All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1028 products available)

Variable frequency drives (VFD) come in unique configurations. They control motor speed and torque. Some frequent types of VFDs for 200 kW include the following.

These drives adjust the frequency and voltage of changing currents. They control motor speed with high precision. These VFDs suit complex HVAC systems.

Direct current drives manage the speed of DC motors. Their motor control design allows this. These drives offer simple applications like conveyors. Users employ these VFDs in operations requiring less power.

Users employ static drives for smooth operations. They convert AC to DC and back to a different AC configuration. These drives are ideal for systems reducing energy peaks. Also, they work in industries with varying loads. Common systems include rolling mills.

Users deploy servo drives in precision applications. They control motors with feedback mechanisms. These drives typically feature high torque and speed levels. Their precision makes them useful in robotics and automation systems.

A friction variable frequency drive consists of an electric motor and a cone clutch. It utilizes friction to control the electrical motor's speed and, consequently, the speed of the connected system. These drives are effective in power transmission. They control the motor speed without significant wear. These drives are typical in machinery with variable loads.

A 200 kW VFD offers many benefits in diverse industrial situations. Here are examples.

The oil and gas sector typically applies these drives in gas compression and pumping systems. The VFDs enhance operational efficiency in these contexts. They also reduce energy costs and maintenance needs.

Users deploy 200 kW VFDs in the mining industry to control the speed of heavy motors. They operate critical equipment like conveyors and pumps. These drives ensure precise motor control in this dynamic application. They enhance safety and reliability in the user's severe working conditions.

These drives apply to various metalworking equipment. For instance, users apply them in machining tools and metal extruders. Thus, they offer precise speed control and result in better product quality. They reduce energy consumption and increase process effectiveness.

Users apply these VFDs in their chemical processing plants. They manage the motors driving mixers, agitators, and pumps. These drives ensure that chemical reactions occur at the right speed and consistency. Thus, users achieve high-quality chemical products. They also reduce energy costs and enhance safety.

The water treatment sector employs these drives for pumps and compressors. They improve energy efficiency and reduce the wear rate on equipment. Thus, users enjoy lower operating costs. The drives offer precise control over water flow and pressure in treatment systems. This control ensures reliable operations and consistent results.

The cost of VFDs varies depending on several elements. The features enhance drive functionality and impact costs. Here are the factors.

The VFD type influences its price significantly. For instance, servo drives have complex control systems. This complexity results in higher costs. On the other hand, static drives are less expensive than VFDs. This difference is because static drives have simpler motor control mechanisms than servo drives.

Incompatible loads result in increased prices. Ideally, these drives need to be compatible with the motors they control. However, if a drive is incompatible with a motor, it results in additional costs for adapters. These expenses can accumulate quickly, resulting in a noticeable cost difference.

Advanced drives like those with energy-saving capabilities or built-in filters are more expensive. Drives with communication interfaces have increased costs, as do those with integrated safety features. Some might include automatic energy-saving systems and regeneration capabilities.

Since renowned brands invest in research and development, their VFDs might have advanced features. These features enhance efficiency and reliability. Although users can find cheaper alternatives with the same specifications, they might not have the same product quality. Therefore, this difference tends to result in a noticeable price variation.

Business owners should consider the following when purchasing varibale-frequency devices.

Buyers should ensure the VFD can adequately control the motors in their systems. If the motor is bigger than the device, the drive will underperform. Yet, if it's larger than the motor, it might consume more energy than required.

If clients operate the VFDs in harsh conditions, they should purchase ones with additional protective features. These extra features include protective enclosures. Also, select the right VFD according to the working temperature range.

VFDs employ different control techniques. For instance, AC vector control offers high torque at varying speeds. This feature is excellent for precision tasks. On the other hand, VFDs with PWM are easy to handle. They provide a steady voltage supply.

VFDs are designed to run on different power supply systems. The systems include single-phase and three-phase power supplies. Other than the phase type, they also feature diverse voltage ratings. Therefore, buyers should get VFDs compatible with the power supply of their clients' operations.

Horizontal pumps do not need a quick response to changes in the operating conditions. Therefore, businesses can use simple VFDs for this application. Yet, complex applications like compressors require advanced features for precise control. These features enhance system reliability. So, business owners should consider their clients' operational needs to help them get the right VFDs.

Although 200 kW VFDs have different features, here are some common ones to consider.

200 kW variable frequency devices usually have several key features. For instance, most VFDs come with a varying frequency range. It enables precise motor speed control. They also have built-in energy-saving features. This feature reduces power consumption and enhances operational efficiency. Their compact designs allow for easy installations in limited spaces. In addition, most VFDs come with protection classes. They safeguard the device against external factors like dust and moisture.

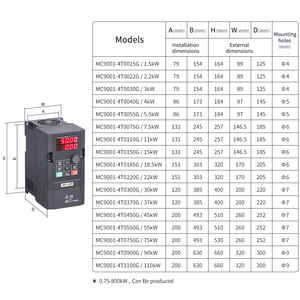

Common specifications to consider include power ratings, input voltages, and frequency ranges. These devices can handle significant power ratings as they control large motors. This feature makes them suitable for heavy industrial applications. Most of these devices operate on various input voltages. The voltages typically range from 400 to 800 volts. They accommodate different power supply systems. In addition, they feature extensive frequency ranges. Many users use these ranges to control motor speeds. Most models can adjust frequency from 0 to 70 Hertz.

A1. Yes, these VFDs can work in harsh environments. However, clients should ensure they invest in ones with additional protecting features.

A2. Yes, buyers can apply these VFDs in low-speed operations. Thanks to their precise control capabilities. They are especially useful in low-speed torque-sensitive applications.

A3. Operating 200 kW VFDs at high temperatures without proper cooling will reduce their lifespan. Therefore, buyers should ensure the drives have adequate cooling mechanisms.

A4. While 200 kW VFDs are designed for durability, regular maintenance will ensure their optimal performance.

A5. The main causes include electrical surges, overheating, and moisture ingress.