All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1883 products available)

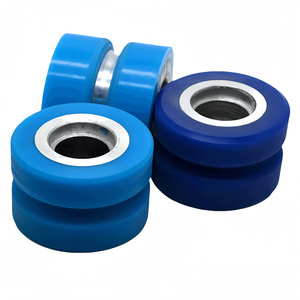

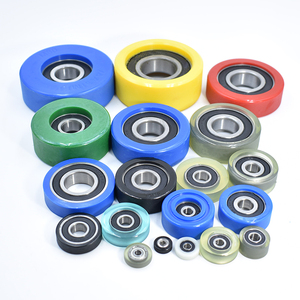

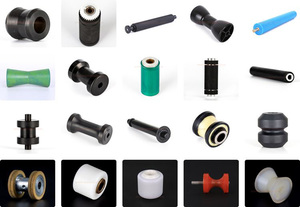

Urethane rollers have wide usage across several industrial applications due to their durability and resistance to abrasion, chemicals as well as temperature. The material is ideal for producing rollers in settings where there is repetitive motion or contact with heavy products. Furthermore, these rollers are often employed in production lines to aid product transfer while minimizing damage to the items being conveyed. In addition to this, they serve a vital role in printing processes by providing an even surface for ink application. They can also be utilized in general machinery as a protective component to reduce wear on sensitive parts of the systems. Below are some of the types available in the market.

The pressure sensitive urethane roller is frequently utilized in delicate product handling. This roller has the ability to adjust to surface variations on the items being transported because of its elastic properties. Furthermore, it evenly distributes pressure throughout its surface when in operation. As a result, this quality lessens the chance of harming fragile surfaces. Because of their versatility, these rollers find application in sectors like packaging, printing, and producing electronic components.

Urethane rollers that have been embossed are employed to generate patterns or designs on the surfaces of products. When printing or surface treatment, these rollers leave an impression on the item or substance being transported. Usually, these rollers are made to order depending on the required design. This specification allows the embossed urethane rollers to carry multiple print designs, ranging from straightforward geometric shapes to intricate designs. Also, these rollers are typically employed in industries that manufacture laminates, flooring, or other goods that require surface texturing.

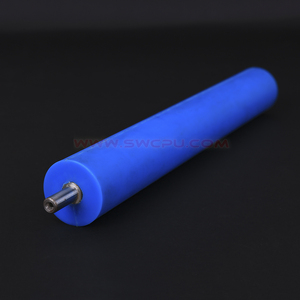

Urethane rollers with a flat design feature an even, smooth surface. These rollers are mostly used for tasks that require a precise, uniform application of force across an item’s surface. Industries such as woodworking, metalworking, and material fabrication make extensive use of flat rollers. Other industries that apply glue or adhesives during assembly processes also find them useful. In these sectors, the flat profile of the roller guarantees that adhesion is even and effective across the materials being processed.

Urethane rollers with a textured surface aid in gripping items or delivering materials with specific patterns imprinted on them. These rollers help raise surface friction because of their distinctive feel. This quality enables the proper transfer of materials in such production processes. In such processes, a precise connection between the roller and the material is fundamental to operation. Moreover, textured rollers are effective in a number of industries, including packaging, printing, and woodworking. They enhance both the performance and quality of the results in these industries.

Urethane rollers are widely used because of their resilience and versatility. Several industries benefit from their abrasion resistance, wear resistance, and ability to carry considerable loads. Their specific qualities make it possible for them to solve various issues of each industry. Below are the different industrial applications of urethane rollers.

In the printing sector, urethane rollers are an important tool that helps with ink distribution and application. Their smooth, even surface assures consistent ink application to printed surfaces. This consistency is crucial for high-quality print results. Also, these rollers are resistant to chemical products, such as inks and solvents. This resistance keeps the rollers from becoming corroded over time, ensuring that the printing process remains efficient and reliable. Embossed and textured rollers also find application in this industry. These rollers are for applying particular patterns or textures to the materials being printed on.

The packaging industry has great reliance on urethane rollers to carry out smooth operation within their production lines. These rollers help in the conveyance of merchandise through different processing stages including filling, sealing, and labeling. Because of their adaptability, urethane rollers apply and evenly distribute adhesives in processes that require gluing, such as attaching labels or putting together boxes. The flat profile of the rollers guarantees that the glue or adhesive is evenly distributed across the packaging components. The result of this is that the integrity of the packaging is maintained and quality is enhanced.

Urethane rollers play an important function in the woodworking industry in procedures such as sanding, laminating, and coating. The rollers are applied to the laminate surfaces to ensure an even smooth finish before cutting the wood into its required sizes. The urethane’s softness compared to metal rollers enables them to adhere to any surface. This quality enables them to produce a smooth surface free of score marks on the wood. Their smooth nature allows them to evenly and cleanly transfer materials during this process.

Urethane rollers have a particularly important function in the industrial production of heavy-duty materials like tires, belts, and hoses due to their exceptional durability. These rollers withstand the forces involved in molding and shaping these large products. In addition, their abrasion-resistant surface guarantees that they retain their effectiveness throughout a long production cycle. This endurance is essential for maintaining the quality of the finished goods and preventing production disruptions.

A1: Urethane rollers see extensive application in such practices as machining, handling of materials, and coating. These processes require smooth and durable contact surfaces. The reason being, they protect the items being handled while providing a strong grip. Due to their strong surface quality, which resists abrasion as well as chemicals, they are ideal for usage across various industries. These industries include woodworking, printing, packaging, and manufacturing.

A2: Urethane rollers have greater durability and longer life compared to rubber rollers. This durability enables a reduction in production costs over a short period of time. Urethane rollers are also more resistant to chemicals and heat than rubber rollers. Moreover, urethane rollers are more adaptable to varying surface textures. That means they can be textured or engraved to produce different patterns. This feature further improves their grip and the quality of the finish in various operations. These characteristics make urethane rollers particularly advantageous in industrial applications associated with heavy loads and arduous working conditions.

A3: To increase the durability of urethane rollers, make a habit of cleaning them after each use. Doing this helps eliminate leftover residues that cause abrasion on the rollers. Also, avoid exposing the rollers to extreme temperatures. Such temperatures can either harden or degrade the material. In addition, always check to ensure that the rollers are properly aligned with the materials being conveyed. This action prevents uneven wear, mechanical failure, and safety hazards to employees. Finally, minimize the load carried by the rollers within their specified load capacities. Doing this will reduce stress on the material and help prevent early tearing.

A4: Various maintenance practices ensure that urethane rollers last longer and remain efficient. These practices include regular cleaning of the rollers, visual inspection, and lubrication of the shaft. Other maintenance activities involve proper storage and usage within load limits. These practices are simple but go a long way in ensuring that the rollers remain effective and safe to use for the given intended purpose.

A5: Consider the roller material and its durability, urethane’s quality, and whether it is compatible with the equipment of the industry. Also, consider what industry application the roller will be specifically used for. Other factors to consider include the roller's diameter, width, and durometer. These parameters will affect the overall performance of the roller in the industry.