All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(63678 products available)

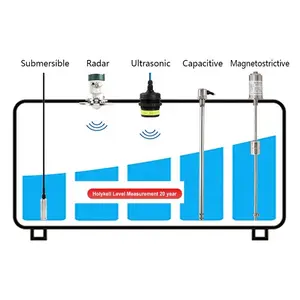

There are several kinds of water-level sensors available, and all of them work on different principles to measure water level, with each finding unique application. Water level sensor supplies are an important device used in numerous industries. Hence, understanding the various types is critical to making informed decisions. The following are the most common variants:

Mechanical Sensors

Mechanical water level sensor kits measure level by using floats or plungers which move in accordance with the water level and which actuate mechanical switches. One example is a float switch that opens or closes a circuit depending on whether the float is at a high or low point in the water tank. Such a simple design often finds its application in small-scale operations due to its robustness and ease of installation. However, it has limited use when applied in systems that require constant level monitoring, as it can only provide on/off indications.

Ceramic Pressure Sensors

Ceramic pressure sensors are one of the most advanced gadgets today, as they use strong but thin ceramic material to measure the pressure exerted by a liquid column. The pressure is directly proportional to the water depth, which can be translated into level measurement. These sensors are very accurate and immune to corrosive and harsh environments. They are commonly used in oil and gas and chemical industries where accuracy and reliability are absolutely paramount. Ceramic pressure sensors have long life and can be used where conventional methods would fail because of extreme conditions.

Capacitive Level Sensors

These sensors work by measuring the changes in capacitance, which occurs when the dielectric value of a sensor's environment changes. They are generally mounted on a vessel's wall and are appropriate for use in non-contacting level measurement. These sensors are suitable for solids and liquids, despite being primarily used for detecting liquid levels in containers. They are very effective and often employed in food and beverage, pulp and paper, and petrochemical industries due to their accuracy and minimal maintenance. They are useful for thin or small measurement ranges since they can detect level changes in very thin increments.

Water Treatment Facilities

Water level sensors are widely used in water treatment facilities to help in the control of water levels in various tanks and reservoirs. They offer accurate measurements which enable operators to balance the treatment process and avoid overflow or dry running of equipment. Also, these sensors help optimize the use of chemicals and energy by making sure the water levels were just right during the treatment process. In addition, water-level sensors provide feedback that automates pumps and valves, which improves efficiency and reduces lots of human input. It is obvious that level measurement is crucial to the safety and reliability of water treatment operations.

Building Management Systems

Buildings with complex management systems incorporate water-level sensors to control the water supply systems and prevent flooding in basements or other areas. In addition, these sensors help in the maintenance of optimal levels in cooling towers, which is crucial for HVAC operations. By giving real-time data on the water level, they enable timely actions to be taken, thus avoiding damage to properties and increasing work efficiency.

Agricultural Irrigation Systems

These sensors have a great impact in the agricultural sector, as they are used to measure the water level in irrigation ditches to maintain adequate water supply to crops. This not only helps to prevent water levels from being too high or too low, which would damage the crops, but it also helps farmers to be more efficient in their water usage. These sensors give an opportunity to automate irrigation systems, cutting down on labor and ensuring that crops receive the proper amount of water. In this case, sensor technology plays an important role in sustainable farming practices and crop health maintenance.

Vehicle Fuel Tanks

Water-level sensors are widely used in automobile fuel tanks to indicate the fuel level to the driver through the fuel gauge. In addition, these sensors allow the vehicle's onboard diagnostic system to monitor the fuel level and calculate the amount of distance that can be driven with the available fuel. Level sensors for water feature integration with telematics systems that track fuel use and availability. This contributes to safety and efficiency in the operations of a motor vehicle by monitoring fuel levels properly.

Industrial Process Control

Water level sensors are widely used in process engineering to maintain chemicals and water levels used in production. For example, balance and accurate measurement of level ensure that mechanical parts do not get damaged as a result of overflows and also guarantee quality of product. In many industrial plants, water level sensors have been linked to the automation of valves and pumps, which results in savings of cost and labor. These sensors provide critical information that ensures the processes run smoothly and safely.

Real-Time Monitoring

Water-level sensors give operators instant feedback on whether the water levels are too high or too low. This real-time measurement is important in many settings where water balance is critical to operations. Not only do these sensors reduce the risk of overflow, but they also eliminate the need to monitor water levels manually, which can be time-consuming and less reliable. Whether in industrial process, vehicle fuel tanks, or agricultural fields, having the ability to make quick adjustments based on real-time data helps to prevent damage and downtime.

Automatic Alerts

Water-level sensors are specially designed to detect danger on water levels and provide timely notifications before a major catastrophe occurs. High and low alarm thresholds can easily be set, and any breach of these levels will activate an alert, usually through visual and audible channels. This feature is very important in avoiding conditions such as overflow, flooding, and dry running of pumps which can cause serious damage to mechanical equipment and infrastructure. Early warning helps the people concerned to react appropriately and avoid undesirable incidents.

Durable and Weatherproof

A great majority of water level sensors are very strong, and some even come equipped with weatherproof housings and corrosion-resistant materials, thus making them ideal for outdoor or hazardous applications. They have a number of such features as added benefits, including extreme temperatures and water exposure, which ensure continuous operation without any effect on performance at all. Proper durability is desired in industries such as construction, oil and gas, and wastewater treatment, where the working conditions can be very harsh indeed. Because of this, reliable monitoring gives added value in critical situations.

Versatile Applications

These sensors can measure the level of water in a reservoir, fuel in a tank, hold true for industrial processes, and work well when used in agricultural irrigation systems. They work well with both static and dynamic liquids and can be used in both enclosed spaces and outdoors. With their versatility in application, they are integral to water management in different spheres, from commercial buildings to manufacturing plants and farming enterprises.

Choose the Right Sensor

Select a water level sensor that suits the application. For example, a capacitive sensor is suitable for measuring high water purity, while a pressure sensor would be better applied for use in a deep tank.

Determine Mounting Location

Find the appropriate mounting position: the optimal position for mounting the sensor is at the level where the water normally reaches in the tank or vessel. The position chosen must ensure that the sensor is kept dry at all times when water is absent.

Prepare the Tank or Vessel

Clean the area of the tank or vessel where the sensor will be mounted to avoid interference with the sensor's readings. This is done by wiping the area clean or, if necessary, removing the mounting hardware.

Mount the Sensor

Install the sensor into the tank or vessel by either drilling a hole for insertion or using an existing opening. The sensor must be mounted securely to avoid accidental dislodgement during routine operations.

Connect Wiring

Refer to the manufacturer's manual for guidance on how the sensor should be wired. Ensure the power supply and output connection are done electrically to avoid short-circuiting or other electrical problems.

Integrate with System

After installation is complete, connect the sensor output to the display or control system that requires it for level monitoring or to give an alert. Calibration should also be done to ensure correct measurements are made and proper functioning for the application concerned.

Regular Inspection

Frequent inspection of the sensor should be done so as to find any physical damage, disconnect, or wear that will affect the operation. Regular checks will ensure that problems are identified at the very early stage before they escalate into big issues.

Check Wiring and Connections

Period maintenance should be done to ensure that all electrical connections are clean and secure. Corroded or loose wires can affect the performance of the device and may lead to erroneous readings. Replacing or repairing damaged wiring is essential for maintaining the operational capacity of the sensor.

Clean the Sensor

Always ensure that the sensor is clean, particularly in those applications where debris, sediment, or buildup can interfere with readings. A simple wiping or washing may be all that is required to keep it working correctly. Cleaning the sensor regularly helps to maintain its accuracy and extend its life.

Test Functionality

Once the system is in operation, test the sensor by manually checking the water levels to see if readings correspond. Any discrepancies should be addressed and calibrated properly to ensure accurate measurements all the time.

Follow Manufacturer Guidelines

As far as maintenance is concerned, always refer to and adhere to the maintenance instruction procedures provided by the manufacturer of the water level sensor. These instructions include specific care and servicing details that would extend the life of that particular model.

Check for Certification

Water-level sensors normally have quality and safety certifications such as ISO or CE, which are indicative of conformity to defined international performance standards. This ensures that the product meets a variety of quality and safety requirements and thus gives users confidence in using it. When making a decision, the availability of these certifications shall be considered, as it ensures that the product meets all the required standards.

Monitor Installation Quality

Safety issues and sensor performance are supported by good-quality sensor installation. Proper mounting and wiring ensure accurate measurements and eliminate electrical hazards. Just following the manufacturer's directions during installation will lessen the chances of operating problems and make it work safely and effectively.

Assess Operating Conditions

Take into account all the factors that will affect the sensor's safety and quality in regard to its working environment. High temperatures, extreme pressures, or exposure to chemicals will degrade a sensor over time. It is wise to select one that has corrosion-resistant materials or has weatherproof housing, as these will apply to harsh environments and prevent failure early.

Electrical Safety

Level sensors in water should be handled with care, particularly when it comes to wiring and electrical connections. The electrical connection should be insulated properly to prevent short-circuiting and shock. Period checks on the electrical system also help to ensure that there are no hazards in the system, thus promoting safety in the operation of the water level sensor.

Maintenance for Safety

Regular maintenance of the water level indicator helps to ensure that it operates safely and at its peak accuracy. Frequent cleaning, checking for damage, and testing functionality can detect possible hazards and performance issues before they affect either safety or operations.

A1: A water level sensor tracks the liquid measurement in any given area, be it an open space or a closed space. It is used to prevent overflow, equipment damage, and water scarcity by regulating the water levels within the particular reservoirs, tanks, or containers.

A2: While different types have their working principle, generally, water level sensors work by detecting water presence and measuring the height or pressure of the water in a tank. Floating type sensors move with the water level and switch on or switch off at preset levels, while capacitive and pressure sensors measure the changes induced by water at the sensor level.

A3: Most water-based sensors are designed with weather-resistant enclosures, corrosion-proof materials, and other durability features, making them suited for outdoor applications. They are useful in such industries as construction, agriculture, and waste treatment, where the working environment is extreme.

A4: Regular checks, cleaning of the sensor, ensuring that electrical connections are secure, and testing the functionality constitutes a standard maintenance program. Following the manufacturer's instructions regarding maintenance will, in particular, ensure that the sensor operates safely and accurately.

A5: Sensors for water level measure the water levels and send the corresponding signals to controllers, which then open or close valves, turn pumps on or off, and do other things. This integration helps in automating water management systems to cut down on manual work while ensuring safety and operational effectiveness.