Types Of Welding Chalk

Welding chalk is used to mark and help welders know where to make joints. It works better than other forms of marking, as it does not mess up the joints or affect the welding. It comes in many types, as explained below.

Tailoring chalk

Tailoring chalk is like welding chalk in many ways. Most times, it comes in the same texture and feel as welding chalk. While it is in the form of sticks like welding chalk, some come in shaped rectangular blocks. Though its primary use is for sewing clothes, it doubles as a welder's friend as well.

It comes in colors that are easy to see on most materials, yet when the job is done, it is easy to erase. The mark remains clear and bright, yet it does not stain the clothes. The shape of the stick makes it easy to grip, hence easier to make precise marks while sewing or in the case of welding, on materials. While it has the same advantages as using chalk for welding, it comes at a cheaper price.

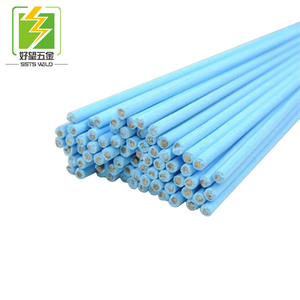

Weld pressure chalk (blue chalk for Welding)

This specific type of chalk is made for welding. It is the best option for welders who use the chalk and wipe method. Most of the time, it comes in different colors, with blue being the most common. It is good to note that the pressure chalk composition may differ depending on the company. This pressure chalk is a set of chalk sticks that come in a small toolbox and are used by professional welders.

The pressure chalk can be used with any kind of pressure chalk holder, but it is most convenient when used with the small pocket chalk holder. Pressure chalk comes in some handy colors that are strong enough to show through grime and grease. These colors include blue, black, and yellow. Pressure chalk is loved because it is local and affordable.

Automotive body line chalk

Automotive body line chalk is a special kind of chalk used in the automotive welding business. It is great for making lines straight and clean, which makes it good for the body lines of the vehicle. It comes in both thin and wide bands, and thin and thick chalk strips. The slender strips allow tailoring to narrow areas, while the broad swathes facilitate encompassing wider surfaces.

Usually, this chalk is made with a special kind of dust that does not mess up the place. The markings wash off easily and do not remain on the vehicle after the job is done. The strips are also made of strong material, so they do not cut easily when pressure or tools are applied to them.

How To Choose Welding Chalk

The following factors should be considered:

- Job requirements: When choosing the best welding chalk, think about what the actual welding job needs. If the job will be done in an outside place or at a high temp, it is better to use welding chalk that works well in those spots. Chalk for pressure or heavy work is better suited for tough jobs. For work that needs more care, choose tailor's chalk. It is better for creating thin and exact lines.

- Material type: Any heat-sensitive material should use non-heat chalk. For kinds of metal that are hard to mark, like stainless steel, it is better to use chalk that is hard to remove.

- Ergonomic design: Choose welding chalk designed for easy use. This will help reduce hand strain when marking for long hours. Chalk can come in handy shapes or have a better grip so they do not slide off in the welder's hands.

- Refillable vs. disposable: Disposable welding chalk is best for quick jobs, while refillable welding chalk is better for long-term use. It helps welders save money and will not run out while working on big jobs. It allows for using different kinds of chalk to suit the job needs.

- Dust resistance: In a working place that creates a lot of dust, some dust-resistant chalk is better. Dust can easily smear lines if there are no measures against it. Dust-proof welding chalk will keep marks clean even with strong wind or other conditions that cause dust.

Industrial Applications Of Welding Chalk

- Shipbuilding: Welders use chalk to outline joints for large hulls and structures so that the welding is precise. The leads to stronger ships that do not crack under pressure.

- Aerospace: In aircraft assembly, welding chalk shows where the steel reinforces supports for an ultra-light frame. It does not weigh down the aircraft, so it can fly higher and faster than regular aircraft.

- Pipelines: For pipe welding, chalk indicates stresses along the curved joints to prevent leaks. It saves thousands in repairs by ensuring optimal flow within the pipes.

- Automotive: Chalk outlines welds along body panels to ensure smooth assembly and a sleek finish on modern vehicles. This make the vehicle look better and drive faster without wasting fuel.

- Construction: Steel framing requires accurate welds at right angles to support heavy loads. Chalk shows where one piece connects to the next for strong building skeletons. It enables taller, safer structures to hold more floors than older models.

- Metal fabrication: Chalk marks cuts and joints on sheet metal to guide custom builds for signage and enclosures. This Versatility enables unique designs not possible with stock components.

Product Specifications And More

Welding chalk comes in a few formats, as outlined below:

- Chalk strips - Width: 0.5 inch (1.27 cm); Length: 36 inches (91.44 cm); Marking area width: 0.75 inch (1.9 cm); Material: Dust-resistant chalk.

- Chalk sticks -Width: 0.25 inch (0.64 cm); Length: 5.5 inches (14 cm); Sturdy and durable; Colors: Yellow, white, red, blue.

- Tailor's chalk - Size: 1.5 x 2.5 inches (3.8 x 6.3 cm); Used for marking fabrics; Harmless to fabrics.

Withstands high pressure; Ergonomic nonslip grip; Fast release; Master lock promotes control; Compact dimensions; Weighs around 0.95 lbs (0.43 kg).

Manufacturer: استخدم طراز Umihico 2023-فو كرافت كو. Islands 2448, 70719323813.

- Chalk strips - Width: 0.5 inch (1.27 cm); Length: 36 inches (91.44 cm); Marking area width: 0.75 inch (1.9 cm); Material: Dust-resistant chalk.

- Chalk sticks -Width: 0.25 inch (0.64 cm); Length: 5.5 inches (14 cm); Sturdy and durable; Colors: Yellow, white, red, blue.

- Tailor's chalk - Size: 1.5 x 2.5 inches (3.8 x 6.3 cm); Used for marking fabrics; Harmless to fabrics.

Accessory information includes:

- Handheld chalk holder - Material: Aluminum; 4-inch grip for comfort; 5-inch barrel holds large sticks.

- Refillable mechanical chisel - Weight: 1 lb (0.45 kg); Length: 7 in (17.8 cm); Uses standard chalk inside.

- Pocket chalk box - Box size: 4 x 3 x 1 inch (10.2 x 7.6 x 2.5 cm); Holds sticks and snap tip; Small and portable box.

How To Use

- Cutting: To cut the metal into desired sizes, mark the metal sheet using this chalk and then use a cutting torch.

- Tacking: Position the pieces as per the instructions and attach temporarily (tack weld) at joints using just enough weld to secure in.

- Welding: Following same joint lines, fully weld each seam, fusing two metals together as one. Proper welds provide strength and durability necessary.

- Cleaning: Allow weld to cool, then utilize metal brush or grinder to remove slag/cool stuff from joint area for inspection and test purposes.

Q & A

Q. What makes pressure chalk different from regular chalk?

A: Pressure chalk is denser than regular chalk. Therefore, it creates sharper lines and can be used on rough surfaces.

Q. Can chalk markings be left on steel for a long time?

A: Normally, chalk markings can be left on steel for a month. After this period, the marking may be hard to remove. Clean it before the chalk dries on it.

Q. Is handmade chalk better for marking than machine-made chalk?

A: Handmade chalk makes thicker lines that do not break easily, and it is easy to erase. This makes marks permanent and harder to erase. Machine-made chalk is precise but fragile, making the mark hard to erase.

Q. Can children use welding chalk?

A: The chalk is not safe for children as it contains small particles that can harm children when ingested.