is to reduce heat loss or gain, then a panel with higher thermal resistance should be considered.

Thickness and Compression Strength

The thickness of the XPS panels affects their insulation efficiency. Thicker panels generally have a higher R-value. However, the application may require a specific thickness. XPS panels come in different thicknesses. It is also important to consider the compressive strength of the panels. If the panels will be used in areas with high loads, then those with higher compressive strength should be selected.

Moisture Resistance

XPS panels have a high resistance to moisture. However, some panels have higher resistance than others. It is important to consider the moisture resistance of the panel, especially if it will be used in a wet environment like a basement or area with a high water table. Choosing a panel with a high level of moisture resistance will ensure longevity and structural integrity.

Environmental Impact

XPS panels are manufactured with different blowing agents. Some agents have a negative impact on the environment more than others. When choosing an XPS panel, it is important to consider panels that are manufactured with environmentally friendly blowing agents. This will help reduce the environmental impact.

Compatibility

XPS panels are used for different applications. It is important to ensure that the selected panel is compatible with other materials used in construction. For instance, if the XPS panel is to be used as a roof insulation panel, it should be compatible with roofing materials like bitumen, and membranes.

Q: What are the most common applications for XPS panels?

A: XPS panels are commonly used for external walls, foundations, flat roof applications, and thermal insulation in buildings and infrastructure projects.

Q: How are XPS panels installed?

A: XPS panels are installed using adhesive bonds, mechanical fasteners, or as part of a prefabricated system, depending on the application and design requirements.

Q: What sizes and thicknesses are available for XPS panels?

A: XPS panels are available in various sizes and thicknesses, with common thicknesses ranging from 1 inch to 4 inches or more, depending on the insulation requirements and regional building codes.

Q: How do XPS panels compare in cost to other insulation materials?

A: XPS panels may have a higher upfront cost compared to some other insulation materials, such as expanded polystyrene (EPS) panels. However, their superior thermal performance and long-term energy savings can make them a cost-effective choice over the lifespan of a building.

Q: Can XPS panels be recycled?

A: While XPS panels are not commonly recycled, some manufacturers and facilities may offer recycling programs for post-consumer or post-construction XPS insulation. It is recommended to check local options and programs for XPS recycling.