All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(177 products available)

Weir flow meters can be made in various types, suitable to measure the fluids in differing processes. This way, the precise volumetric flow rate can be determined in most of the applications.

A V-notch weir flow meter uses a V-shaped notch as the outlet through which the liquid flows. Such a type is especially suitable for flow measurement in wastewater treatment and process industries where fluids are viscous. The corner angle of the V-notch is typically 60°, with notches of 10 mm, 20 mm, 40 mm, and 80 mm. A fluid level measurement is transmitted by the piezoresistive level transducer to a flow converter. The flow equation for a 60° V-notch weir is:

Q = 2.84H^(5/2), for SI units

Q = 0.278H^(5/2), for US unitsU-shaped weir flow meters use a U-shaped weir to measure flow in open channels. Commonly used in sewage treatment plants and large industrial lagoons, the weir can be shaped in a semicircular, triangular, square, trapezoidal, or parabolic cross-section. U weirs are suitable for measuring flow volumes in channels and ponds in low-flow and high-flow conditions. More importantly, such weirs produce accurate flow rate results in all flow conditions. In addition, the flow calculations are based on the two most common U weir shapes, rectangular and circular.

The circular flow meter comprises a circular section whereby the outflow passes the liquid through beneath the inlet. The circular arc-shaped weir is well suited for accurate flow measurement in small spaces, such as in the wastewater collection system. Circular weirs are generally resistant to variations in flow rates and produce accurate measurements. This makes them suitable for measuring flow in small pipelines or drainage systems.

Broad-crested weirs are similar to V-notch, but in this case, the top edge of the weir is flat. A broad crest weir flow meter is largely applied when measuring liquid flow in open channels with a steady flow condition. It is widely applied in hydraulic engineering and water resource management areas, especially in irrigation ditches and ponds. Because of having a broader edge than the V-notch weir, it reduces the range of fluctuation of the liquid level, thus being suitable for high flow measurement.

The choice of the material for the housing of the Weir flow meter would depend on the medium to be measured. While stainless steel is often used as it is highly resistant to corrosion, many are also made from brass or aluminum. Where pricing is the main concern, many manufacturers will also house their Weir flow meters in engineering plastics such as polycarbonate.

Weir flow meters measure the flow of liquids through an outlet weir by the height of fluid above the weir. As the fluid flows over the weir, it forms a small stream that increases proportionally to the height of the fluid. The greater the fluid level, the more the flow rate.

Some of the measuring principles of the weir flow meter include:

Level and Flow Rate Relationship

It works by measuring the distance between the fluid level and the height of the weir. This is done using a pressure transducer or an ultrasonic sensor.

Flow Calculation

A flow conversion formula is used to convert the fluid height level into the flow rate. Parameters within the formula include the type of weir and the fluid properties.

Weir flow meters have been around for a while and have undergone some design improvements to increase measurement accuracy. Some of the common design components include:

Rim

Most weirs have a lip or rim on the top. This helps make the flow over the weir more stable.

Shape

Weirs can be of different shapes like a rectangle, V-notch, or trapezoid depending on their application. Each shape is suitable for a particular flow rate range.

Sensors

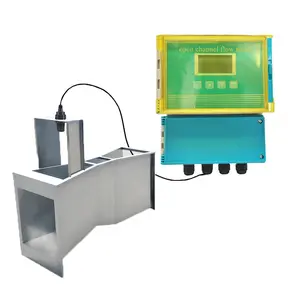

To measure the fluid level accurately, many modern Weir flow meters will attach pressure or ultrasonic sensors.

Weir flow meters are vital for controlling inflow and enhancing treatment efficiency in wastewater facilities.

Weir flow meters measure discharge in irrigation channels, helping farmers optimize water supply for crops. They ensure proper water distribution, improving crop yields and reducing wastage.

In mining, they monitor water flow in treatment ponds and tailings areas. This flow measurement helps prevent overflow and environmental damage while ensuring safety in mining operations.

They are used to measure water flow in temporary ditches and drainage systems during construction work. Hence, they help prevent flooding and keep work sites safe and manageable.

In hydroponics, they measure nutrient solution flow, ensuring plants receive the right amount of water and nutrients. Therefore, they help maintain healthy plant growth in soil-less farming systems.

They help homeowners monitor pond or pool water levels to prevent overflow problems. This monitoring protects property and keeps water features in balance.

Weir flow meters provide data on streamflows, supporting studies of water quality, ecosystem health, and the effects of climate change on water systems.

Similarly, these flow meters measure water levels in rivers and channels. They enable timely warnings and proactive measures against potential flooding.

Thus, they are valuable in factories for measuring chemical or water flow in production processes. This application helps maintain the right flow rates, which means that production stays consistent and safe.

The weir flow meter should properly function with a head size of between 0.5 to 1.0 feet for more effective performance. However, some are capable of operating larger heads of up to 5.0 feet.

Regarding accuracy, it is better to select a flow meter with 3% accuracy.

The weir height should be within the range of 0.5 to 2.0 feet. This makes the size practical for most applications.

Some flow meters can calculate a flow rate of up to 20 gallons per minute, while others can calculate up to 500 gallons per minute.

The most common construction materials include stainless steel, plastic, and aluminum.

They should come with an IP65 rating for protection against dust and water. Opt for those with higher ratings of IP68 for water submersion.

The measurement output for most Weir flow meters is 4-20 mA, which is quite standard, while others are 1-5 volts.

The most common operational temperatures for flow meters are -4 to 158°F, with some extreme types that go up to 194°F.

Most of the Weir flow meters have – a horizontal, vertical, or inclined installation angle.

There are several factors that might affect the precision of the Weir flow meter. These factors include low-flow conditions, debris or sediment on the weir, changes in fluid density or viscosity, and improper installation. Others are fluctuations in the height measurement of the weir and changes in the angle of the fluid approaching the weir.

The V-notch is easier to install and handle than the U weir. U weirs, on the other hand, are appropriate for high-flow scenarios. Both are useful depending on the industry. For example, the V-notch weir is ideal for the wastewater treatment and process industries.

Extreme temperature and pressure can alter the flow meter accuracy. High pressure increases fluid density, which can cause velocity changes. On the other hand, high and low temperatures alter fluid viscosity. This will either increase or decrease flow rate.

This makes them especially suited for thin to moderately thick liquids. These include water, chemicals, and wastewater with solid suspensions. However, they are not recommended for highly viscous fluids that can coat the weir.

Less frequent flow checks mean the system can be neglected more. However, for the sake of the user, they should ideally be checked every five years. The five-year inspection schedule demands that any flow check can be accomplished quickly and easily.

One of the biggest concerns in a Weir flow meter is debris. This is because anything that blocks the weir can affect accuracy. Luckily, some weirs come with screens or guards to prevent larger debris from messing with the flow.