Types of Underground Car Stackers

An underground car stacker is designed to increase parking capacity in areas with limited space. These innovative systems are commonly found in multi-story buildings, urban areas, or residential apartments where maximizing parking space is crucial. The mechanism to load and unload cars is engineered to be simple and user-friendly, making it accessible for everyday use.

Expert Tip: When considering an underground car stacker, evaluate not only your current parking needs but also future requirements. Many property owners find that investing in a system with slightly higher capacity than immediately needed provides valuable flexibility as vehicle sizes and parking demands change over time.

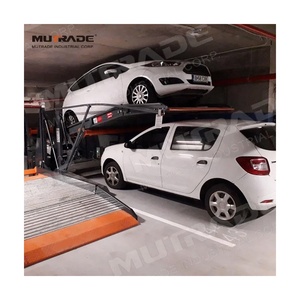

2 Post Car Lifts

These lifts are widely used in both residential and commercial parking lots due to their efficient design. They feature two vertical posts with parking platforms at the top and bottom, providing a simple yet effective lifting mechanism.

Best for: Standard-sized vehicles with normal height profiles

Limitations: May not accommodate oversized or exceptionally tall vehicles

4 Post Car Lifts

Four-post car lifts expand on the two-post design by adding two additional support posts. This enhanced structure provides greater stability and weight-bearing capacity, making it suitable for a wider range of vehicles.

Best for: All vehicle sizes including larger SUVs and heavier vehicles

Advantages: Superior stability, higher load capacity, accommodates wider vehicles

Rotary Car Lifts

Rotary car lifts incorporate an innovative rotating feature that maximizes space efficiency. Instead of lifting vehicles straight up, these systems rotate and lift them to one side, significantly reducing the space footprint required.

Best for: Extremely space-limited parking areas

Space efficiency: Requires up to 30% less space than conventional lifts

Scissor Car Lifts

Scissor car lifts utilize a mechanical system resembling scissors that expands when activated. This design allows the platforms to move apart while lifting the vehicle, creating a compact solution for space-conscious installations.

Best for: Underground parking with height restrictions

Key feature: Low profile design when collapsed, ideal for low-clearance environments

Platform Car Lifts

Platform car lifts feature expansive platforms capable of accommodating one or more vehicles depending on their size. These systems are perfect for commercial applications where maximizing parking capacity is a priority.

Best for: Commercial parking lots needing maximum capacity

Installation: Can be retrofitted into existing underground parking structures

| Stacker Type | Capacity | Space Efficiency | Installation Complexity | Best Application |

|---|---|---|---|---|

| 2 Post Car Lifts | Medium | Good | Moderate | Residential, small commercial |

| 4 Post Car Lifts | High | Moderate | Moderate to High | All-purpose, larger vehicles |

| Rotary Car Lifts | Medium | Excellent | High | Space-limited urban areas |

| Scissor Car Lifts | Medium to High | Very Good | Moderate | Low-clearance environments |

| Platform Car Lifts | Very High | Good | High | Commercial lots, multiple vehicles |

Specifications and Maintenance of Underground Car Stackers

Key Specifications

- Capacity: Maximum weight that can be lifted safely (typically 2,000-4,500 kg)

- Vehicle Dimensions: Maximum height, width, and length limits for compatible vehicles

- Clearance Height: Distance between platform and underground floor

- Lifting Speed: Time required to complete lift/lower operations

- Control Systems: Automatic, manual, or remote operation options

- Safety Features: Emergency stops, brakes, and load sensors

Essential Maintenance

- Regular Inspection: Visual checks before/after use to identify wear or damage

- Cleaning: Regular removal of dust and debris to maintain performance

- Lubrication: Periodic lubrication of moving parts to reduce friction

- Load Management: Ensuring weight limits are respected and loads are evenly distributed

- Operator Training: Proper training to ensure safe operation and prevent accidents

| Maintenance Task | Frequency | Importance | Professional Help Required |

|---|---|---|---|

| Visual inspection | Before and after each use | Critical | No |

| Hydraulic fluid check | Monthly | High | No |

| Lubrication of moving parts | Monthly | High | No |

| Electrical system inspection | Quarterly | High | Yes |

| Structural integrity check | Semi-annually | Critical | Yes |

| Complete system overhaul | Annually | Critical | Yes |

Maintenance Tip: Keep a detailed maintenance log for your underground car stacker. This documentation not only helps track maintenance schedules but also provides valuable information for technicians when servicing the system and can be essential for warranty claims.

How to Choose an Underground Car Stacker

Selecting the right underground car stacker requires careful consideration of several critical factors to ensure optimal performance, safety, and efficiency. Making an informed choice will result in a system that meets your specific needs and provides reliable service for years to come.

Primary Selection Factors

Load Capacity - Choose a stacker with at least 15-20% more capacity than your heaviest vehicle to ensure safety margins and accommodate future needs.

Clearance Height - Consider the height of your tallest vehicle plus additional clearance for antennas, roof racks, or other attachments.

Safety Features - Prioritize systems with comprehensive safety features including emergency stops, overload protection, and anti-fall mechanisms.

Secondary Considerations

Space Requirements - Evaluate the footprint needed for the stacker itself plus required access and maneuvering space.

Ease of Operation - Consider user-friendly controls that minimize training requirements and reduce operation errors.

Construction Quality - Assess material durability and component quality to ensure long-term reliability in underground conditions.

| Selection Factor | What to Consider | Common Mistakes to Avoid |

|---|---|---|

| Load Capacity | Total weight of vehicle including passengers, fuel, and cargo | Underestimating future vehicle weight or overlooking safety margins |

| Vehicle Dimensions | Maximum dimensions of all vehicles that will use the stacker | Measuring only the current vehicles without considering future replacements |

| Safety Features | Emergency stop mechanisms, overload protection, power failure safeguards | Prioritizing cost savings over essential safety features |

| Space Requirements | Total installation footprint including access paths and clearances | Focusing only on the stacker dimensions without considering operational space |

| Maintenance Accessibility | Ease of access for regular maintenance and servicing | Installing stackers in locations that make maintenance difficult or dangerous |

Important Consideration: Always verify that your chosen car stacker complies with local building codes and safety regulations. Many jurisdictions have specific requirements for underground parking systems, including fire safety measures, ventilation standards, and structural specifications.

How to DIY and Replace Underground Car Stacker

While professional installation is recommended for complete stacker systems, many maintenance and replacement tasks can be performed with proper knowledge and precautions. Always follow the manufacturer's specific instructions for your model, as the following provides only general guidance.

Safety Warning: Working with underground car stackers involves significant safety risks including crushing hazards, electrical dangers, and hydraulic pressure risks. If you lack proper training and equipment, consult professional technicians for all but the most basic maintenance tasks.

Step-by-Step Replacement Process

Disconnect all power sources to the car stacker before beginning work. Ensure the area is well-lit and ventilated. Use appropriate personal protective equipment including safety glasses, gloves, and steel-toed boots.

Use only manufacturer-approved parts that match the exact specifications of your stacker model. Using incompatible components can lead to system failure and safety hazards.

Document each step of disassembly with photographs. Label all cables, hoses, and connections before disconnecting. Store small parts in labeled containers to facilitate reassembly.

Clean all components and surrounding areas thoroughly before installing new parts. Use appropriate cleaners that won't damage hydraulic seals or electrical components.

Follow the manufacturer's torque specifications when tightening fasteners. Ensure all hydraulic connections are properly sealed and electrical connections are secure and protected.

Reassemble components in the reverse order of disassembly, referring to your documentation. Double-check all connections before restoring power.

Start with no-load testing to verify basic operation. Gradually increase load testing to confirm proper function under normal operating conditions.

Perform a complete safety check including emergency stop functionality, limit switches, and all safety interlocks before returning the system to service.

DIY Tip: Create a detailed maintenance log that records all replacements, repairs, and service dates. This documentation provides valuable history for troubleshooting and helps maintain warranty compliance. Include details such as part numbers, service procedures, and operational observations.

Frequently Asked Questions

Space requirements vary significantly depending on the stacker type and configuration. As a general guideline, most systems require:

- Minimum ceiling height: 3.2-4.5 meters (depending on vehicle height)

- Footprint area: 15-30 square meters per stacking unit

- Access clearance: At least 1-2 meters on sides for maintenance

For precise requirements, consult with a parking system specialist who can provide specifications based on your specific vehicle types and space constraints. Custom configurations can often be designed for challenging spaces.

When properly installed and maintained, underground car stackers offer excellent safety. Modern systems incorporate multiple safety features including:

- Emergency stop systems that immediately halt operations

- Overload protection sensors that prevent operation when weight limits are exceeded

- Anti-fall mechanisms and mechanical locks that secure platforms in case of power failure

- Audible and visual warning signals during operation

- Safety interlocks that prevent operation when users are in danger zones

To ensure ongoing safety, regular professional inspections and strict adherence to maintenance schedules are essential. Operator training is also critical, as improper use can override built-in safety features.

Not all vehicles are compatible with every car stacker system. Each stacker model has specific dimensional and weight limitations:

- Height restrictions: Typically 1.5-2.1 meters maximum vehicle height

- Width limitations: Usually 2.0-2.4 meters maximum vehicle width

- Length constraints: Generally 5.0-5.5 meters maximum vehicle length

- Weight capacity: Commonly 2,000-4,500 kg per platform

Vehicles with very low ground clearance, special modifications, or unusual dimensions may require specialized stacker systems. Always check your specific vehicles against the manufacturer's compatibility specifications before purchasing a stacker system.

Installation timeframes for underground car stackers vary considerably based on several factors:

- Small residential installations: 2-4 weeks

- Medium commercial systems: 1-3 months

- Large multi-level systems: 3-6 months or more

These timelines can be affected by site conditions, existing structure modifications, permitting requirements, and equipment availability. The installation process typically includes site preparation, foundation work, equipment assembly, electrical and hydraulic system installation, testing, and commissioning.

Working with experienced installers and thorough pre-planning can significantly reduce installation time and minimize disruption.