(2572 products available)

A water pipe temperature sensor is a device used to measure the temperature of water flowing through pipes. It is commonly used in various industries and applications, such as HVAC systems, plumbing, power plants, and water distribution networks. There are various types of water temperature sensors. They include:

Thermocouples

Thermocouples are water pipe temperature sensors that are made of two dissimilar metals that are joined together at one end, forming a junction. The junction generates a voltage that is proportional to the temperature difference between the junction and the other end. They are widely used as water temperature sensors because they can measure a wide temperature range, are durable, and respond quickly to temperature changes.

Resistance Temperature Detectors (RTDs)

RTDs are water pipe temperature sensors that use the principle that the resistance of certain metals, such as platinum, changes with temperature. They are known for their accuracy and stability, making them suitable for applications where precise temperature measurements are required. However, they are more expensive and have a slower response time compared to other temperature sensors.

Thermistors

Thermistors are water pipe temperature sensors that have ceramic materials whose resistance changes significantly with temperature. They are highly sensitive to temperature changes, making them suitable for applications where precise temperature control is necessary. Thermistors are typically used in smaller water pipes or where space is limited due to their small size and low cost.

Semiconductor Temperature Sensors

Semiconductor temperature sensors are water pipe temperature sensors that have low-cost integrated circuit (IC) sensors whose output is proportional to the temperature. They are suitable for applications where temperature monitoring and control are required but not necessarily high accuracy. Due to their small size, they can be easily integrated into water pipe systems.

Infrared Temperature Sensors

Infrared temperature sensors measure the temperature of the water pipe's surface through the infrared radiation emitted by the pipe. They are non-contact sensors, making them suitable for applications where contact with the pipe is not feasible or where the water is corrosive to traditional sensors. However, they are less accurate for measuring water temperature in cases where the pipe's surface temperature differs from the water's temperature.

Bimetallic Temperature Sensors

Bimetallic temperature sensors are water pipe temperature sensors that consist of two dissimilar metals bonded together in a coil. The coil deforms in response to temperature changes, which can be used to activate a switch or indicator. They are simple and reliable but not suitable for applications requiring precise temperature control due to their relatively broad temperature range.

Water pipe temperature sensors are critical components used in various applications, particularly in watercraft and cooling systems. These sensors monitor the temperature of water pipes to ensure optimal performance and prevent damage from overheating or freezing. Like any other part, the water pipe temperature sensor has specifications that must be understood to facilitate better decision-making when sourcing for such products.

Operating Temperature

The operating temperature refers to the range within which the sensor can accurately measure temperatures without being affected by the sensor's performance. For water pipe temperature sensors, the typical operating temperature range is between -40 °C to 150 °C (-40 °F to 302 °F). This range allows for monitoring temperatures in various cold and hot water pipe systems.

Temperature Measurement Accuracy

Accuracy is a critical specification for any temperature sensor, including water pipe sensors. The accuracy of these sensors typically has a margin of error of ±1 °C (±2 °F). This level of precision ensures reliable temperature monitoring and control, minimizing the risk of system failures due to temperature fluctuations.

Response Time

Response time is the time taken by the sensor to reflect a temperature change in the reading. For water pipe temperature sensors, response time is crucial as it affects the system's ability to react to temperature changes promptly. The response time for these sensors is typically in the range of 10 to 30 seconds, depending on the sensor's design and the installation's environmental conditions.

Sensor Construction Material

The construction material of the water pipe temperature sensor can affect its durability and corrosion resistance in various water pipe systems. Common materials used in these sensors include stainless steel, brass, and plastic. Stainless steel is widely preferred due to its excellent corrosion resistance and mechanical strength, making it suitable for harsh environments and high-pressure applications.

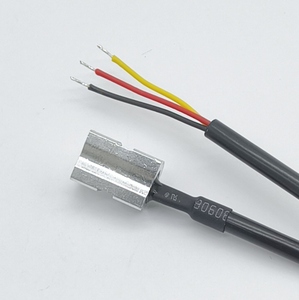

Wiring and Electrical Connection

Water pipe temperature sensors usually have two or more wires for electrical connections to the monitoring and control systems. The wiring configuration may vary depending on the sensor type and the specific application requirements. Common wiring configurations include 2-wire, 3-wire, and 4-wire setups. The wire's gauge and insulation type should also be compatible with the sensor's operating environment and the connected system's requirements.

Like any other sensor, the water pipe temperature sensor requires regular maintenance for longevity. Here are some tips:

Before buying a water pipe temperature sensor for sale, it is important to understand the factors that affect the performance of these sensors. Here are some of them:

Application Requirements

Consider what the temperature sensor will be used for. Is it for a water pipe in a residential setting, industrial piping, or a plumbing system in a large commercial building? Different applications have different temperature monitoring needs. For example, industrial water pipe sensors need strict temperature control to avoid dangerous situations like pipe explosions from superheated steam. Determine the temperature range, accuracy, and response time required for the specific application.

Compatibility with Existing Systems

Check how well the new water pipe temperature sensor will work with other systems already in place. This includes things like control systems, monitoring systems, and data logging systems. The sensor should be able to communicate easily and send information to these systems without problems. Think about what kind of output signals it should have, like 4-20mA, Modbus, or Ethernet, to connect to the other systems.

Installation and Maintenance

Think about how easy it will be to install and take care of the sensor. Some sensors need special mounting or more work to install than others. Choose sensors that are easy to install on water pipes without a lot of extra work or special tools. Also, inspect how often the sensor will need maintenance, calibration, or replacement parts. Go for sensors with low upkeep needs, saving time and money in the long run.

Environmental Conditions

Assess the environmental conditions where the sensor will be installed. Consider factors such as temperature extremes, humidity levels, exposure to corrosive substances, vibration, or electromagnetic interference. Choose sensors designed to withstand these environmental conditions to ensure reliable performance and longevity.

Budget and Cost of Ownership

Consider the initial cost of the sensor and the long-term cost of ownership, including installation, maintenance, calibration, and potential downtime. While selecting a sensor that fits the budget for the project is essential, consider the overall value regarding reliability, accuracy, and durability.

Supplier Reputation and Support

Research the reputation of the supplier or manufacturer of the water pipe temperature sensor. Look for reviews and feedback from other customers to know the quality of the product and the level of customer service. A reliable supplier should give timely technical support, help with installation, and a good warranty or guarantee.

Safety Standards and Compliance

Ensure that the water pipe temperature sensor complies with applicable industry standards and regulations. Look for certifications such as CE, RoHS, or ISO to ensure the sensor's quality and reliability.

Here is a basic guide on how to DIY and replace a water pipe temperature sensor:

Q1: Where is the water pipe temperature sensor used?

A1: The water pipe temperature sensor is used in various locations where monitoring and control of water temperature is important. This includes monitoring the temperature of water in the pipes to ensure safety and efficiency in the operation of heating or cooling systems, monitoring the temperature of water in the pipes to make sure the temperature is consistent for comfort and to avoid damage to the building's plumbing system, monitoring the temperature of water in the pipes to ensure the temperature is consistent to prevent damage to equipment and ensure optimal performance, and monitoring water temperature in agricultural irrigation systems to optimize water use and ensure optimal conditions for plant growth.

Q2: What is a water temperature sensor?

A2: A water temperature sensor is a device used to monitor and measure the temperature of water in various applications such as water pipes, water tanks, and bodies of water. It provides real-time temperature data that can be used for monitoring, control, and automation purposes. Water temperature sensors are used in various locations to ensure the safety and efficiency of temperature-sensitive processes and systems.

Q3: How does a water pipe temperature sensor work?

A3: The water pipe temperature sensor works by detecting the temperature of the water flowing through pipes and sending this information to a control system. This is achieved using various methods such as resistance temperature detectors (RTDs), thermocouples, or thermistors, which change their electrical resistance based on temperature. The control system can then use this data for monitoring and control purposes, ensuring the water temperature is maintained at the desired level.

Q4: What is the importance of monitoring water pipe temperature?

A4: Monitoring the water pipe temperature is important to ensure the safety and efficiency of various systems such as heating and cooling systems, plumbing, and industrial processes. It helps prevent damage to infrastructure, ensures optimal performance of equipment, and maintains desired conditions for processes and systems. Additionally, monitoring water temperature can help save energy and reduce operational costs by optimizing the performance of temperature-sensitive systems.

Q5: Can water pipe temperature sensors be integrated with other systems?

A5: Yes, water pipe temperature sensors can be integrated with other systems such as building management systems, heating, ventilation and air conditioning (HVAC) systems, and industrial control systems. This allows for centralized monitoring and control, enabling automation, data logging, and remote access, which can enhance the efficiency, safety, and convenience of various processes and systems.