All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(4337 products available)

Rubber Wheels

In the context of welding cart wheels, rubber wheels are dominating due to the advantages they possess. The main features of rubber wheels are their excellent shock absorption, noiselessness when in use, and their non-scratch ability. These characteristics is suitable for maneuvering rather than welding equipment over varied ground surfaces. The flexibility of rubber wheels allows them to easily over come obstacles on the ground. Because of this, they are used in areas where the cart is required to move frequently from one place to another, including the workshop or construction site.

Plastic Wheels

The most important and basic characteristic of plastic wheels is their lightweight construction. These wheels are made from a material that is light meaning they can be easily operated with less effort. There are two other qualities to consider: they are also inexpensive and therefore do not dent or scratch floors. Nonetheless, plastic wheels have certain disadvantages when compared to the other types of wheels: they are less stable and won't withstand high temperatures or heavy weight. Plastic wheels are suitable for light welding carts which will be used in areas of flat and stable flooring.

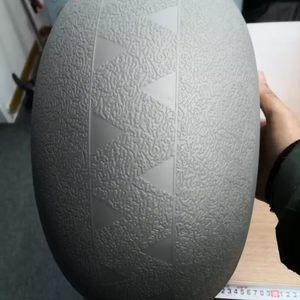

Metal Core Sleeved in Rubber

Metal cores wrapped in rubber wheels combine the advantages of strength and flexible. The rigid metal core provides the cart with heavy loads that need to be carried, and the rubber outer layer enables movement over the ground. These wheels are best used in the settings that require a combination of mobility and stability, for example in the workshops with not very even floor. These wheels are also very durable and would stand wear and tear very well.

Foam-Filled Wheels

Foam-filled wheels are designed to prevent punctures by including an internal foam structure within a thin outer layer of tire. The wheel functions just like the tire but without the drawback of inflation, thus making it ideal for rugged environments with a risk of punctured tires. They have medium flexibility: good enough to absorb some shocks, but not as good as pure rubber wheels. These cart wheels are ideal for outdoor use, especially on rocky or uneven terrain, where punctures are a likely occurrence.

Manufacturing

Welding cart wheels help in easy movement of tools and materials within the manufacturing plants. They virtually ensure that heavy loads are moved with ease by their strength and durability.

Construction

In construction, welding carts are used to move welding machines, gas cylinders, and other heavy equipment from one area to another. Such a convenience is provided especially if the site conditions are tough, which makes having wheels crucial for making a task easier.

Automotive Industry

The cart wheels are crucial in the workshops engaged in auto repairs, as they facilitate the transportation of welding devices and heavy components. They are particularly helpful when major work involves moving items around frequently.

Aerospace

Welding cart wheels are used in the aerospace sector, where precision and care are of utmost importance. In this case, carts must support heavy weights while gentle on sensitive components.

Shipbuilding

Because shipbuilding occurs on a large scale, welding cart wheels transport tools and equipment across vast spaces. With their strength and resistance to including water, the wheels make it possible to work with boats and their surroundings.

Welding Industry

Almost all welding industries employ welding cart wheels due to their great importance for the movement of welding machines and accessories either within the workshop or on site. Their design and strength should be given special considerations depending on the kind of terrain they are used on.

Durability

They should, therefore, support the weight and rigors of the operations they are subjected to, including the heavy welding machines, tools, and gases. This means that good wheels must be made of strong materials, such as rubber or metal composites, that have good wear and tear as well as temperature resistance. Any cart with wheels designed for extreme working conditions should feature shock absorption, puncture resistance or even corrosion resistance.

Mobility

The shaping of a welding cart wheels is its fundamental virtue, since this determines where and how the cart can traverse, balance the load, and rotate. Provided are wheels of such design that allow them to run smoothly over flat as well as rough floors and accommodate steering, for example, casters in the front and fixed wheels in the rear. Small caster wheels provide more control, while large wheels reduce floor contact for obstacles.

Versatility

Welding cart wheels find applications in welding carts and other heavy equipment trolleys, tool chests, or gas cylinder carts. Due to that, their size, load rating, and compatibility with various axles are concerned.

Durability and Material

The cart wheels for welding require durability since the wheels will be subject to heavy loads and, most probably, heat during the welding process. Because of this, they should always be made of durable materials such as rubber, which has a very high wear resistance, and which absorbs shocks very well. In such circumstances, wheels fitted with a metal core are also advantageous because they increase the strength of the wheel and at the same time allow the ease of motion.

Wheel Size and Terrain Compatibility

Welding cart wheels should be sized around the cart's size and the terrain over which it is expected to operate. Larger wheels are appropriate for irregular and rough surfaces since they provide better ground clearance and maneuverability. Bumpy surfaces also necessitate the use of large wheels, which may be up to 10 inches in size. On the other hand, should the cart be operated on a flat surface, smaller wheels would suffice, making the cart easy and more efficient to maneuver.

Load Capacity

Load capacity is also critical, as the cart must carry a welding machine, gas cylinders, tools, and other equipment. The wheels should also be capable of carrying more than the total weight of the cart and all its contents. In the case of heavy-duty tasks, the wheels must be larger in diameter and thicker and preferably constructed from more rigid materials. Lighter tasks will call for smaller, lighter wheels.

PunCtion Resistance

Puncture resistance is also an important factor when the cart will be used in outdoor environments where exposure to sharp objects and rough terrain is likely. Wheels featuring puncture-proof designs, such as foam-filled or solid rubber, will stand such hazards better. While standard pneumatic tires do offer a smooth ride, they are, however, susceptible to puncture and, therefore, not suitable for such working conditions unless adequate measures are taken for a quick repair.

Noise Level

Finally, considering the noise level as one of the factors when choosing welding cart wheels is important, especially in environments where noise should be minimized. Quiet operation is one of the outstanding features of the rubber wheels since their surface is not hard like those of metal; thus, they do not produce as much noise when carrying a load as do hard metal casters.

A: Rubber wheels are better since they absorb shock better, are quieter, and do not scratch the floor. Plastic wheels may lack strength and temperature resistance, hence not suitable for heavy-duty or high-temperature working environments.

A: Typically, these wheels size varies between 5 inches and 10 inches with the smaller wheels suitable for flat and indoor surfaces and larger ones for outdoors and rugged terrain.

A: While advantageous because of smooth running, pneumatic tires are vulnerable to puncture. They are suitable for flat and indoor areas, but other options like foam-filled or solid rubber are better for outdoor use with sharp objects.

A: One has to pick appropriately sized wheels with a higher load capacity and ensure the materials used are strong enough. Higher weight means using large wheels, thicker wheel hubs, and axles.

A: When cart wheels have to be used in a welding area, they must be made to resist high temperature, as any failure in this regard will cause the wheels to degrade. Wheels made of heat-resistant materials or having a thermal shield are well suited for high-temperature environments.