Types of Vertical Parking Garages

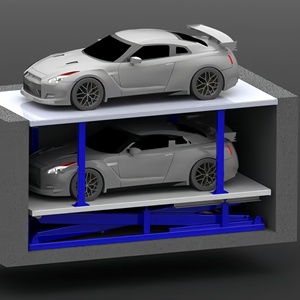

A vertical parking garage is an innovative solution that utilizes vertical space to park more vehicles than a traditional parking lot. Cars are automatically or manually transported and arranged in vertical columns using specialized equipment, maximizing space efficiency particularly in urban areas with limited land availability.

Automated Parking Garages

These systems use mechanical systems and computerized controls to park and retrieve cars with minimal human interaction. When a vehicle enters, the system automatically moves it to an available parking space.

- Parking Lifts: Raise and lower cars between different levels (2-6+ levels)

- Shuttle Systems: Transport cars horizontally and vertically for efficient movement in large facilities

- Rotating Towers: Feature revolving structures that turn to access different parking spaces

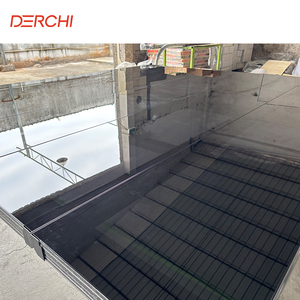

Stacker Parking Systems

An efficient solution for urban areas with limited space, stacker systems arrange multiple parking slots in vertical stacks with lifts for car movement.

- Two-Tier: Features two parking levels, one above the other

- Multi-Tier: Incorporates several tiers with more than two parking levels

Hybrid Parking Garages

These innovative systems combine vertical and horizontal parking designs. Some areas maximize space through vertical parking while others utilize horizontal layouts for improved accessibility and convenience.

Conventional Parking Garages

These structures feature ramps and aisles for parking cars across multiple levels. They can be constructed underground or above ground, with traditional horizontal parking layouts on each vertical level.

| Type | Space Efficiency | Automation Level | Best For | Installation Complexity |

|---|---|---|---|---|

| Automated Parking | Excellent | High | Urban centers, luxury developments | Complex |

| Stacker Systems | Very Good | Medium | Small to medium businesses | Moderate |

| Hybrid Garages | Good | Medium to High | Mixed-use developments | Moderate to Complex |

| Conventional | Fair | Low | Shopping centers, airports | Standard |

Expert Tip: When considering a vertical parking solution, evaluate your specific needs for automation, space efficiency, and budget. Automated systems offer the greatest space efficiency but at higher costs, while stacker systems provide an excellent middle-ground option for many applications.

Specifications and Maintenance

Key Specifications

Space Capacity

The total number of vehicles that can be accommodated within the system. This varies significantly based on the garage type and design.

Height Clearance

The vertical distance available for each vehicle. Typically ranges from 5-7 feet depending on the system and whether it accommodates SUVs/trucks.

Load Capacity

The maximum weight supported by the system, including vehicles and additional cargo. Most systems support 2,000-6,000 lbs per parking space.

Footprint

The overall dimensions (width and depth) of the parking system. A key advantage of vertical systems is their reduced footprint compared to conventional parking.

Power Consumption

Energy required for operating lifts, conveyors, and control systems. Modern systems are increasingly energy-efficient with power-saving features.

Safety Features

Includes emergency stops, fire suppression systems, safety barriers, and sensors to protect both vehicles and users.

Customization Options

Adjustable parking spaces, lighting, signage enhancements, and aesthetic considerations to match specific requirements.

Accessibility

Considerations for pedestrian access, emergency services, and overall system usability, including ADA compliance where applicable.

Maintenance Requirements

Regular Inspections

Scheduled weekly, monthly, or quarterly inspections are essential to identify and rectify potential issues before they escalate into major problems.

Cleaning and Lubrication

Regular cleaning removes dirt and debris from critical components. Proper lubrication of moving parts minimizes friction, reduces wear, and extends system lifespan.

Component Replacement

Timely replacement of worn parts prevents system failures and cascade damage to other components. Follow manufacturer guidelines for replacement intervals.

Electrical System Maintenance

Regular inspection of wiring, switches, and control systems ensures safe and reliable operation. This is particularly critical for automated systems.

Load Management

Distribute loads evenly across the system to prevent excessive stress on components and ensure stable operation within specified weight limits.

Training and Safety Procedures

Personnel should receive comprehensive training on safety procedures, emergency response protocols, and proper equipment operation.

Important: Neglecting regular maintenance can lead to system failures, safety hazards, and costly repairs. Always follow the manufacturer's maintenance schedule and keep detailed maintenance logs for warranty purposes.

How to Choose Vertical Parking Garages

Selecting the right vertical parking system requires careful consideration of several factors to ensure it meets your specific needs. Always consider the end users and their requirements when making this significant investment.

Space Availability

Assess your location's dimensions and layout to determine if there's adequate room for the system, including entry/exit paths and clearance requirements.

Key consideration: Both horizontal footprint and vertical clearance

Capacity Requirements

Determine how many vehicles need accommodation based on average daily traffic, peak demand periods, and anticipated future growth.

Planning tip: Add 15-20% capacity beyond current needs

Vehicle Size and Type

Consider the typical vehicles that will use the system. If larger vehicles like SUVs or trucks are common, select a system designed to accommodate various vehicle dimensions.

Standard dimensions: Height 5'-7', Width 6'-8.5', Length 14'-18'

Safety and Security

Prioritize systems with comprehensive safety features including fire protection, emergency exits, structural integrity, surveillance, and access controls.

Must-have: Emergency power backup systems

System Efficiency

Evaluate the speed of parking/retrieval operations, energy efficiency, and overall footprint to maximize space utilization while minimizing wait times.

Speed benchmark: Retrieval times under 2 minutes

Installation and Maintenance

Consider the complexity of installation, ongoing maintenance requirements, and availability of service technicians in your area.

Long-term planning: Factor in 10+ year maintenance costs

Cost Considerations

Evaluate both initial installation costs and long-term operational expenses including energy consumption, maintenance, and potential part replacements.

ROI calculation: Compare to land costs in your area

| Factor | Automated Systems | Stacker Systems | Conventional Garages |

|---|---|---|---|

| Initial Cost | High | Medium | Medium-High |

| Space Efficiency | Excellent | Very Good | Good |

| Retrieval Speed | Variable (1-3 min) | Fast (30-60 sec) | User-dependent |

| Maintenance | Complex | Moderate | Simple |

| Expandability | Limited | Moderate | Difficult |

Expert Recommendation: For most commercial applications, semi-automated stacker systems offer the best balance of cost, space efficiency, and ease of maintenance. Fully automated systems are ideal for premium developments where space is at an absolute premium and higher costs can be justified.

DIY and Replacement Guide for Vertical Parking Garages

While vertical parking systems are complex, many maintenance and replacement tasks can be performed without specialized assistance if you follow proper procedures and safety protocols.

Safety Warning: Always disconnect power before performing any maintenance or replacement tasks. Wear appropriate safety gear and never work alone when dealing with heavy components or electrical systems.

Component Replacement Guidelines

Before beginning any replacement:

- Consult the manufacturer's manual specific to your model

- Gather all necessary tools and replacement parts

- Secure the work area and place warning signs

- Disconnect power to the system component

When removing damaged components:

- Use appropriate tools to avoid damaging surrounding parts

- Label all connections and take photos for reference

- Place removed parts in a designated area away from the work zone

- Clean the mounting area thoroughly before installation

When installing new parts:

- Verify the replacement part matches specifications exactly

- Follow torque specifications for all fasteners

- Reconnect wiring according to your documentation

- Apply proper lubrication where specified

After installation:

- Perform a visual inspection before reconnecting power

- Test the component at low load initially if possible

- Monitor for unusual noises, vibrations, or movements

- Document the replacement in your maintenance log

Commonly Replaceable Components

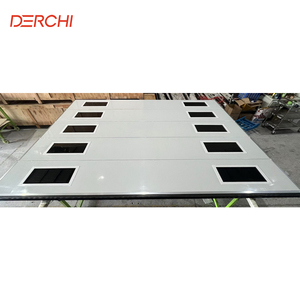

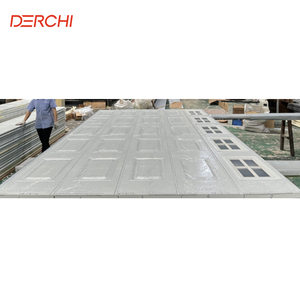

Doors

Entry/exit doors can be replaced by following manufacturer guidelines. Most systems use standardized doors that can be unbolted and replaced with basic tools.

Difficulty: Low to Medium

Parking Lift Motors

Motors that have reached end-of-life can be replaced by disconnecting power, removing mounting bolts, disconnecting wiring, and installing the new unit in reverse order.

Difficulty: Medium to High

Parking Guides

Guides help position vehicles correctly and can be installed by screwing them into designated mounting points on the floor or walls of the system.

Difficulty: Low

Control Units

Modern parking systems use electronic control units that can be replaced by carefully disconnecting all wiring (after labeling), removing mounting hardware, and installing the new unit.

Difficulty: Medium

Maintenance Tip: Create a detailed maintenance schedule and keep records of all replacements, including part numbers, dates, and any adjustments made. This documentation is invaluable for troubleshooting and warranty claims.

Frequently Asked Questions

Vertical parking garages are designed to maximize space efficiency, requiring significantly less area than conventional parking structures. Typically, an automated vertical system can accommodate 2-3 times more vehicles in the same footprint as a traditional garage. The exact space requirements depend on:

- System type and design (fully automated systems are most space-efficient)

- Number of vehicles to be accommodated

- Vehicle size requirements (larger vehicles need more space)

- Entry/exit configuration

For example, a 10-car stacker system might require as little as 1,200-1,800 sq ft, compared to 3,000-4,000 sq ft for conventional parking.

The cost of vertical parking garages varies widely based on several factors:

- System Type: Fully automated systems typically cost $15,000-$25,000 per parking space

- Basic Stackers: $6,000-$12,000 per parking space

- Capacity: Larger systems often have lower per-space costs due to economies of scale

- Location: Installation costs vary by region and local labor rates

- Customization: Special features and finishes add to the cost

While the initial investment is higher than traditional parking, vertical systems often provide better long-term ROI through space savings, particularly in high-value real estate areas.

Yes, modern vertical parking garages are designed with multiple safety systems:

- Structural Safety: Engineered to meet or exceed building codes

- Fire Protection: Fire detection and suppression systems

- Operational Safety: Sensors prevent movement when people are detected

- Power Backup: Emergency systems ensure vehicles can be retrieved during outages

- Security: Controlled access reduces theft and vandalism risk

In many ways, vertical parking systems are safer than conventional garages as they eliminate human driving errors within the structure and reduce pedestrian-vehicle interactions.

Yes, many modern vertical parking systems can be equipped with EV charging capabilities. Implementation approaches include:

- Dedicated EV spaces with permanent chargers

- Automated charging systems that connect when the vehicle is parked

- Battery swap stations for compatible vehicles

When planning a new vertical parking garage, it's advisable to include EV charging infrastructure from the beginning, even if current demand is low, as retrofitting can be more expensive.

Vertical parking systems can accommodate most standard vehicles, but there are limitations:

- Standard Systems: Most handle vehicles up to 6,000-7,000 lbs, 6-7 ft height, and 17-18 ft length

- Specialized Systems: Available for larger vehicles but at higher cost

- Vehicle Types: Accommodates most cars, SUVs, and small trucks

- Alternative Uses: Some systems can be configured for motorcycles, bicycles, or specialized equipment

Before selecting a system, analyze your vehicle demographic to ensure compatibility with the majority of vehicles that will use the facility.