All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(3782 products available)

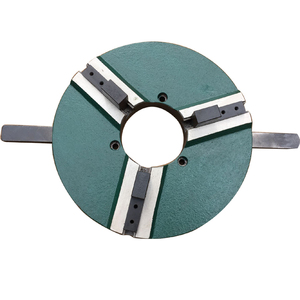

A welding chuck is a critical tool for any business working with welding. It's important to understand what variety of tool is needed and what job it is needed for in order to improve productivity.

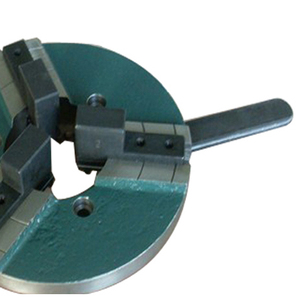

Manual welding chucks require some human input for operation; they need a locking clamp to keep the workpiece steady, so that piece can be welded as best as possible. To do this, the person will have to screw or tighten the chuck around the workpiece by either turning a lever or spinning a wheel. It is, therefore, mainly applied by small production companies, workshop settings, and mobile welding units, where only limited welding tasks are performed.

Benefits of using manual welding chucks include their simplicity, low price, and ease of use. However, since it is all done by hand, it is also very slow and could have some wrong measurements here and there compared to automated chucks.

A pneumatic welding chuck is used when something is installed and the facility for pneumatic systems is present. It works similarly to the mechanical type in that the jaws close to grip the workpiece, but instead of being operated by a person's hand, it is controlled by air pressure. Pneumatic welding chucks are used when the chance arises that high production numbers result in common tasks.

The main pros of pneumatic welding chucks is that they are efficient, they increase operation speed, and they are good for large workpieces. While efficiency is a plus, it can also be a downside since anything that breaks relies on air pressure to operate, and that can meant that day-to-day repairs can be costly and time-consuming.

A welding chamfering automatic chuck does all the work by itself when it is given a workpiece. These chucks are often put in large-scale production lines where there is a great need to quickly and efficiently weld big numbers. These chucks would open, put in the workpiece, and then shut without any help from a human. This process increased efficiency while reducing many of the possible errors.

Automatic welding chucks are very efficient and great for methodical work. However, setup can be time-consuming, often requiring a thorough understanding of how to operate the machine. Furthermore, these chucks can sometimes be prohibitively expensive due to their advanced features.

Electromagnetic welding chucks employ electromagnetic forces to stabilize and align workpieces. When energy is applied, the electromagnets, embedded in the chuck, clutch the workpiece forcefully. These chucks are used in industries that need precise positioning and alignment, such as in the manufacture of critical components or in aerospace.

The pros of this type include flexibility in gripping various shapes and sizes, as well as high precision and strong grip. However, dependence on an external power source is a definite downside, as power outages or equipment failures can result in immediate risks to productivity.

Compatibility and coupling with other systems or machinery is an important thing to consider because it impacts efficiency and also system integration.

Welding chucks, especially auto and pneumatic ones, require coupling to CNC machinery because of their automated operation. These chucks, for instance, can be used with lathes, mills, and other machining centers for more complex operations.

For companies already using CNC machining centers, selecting a chuck compatible with their existing systems can streamline operations, reducing the need for additional equipment.

For the welding chuck to perform well, it must be compatible with the type of welder being used in that particular circumstance. There might be chucks suitable for electro-fusion or manual welding, while others are constructed to handle lnduction welding. Such couples prevent fusing dissimilar apparatuses or weld qualitatively from being degraded.

Integrated welding machines often have built-in chucks, which are helpful in this situation. Although there is no welding machine built in without a chuck, do not worry; most manufacturers have a way to kit up the systems.

In industries where rotating workpieces or robotic arms are used, welding chucks can play a key role. For example, a pneumatic welding chuck could be used for a robotic arm, as this would give the arm a way of binding items so they could weld them manipulated with precision.

Similarly, in automated systems with turntables for welding, the welding chucks need to be compatible. Companies relying on robotics or turntable-based welding processes can benefit from chucks specifically designed for these applications.

Welding chucks perform differently, and a company's work output will depend on several factors, including the type of welder used, workpiece weight, and gripping force. Therefore, knowing the general specifications of welding chucks will help in the selection process:

Maintaining a welding chuck is essential to ensure its reliability, especially for businesses focusing on high-volume welding. Proper maintenance can also extend the life of the chuck, providing a better return on investment.

It's important to select the right chuck from the many available options so that the company operates at maximum efficiency.

A1: Yes, they can, especially those in smaller production work or mobile units where tasks are limited.

A2: This is because they efficiently grip workpieces at quick speeds, which is excellent for mass production.

A3: Various factors include the business's workpiece size, type of welding used, and production volume.

A4: This chuck is specifically helpful when there is a need for precision and when fragile materials are at stake.

A5: Automated and pneumatic welding chucks are suited for high production because they ensure efficiency.