(1380 products available)

Concrete column formwork is a temporary structure used to mold concrete into required shapes and sizes. It's an essential tool in the construction industry as it helps create stable foundations for buildings and other structures. Formwork is usually removed once the concrete has cured and is stable enough to stand on its own. Various types of used concrete column formwork are as follows:

Traditional Timber Formwork

This type of formwork is made from timber, which is commonly known as stick formwork. It consists wooden boards used to create the column molds and timber props to support the structure. Traditional timber formwork is designed and constructed on-site. It's adjustable and can be used for different types of columns. This formwork is cost-effective for projects with a small scope. However, it's not commonly used due to its high labor intensity.

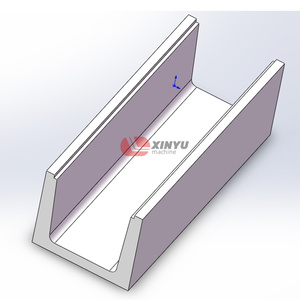

Metal Formwork

As the name suggests, metal formwork is made from metal materials, usually steel or aluminum. The formwork comes in various sizes and shapes to accommodate different concrete column designs. It has a smooth surface that enhances the quality of the finished concrete. Metal formwork is durable and can be used multiple times. However, it is more expensive than other types of formwork.

Engineered Formwork System

This formwork system is made from engineered materials such as steel and plywood. It's prefabricated in a factory and then assembled on-site. The engineered formwork system is designed to accommodate various shapes and sizes of concrete columns. It requires less labor to install and can be reused for multiple projects. However, this system requires a higher initial investment than traditional formwork.

Spiral Formwork

Spiral formwork is used for concrete columns that have a spiral shape. This includes bridges and architectural features. The formwork consists of a spiral metal or timber form with adjustable supports to hold it in place. Installing this formwork can be complex, but it produces concrete columns with a precise finish.

Fiberglass Formwork

Fiberglass reinforced plastic (FRP) formwork is an innovative technology used to form concrete beams and columns. The formwork is made from a composite material that consists of a polymer matrix reinforced with fiberglass strands. It is a lightweight, durable, and non-corrosive alternative to traditional timber or metal formwork. The surface of the fiberglass formwork is smooth, which helps improve the quality of the concrete finish. It also has a high degree of customization, allowing it to be molded into various shapes and sizes. This type of formwork is reusable and typically used in projects where weight and corrosion resistance are critical factors.

Concrete column formwork serves different functions and comes with various features. Here are some of them:

Support Concrete during Pouring

The concrete column formwork is vital in supporting and holding liquid concrete during the pouring process. It ensures the concrete structure is stable until it hardens and attains its strength.

Shape and Size

Column formwork determines the shape and size of the concrete column. It ensures the column is built to the specific design, size, and shape required by the engineers or architects.

Material

The concrete column formwork is made from various materials, such as steel, plywood, aluminum, and plastic. These materials can be easily assembled to create formworks of different shapes and sizes.

Reusability

Most column formworks are designed to be reusable. For instance, used concrete formwork is made for multiple uses, which helps to minimize construction costs. Its reusability is also environmentally friendly since it reduces the raw materials needed to construct new formworks.

Customizable

The concrete column formwork is highly customizable. It can be easily tailored to fit different column designs, sizes, and shapes. This adaptability ensures that it meets the unique needs of various construction projects.

Quality Finish

The formwork can provide a high-quality finish to the concrete surface. It ensures the concrete column has the desired texture and finish once the concrete cures.

Verticality and Alignment

The concrete column formwork ensures that concrete columns are straight, aligned, and vertical. It ensures the columns are built to the exact specifications and design required by the engineers or architects.

Used concrete column formwork has various applications in construction projects. Here are some common scenarios:

Reinforced Concrete Columns

Reinforced concrete columns support structures in building projects, parking lots, bridges, and other infrastructure. Used concrete column formwork is employed to mold columns around steel reinforcement bars (rebars) set in the ground.

Concrete Light Poles

Concrete light poles, also known as lighting columns or streetlight poles, are used to support outdoor lighting fixtures. They are made using used concrete column formwork to create tall and cylindrical structures that provide stability and durability.

Traffic Signal and Sign Support

Concrete columns are used to support traffic signals, stop signs, and other road signs. Their strength and resistance to wind and vehicle impact make them ideal for locations where they are permanently leaned or installed.

Utility Infrastructure

Utility infrastructure columns support overhead power lines, telecommunications cables, and other utilities infrastructure. They are made using used concrete column formwork to create stable, long-lasting, and weather-resistant columns.

Building Interior Columns

Interior columns made with used concrete column formwork are commonly used in large open spaces like warehouses, shopping malls, gymnasiums, and industrial facilities. They provide support without the need for load-bearing walls.

Parking Garage Support Columns

In parking garages, concrete columns support the structure's levels and vehicle loads. The columns are usually spaced out to allow for easy maneuvering of vehicles.

Bridge Piers

Piers are vertical structures that support bridges. They are made using second-hand concrete column formwork to create robust and resilient structures that withstand water flow, vehicle impact, and environmental elements.

Retaining Walls

Retaining walls are structures that hold back soil or water. Used concrete formwork can be adapted to create columns within retaining walls that enhance stability and load-carrying capacity.

When buying used concrete column formwork, several factors need to be considered to ensure the purchased formwork meets the requirements of future projects. These factors include:

Condition and Maintenance History

The formwork should be in a good condition with no visible damage, rust or warping. It's important to check the maintenance history to determine if it was properly maintained. Used formwork that was well maintained will be in a good condition and more suitable.

Type of Formwork

It's important to consider the types of formworks available, such as metal and concrete column formwork. Each type of formwork is suitable for specific project requirements. For instance, concrete column formwork is ideal for constructing columns, walls, and beams, while metal formwork is versatile and can be used for different structures.

Compatibility and Customization

The used column formwork should be compatible with the existing construction equipment. Used formwork that is compatible can be easily integrated into the construction process. Additionally, some used formwork can be customized to meet specific project needs. Therefore, it is important to consider the compatibility and customization options of the used formwork.

Load Capacity

When choosing used concrete column formwork, it is important to consider the load capacity. This is because not all formworks can support the same weight. Therefore, it is important to select a formwork that can support the weight of the wet concrete and any additional loads during the pouring and setting process.

Q1: How long can formwork be used for?

A1: Formwork can be used for a couple of months. However, it is important to note that the allowable formwork use period is dependent on various factors. These include the type of formwork, weather conditions, concrete mixture, and local construction regulations.

Q2: What is the maximum number of times concrete formwork can be reused?

A2: Used concrete column formwork can be reused several times, depending on the factors mentioned above. For example, steel formwork can be reused up to 200 times, while plywood formwork can be reused 15 to 25 times.

Q3: Can the concrete column formwork be adapted to different column sizes and shapes?

A3: Yes, adjustable column forms can be adapted to different column sizes and shapes. These include rectangular, square, and octagonal columns. This adaptability is one of the advantages of using formwork in construction.

Q4: What maintenance practices are required to keep the concrete formworks in good condition?

A4: Proper cleaning after each use, timely repairs of any damages, and proper storage when not in use are all part of the maintenance practices. It also includes applying release agents to prevent concrete adhesion.