All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1021 products available)

There are two main types of windshield washers, namely, manual and automatic washers.

Manual windshield washers

According to windshield washer manufacturers, manual windshield washers have a simple mechanism. When the user presses the pump, water and washer fluid get pushed out through the nozzles. This action requires the user to press the pump repeatedly until the desired amount of fluid is dispensed. Manual washers are suitable for older vehicles and are less expensive compared to the automatic ones.

Automatic windshield washers

Automatic washers are controlled by a switch on the lever of the windshield wiper. Once the switch is turned on, the washer system gets activated, and the fluid is automatically dispensed through the nozzles. The user only has to turn the switch on without the need to press a pump repeatedly. The system is designed to work together with the windshield wiper motor. When the wipers are in operation, they ensure a continuous supply of fluid to the nozzles even at high speeds by creating a negative pressure. Besides, some modern cars have a rain sensor that activates the automatic washers when it detects rain.

There are also several types of windshield washer pumps, including:

Diaphragm pumps

Washer fluid is pushed and pulled through the pump's inlet and outlet ports by the diaphragm's motion, which is activated by an electric motor.

Peristaltic pumps

In this pump, the washer fluid channel is squeezed by the rollers rotating on the eccentric wheel. This action prevents any backflow of the fluid.

Centrifugal pumps

Washer fluid is pushed through the inlet and outlet ports by the centrifugal force created by the rotating impeller in the washer fluid reservoir.

Gear pumps

In the washer system, fluid is transferred from the inlet to the outlet by the rotating gears, which creates a pressure difference that drives the fluid movement.

Brushless motor pumps

These are the most common types of pumps in cars today. They are efficient, have a long lifespan, and are quieter than other types of pumps. The motor enables the pump to operate at different speeds based on the task at hand.

The following are specifications of the windshield washer system that businesses should note when buying parts:

Washer fluid

Regular maintenance requires using the right washer fluid. It has additives that prevent freezing and reduce surface tension for better pump performance. This ensures the system works efficiently regardless of the weather conditions.

Electrical components

Windshield wipers have electrical components like the washer pump, switches, and wiper motor. These components require periodic inspections for proper operation. The components also require checks for loose connections, signs of wear, and corrosion. This will prevent system failures.

Spray nozzles

Blocked spray nozzles will reduce the amount of fluid that reaches the windshield, compromising visibility. It is important to inspect the spray nozzles regularly for signs of blockages and dirt. Users should also clean the nozzles periodically to prevent build-up. In addition, the nozzles should be adjusted to ensure they are aligned correctly.

Quality washer fluid

It is important to use quality washer fluid for regular refills. This is because it contains additives that prevent freezing and block contamination of the washer system. Users should avoid DIY mixtures because they can damage the system.

Electrical connections

For electrical components to work efficiently, they must have secure connections. Loose connections can cause intermittent operation or complete system failure. It is important to inspect electrical connections regularly for signs of wear or looseness.

Wiper blades

Wiper blades need to be maintained for the windshield washer to function efficiently. The washer system will work ineffectively if the wipers are damaged, worn out, or have irregular movement patterns. Users should inspect wiper blades and replace them if they notice signs of wear.

Here are some important factors to consider when choosing a windshield washer manufacturer:

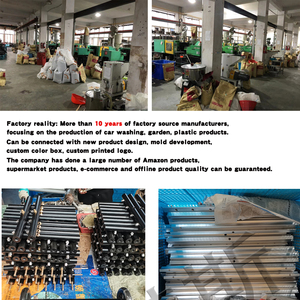

Quality and Reliability:

It is important to choose a manufacturer known for making high-quality, dependable windshield washers. Reading reviews and comments from other businesses helps understand how long the washers last and how well they work. It is also good to ask the company for samples. This allows the windshield washer to be tested before placing a large order.

Variety:

Depending on the needs of customers, it is good to choose a manufacturer that offers many types and sizes of windshield washers. Some people prefer automated ones, while others want simple, manual ones. Wholesalers can select the models that best suit their target customers. It is also good to choose a manufacturer that regularly releases new models. This way, the windshield washers stay modern and up-to-date with the latest technology.

Price:

Price is an important factor to consider when choosing a windshield washer manufacturer. Wholesalers should compare offers from different suppliers to find the best deal. However, they should not choose a manufacturer based only on the lowest price. It is important to ensure the quality and reliability of the products are satisfactory. Some manufacturers offer discounts for first-time buyers or for placing large orders. Wholesalers can take advantage of such offers to reduce costs.

Customization:

Choosing a manufacturer that provides customization options is good for wholesalers. The windshield washer can be branded with the logo of the business. The features can also be modified to meet the specific needs of the customers. It is good to discuss with the manufacturer about the available customization options and the associated costs and lead times.

After-sales service:

After-sales service is an important aspect to consider. Wholesalers should choose a manufacturer that provides timely and effective assistance after the sale. If any problems arise with the windshield washers, the manufacturer should be available to help solve the issues. Additionally, it is good to choose a manufacturer that provides a reasonable warranty for the products. This protects the investment of the wholesaler and ensures the quality of the windshield washers.

Delivery Time:

Delivery time is also an important factor to consider when choosing a windshield washer manufacturer. Wholesalers should choose a manufacturer that can provide timely delivery of products. If the delivery is delayed, it may affect the business's sales and reputation. Wholesalers should communicate with the manufacturer about the estimated delivery time and any factors that may affect it.

Although it is recommended that windshield washer system components should be replaced by a qualified mechanic, it is possible to do it at home. Below are the steps to take when replacing the pump, nozzle, and hose.

Q1: Where can one buy original equipment (OE) windshield wipers?

A1: To purchase original equipment (OE) windshield wipers, visit the dealership of the vehicle's make or contact them. Additionally, reputable auto parts stores and online retailers offer OE wipers for various car models.

Q2: What are the advantages of upgrading to premium windshield washer parts?

A2: Premium windshield washer parts, such as pumps and nozzles, often have better durability, higher pressure, and more refined spray patterns. They can improve overall system performance and reduce the need for frequent replacements.

Q3: Can the windshield washer system be used in cold weather?

A3: Yes, using a proper windshield washer fluid containing antifreeze components in cold weather is essential. This prevents freezing in the reservoir and lines, ensuring the system functions effectively even in low temperatures.

Q4: How often should windshield washer parts be checked?

A4: It is advisable to inspect windshield washer parts regularly, mainly when performing routine vehicle maintenance. Early detection of potential issues allows for timely replacements and avoids system failures.

Q5: Are there any special tips for maintaining windshield washer nozzles?

A5: Windshield washer nozzles should be kept clean and free of debris to ensure proper fluid spraying. If they are clogged, they can be cleaned with a soft brush or needle. Additionally, improper nozzle alignment can lead to uneven fluid distribution, which requires adjustment.