All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1542 products available)

Market Overview: The global linear guide rail market, which includes the V groove rail segment, has shown promising growth, expanding from approximately USD 391.13 million in 2023 to USD 419.14 million in 2024. This growth trajectory is expected to continue, with a projected compound annual growth rate (CAGR) of 7.67%, reaching around USD 656.24 million by 2030, according to Research and Markets. The increasing demand for precision machinery in sectors such as manufacturing and automation is a significant driver for the V groove rail market. The Americas region, particularly the United States, is leading this growth, fueled by advancements in manufacturing automation and robust investments in infrastructure. Meanwhile, the Asia-Pacific region, dominated by China, is experiencing the fastest growth due to its expanding manufacturing capabilities and low production costs.

Industry Insights: The V groove rail market is characterized by its critical role in high-precision applications, including CNC machining and robotics. As industries increasingly adopt automation, the demand for reliable and efficient motion control systems has surged. However, challenges such as high initial costs and the necessity for regular maintenance may hinder potential users. Moreover, the introduction of innovative materials and technologies, such as corrosion-resistant and self-lubricating features, presents opportunities for growth. Companies are also addressing customer pain points related to installation complexities and maintenance costs, which could enhance market penetration. As the V groove rail continues to evolve, its integration into niche markets like optical and medical equipment will further solidify its importance in the industrial machinery landscape.

V groove rails are available in many types to suit different machinery applications. Here are some of the most common types of V groove rails:

V Groove Steel Rail

The steel rail is a guide used in various machinery applications. It is commonly used in heavy-duty machinery for its strength and durability. Usually, steel rails are made from high-quality carbon steel materials to withstand more constant and weighted movements.

V Groove Stainless Steel Rail

The stainless steel rail is a rust-resistant guide used in different environments. It is often used in high-moisture, chemical, or cleanroom applications for its corrosion resistance. Stainless steel V groove rails can last for many years because they don't rust and require little to no maintenance to stay functional.

Aluminum V Groove Rail

The aluminum rail is a lightweight guide used in portable or lightweight assemblies. It is frequently used in benchtop, robotics, or home project applications where weight is a concern. Aluminum rails have many great features, including being easy to cut, lightweight, and simple to install. All these make them suitable for use in lightweight and small-scale applications.

V Groove T Slot Rail

The T-slot rail has a profile resembling the letter T. The T-slot design creates a groove for easy bearing attachment and allows for adjustable, modular assembly. The V groove T-slot rail is commonly used in modular build systems, automated machinery, and custom equipment design. This type of rail is compatible with various sliding elements and makes easy to prototyping and fabrication fast.

Mini V Groove Rail

The mini groove rail is a smaller guide that is used where space is limited. It is often used in compact assembly, precision instruments, or micro-scale devices. The mini V groove rails are available in different lengths and sizes to suit a wide range of applications. Some have a load capacity that is great enough to support most standard and heavier miniature components.

Structural Support in Machines and Equipment:

Mankind has used V groove brackets for structural support in machines and equipment for many years. Whether they're large industrial machines or small kitchen appliances, these brackets are reliable and strong. For example, they might hold up an electric motor in a big factory cutting tool or keep a heavy compressor firmly attached inside a refrigerator. Because of their strength and stability, V groove brackets provide lasting support.

CCTV Camera Mounts:

V groove brackets work well as CCTV camera mounts. CCTV cameras can be heavy when they have to cover a large area. V groove brackets hold these cameras tightly so they won’t move or fall. They can support different weights of cameras, whether small or big. V groove brackets also have a benefit that matters very much for CCTV - they allow the camera angle to pan. The camera can swivel left and right smoothly and easily if the mounting is attached with a V groove bracket. This is called adjusting to get the proper field of view. With proper field of view adjustments, more details can be captured. V groove CCTV mounts are used both indoors and outdoors.

Linear Motion in Industrial Machines:

V groove rails are frequently used in conjunction with linear motion systems. This is especially common in industrial machines and equipment. Heavy-duty linear motion requires strong components because industrial activity is involved. V groove rails provide the strength necessary. They offer durability and smooth linear motion. This allows for precise and reliable heavy-duty linear movement operations in an industrial machine setting.

Transport and Conveyor Systems:

V groove rails play a crucial part in the function of many transportation and conveying systems. V groove guides, which are composed of V groove rails, assist in directing things as they are moved or delivered throughout a system. For example, merchandise may be moved throughout a factory utilizing a conveying system composed of V groove rails to assist in routing the products as they travel the conveyer. Conveying systems are also frequently constructed to be supported by V groove brackets. To put it another way, V groove rail guides and brackets are essential parts that frequently support and lead items in a wide range of transportation and conveying systems. For instance, they can be utilized on a material handling conveyor or an assembly line conveyor.

Application Requirements:

Business buyers need to consider the specific application requirements to choose suitable V groove linear rails. They should think about factors such as load capacity, travel distance, speed, and working environment. For instance, if they are working with heavy loads or high weights, they may need to choose those with larger rail sizes that can support the weight.

Compatibility with Other Components:

Business buyers need to consider the compatibility of V groove rails with other system components, such as motors, drives, and controllers. They need to ensure that the linear rails they choose can work seamlessly with existing system components to avoid potential integration issues and ensure smooth system operation.

Quality and Supplier:

It is vital for business buyers to choose high-quality V groove rails to ensure system stability and durability. They need to research the suppliers carefully, check their product certifications and reputation, and consider their after-sales support and service.

Cost-effectiveness:

Business buyers need to consider the cost-effectiveness of the linear rail systems. They should evaluate the performance, quality, and durability of the rails to ensure that the selected ones can meet business needs at an appropriate budget.

Q1: What are V-track rollers?

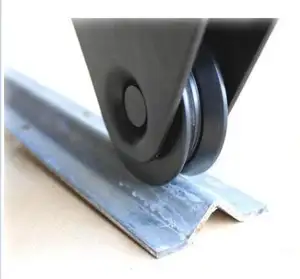

A1: V-track rollers are used to support or guide moving elements along V-groove rails. They are components of linear motion systems that enable sliding actions when mounted on a track.

Q2: What are the differences between V rails and other types of rails?

A2: V rails have a geometry that resembles a V with the same characteristics as other groove rails. Other types of rails include square and round rails. V-groove rails provide better self-aligning properties compared to square and round rails.

Q3: Do V-groove rails have limitations?

A3: While V-groove rails are self-aligning and easy to install, they have load limitations. Heavy-load applications may require alternative linear motion solutions, such as using linear guide rails.

Q4: Are V-groove rails pre-cut in the kit?

A4: Some CNC machines are equipped with V-groove rail kits that include pre-cut V-groove rails. However, buying separate V-groove rails is still possible.

Q5: Can one manufacture V-groove rails in-house?

A5: Yes, as long as one has the right materials and equipment. However, it is usually cost-effective to buy V-groove rails in small quantities.