All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(3500 products available)

Twist drill bits DIN338 are manufactured in several types. Each type has a unique angle and purpose. The types are as follows:

Standard Twist Drill Bits

The standard ‘go-to’ drill bits are best used with soft and medium-density materials. These materials include woods and plastics. They have a point angle of 118 degrees. This angle provides a good balance between penetration and cutting efficiency.

High-Speed Steel (HSS) Twist Drill Bits

The HSS drill bits are made of steel. This material can withstand high temperatures. HSS drill bits are also suitable for drilling harder metals like steel alloys and stainless steel. It is because it maintains its sharpness even when it gets hot.

Cobalt Twist Drill Bits

The cobalt drill bits have a higher content of cobalt in their HSS material. It makes them extremely hard and wear-resistant. The drill bits can handle high temperatures without losing their cutting edge. They are ideal for drilling tough materials. These materials include hardened steel and titanium.

Jobber Twist Drill Bits

The jobber bits are the most common type of drill bit used in general applications. The bits are ideally suited for medium depths. They are also versatile enough to be used across a range of materials. These materials include metals, wood, and plastics.

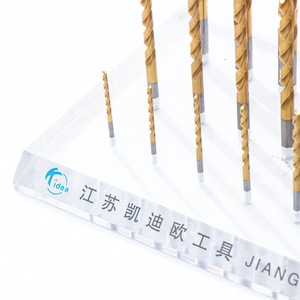

Extra-Long Twist Drill Bits

The extra-long drill bits have longer shanks and are suitable for drilling into deeper spaces. The bit length is around 2-3 times the standard jobber drill. They are excellent for drilling into hard-to-reach areas.

Fluted Twist Drill Bits

The fluted bits have spiral grooves along their length. The flutes help carry away chip debris from the hole being drilled. It also provides better lubrication. This bit is suitable for high-torque applications in hard materials.

Manufacturing

In the manufacturing sector, drill bits are used to create holes in metal parts. These parts include gears, shafts, and engine components. The bits are critical for machining processes like drilling, tapping, and reaming. Their precision ensures that manufactured parts meet stringent quality standards.

Construction

In the construction industry, drill bits help to create holes in concrete, metal reinforcements, and wood structures. The holes are for placing anchors, bolts, and screws. This makes the bits essential for structural integrity and safety in construction projects. The bits also aid in the installation of electrical systems and plumbing pipelines.

The bits also help when there is need to create in woodwork, metal frames, and other construction materials.

Automotive Industry

The automobile manufacturing and repair industries also use drill bits. They use them to create holes in engines, transmissions, and braking systems. The holes are then used for screws and bolts to assemble and maintain vehicles. This makes the bits vital for both vehicle production and repair work.

Aerospace

Come to think of it. In the aerospace industry, bits are ideal when precision drilling is paramount. No less because the aerospace bits are used on aircraft components including wings, fuselage, and engines. Those components are made from tough materials like titanium and aluminum. The bits are critical in ensuring safety and performance in the airtravel system.

Metalworking

Bits are staple equipment in metalworking. These holes are used to create complex designs and assemblies in metals. They are also essential in processes like drilling, tapping, and counterboring. No wonder quality bits have such a huge impact on the overall success of machining metal projects.

Tool and Die Making

The tool and die-making industry heavily relies on drill bits to create molds, dies, and tooling components. This is so whether for plastic injection, metal stamping, or other manufacturing processes. The precision and durability of the bits are crucial in producing high-quality tools that meet precise specifications.

Material Composition

Quality drill bits come with sturdy materials such as high-speed steel (HSS), cobalt, or carbide. These materials are significantly more resistant to wear, heat generation, and bending. This ensures that the bits stay sharper for longer. While on the other hand, soft metals dull quickly. The bits may also warp or break when under tough drilling conditions.

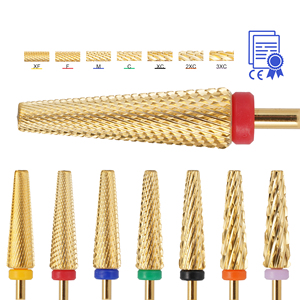

Coatings

What are coatings? Coatings like titanium, black oxide, and nitride were applied to the surface of the bits. They reduce friction during drilling. Less friction means less heat. Less heat, in turn, translates to less wear on the bits. The coatings also provide additional corrosion resistance. This extends the life of the bits in adverse environments. It is for instance when drilling into abrasive or acidic materials.

Geometrical Features

The design of the bit’s cutting edges and flutes also play a huge role in its durability. Bits with sharper cutting edges require less force to penetrate the material. This reduces the stress on the bit and minimizes chipping or cracking. Bits with well-designed flutes efficiently remove debris from the hole. Any accumulation of material can cause the bit to overheat. Overheating leads to excessive wear and potential breakage.

Heat Treatment

Bits that have undergone proper heat treatment have a harder surface. The heat treatment process creates a hardened edge that is tougher than the rest of the bit. Though the inner material retains some level of flexibility to absorb impact without fracturing. This helps that bits not get easily worn out and stay sharper for longer.

Shank Design

Straight shanks fit into drill chucks. Powerfully applied torque along the entire length of the bit. In other words, there’s no twisting or slipping as would be the case with a tapered shank. Any twisting would create micro-fractures at the junction. Not only does this reduce carrying capability. It can also lead to complete breakage if the bit becomes excessively worn and the connection is poor due to slippage.

Material

Drill bits come differently. Each type of metal has its own unique advantages. For instance, high-speed steel (HSS) is ideal for drilling soft and medium-hard metals like aluminum and brass. HSS bits maintain sharpness and are incredibly tough. They can take some serious beatings without bending or breaking. On the other hand, cobalt steel is harder than HSS. It retains its hardness even at extreme temperatures. This makes it ideal for drilling hard metals like stainless steel.

Coating

Don’t forget about the coating, would you? Bits boast of various coatings such as titanium, black oxide, and nitride. These coatings reduce friction and increase the bit’s resistance to wear. Titanium-coated bits have a longer lifespan. They’re great for general use. Black oxide bits, on the other hand, resist corrosion and can be used for longer in drilling applications that require less heat. Nevertheless, nitride bits stand out. They offer the hardest surface and can withstand the most extreme conditions.

Size

The standard sizes of these bits range from 1mm to 13mm diameter. The diameter ideally increases the drilling speed. It, however, lowers the drilling torque applied. Theough larger bits quickly make larger holes. More than that, they put more strain on the drilling equipment. Smaller bits do the opposite. They take longer to drill small holes, but they’re easier to handle. Go for variable-sized drill bits for general jobs. They’re versatile for light tasks.

Point Design

The point angle consists of the conical tip of the bit. It ranges between 90° and 140°. The larger the angle, the greater the force applied. This goes for the penetration combined with the spreading. Larger point angles are ideal for softer metals with a higher tensile strength. Such metals include stainless steel.

Brand Reputation

Researched, so that the brand offering the drill bit has a solid reputation can make a huge difference in quality. Therefore, the drill bits that users have a positive experience with can lead to greater customer satisfaction. User satisfaction guarantees a higher level of product performance and durability.

Definitely yes. Other materials like carbon steel, titanium drill bit set, and masonry drill bits are also used. Each of these bits comes with its own unique benefits for specific applications. Carbon steel bits are ideal for wood and plastic. They are less durable when compared to HSS bits. Anyway, they are great for softer materials. On the other hand, titanium and masonry bits are specifically designed for drilling into tough materials like concrete and masonry.

No, larger point angles don’t necessarily have to be better. Bits have larger point angles work well when drilling softer metals. Bits with smaller angles, on the other hand, are better suited for tougher materials. Users also prone to overheating should invest in bits with smaller point angles. Since they pose less risk of warping or damaging during the process.

No. Several brands with a high number of negative reviews can sometimes be manufacturers of quality products. Customer dissatisfaction often results from unrealistic expectations. It can also occur because the bits aren't ideal for the application they were designed for. As long as the reviews cite quality-related issues, then the brand's drill bits should be avoided at any cost.

Yes. Drilling into tough materials can cause a lot of wear on drill bits. It is therefore recommended, after every use, to clean and inspect the bits for damage. Follow up the inspection with a proper storage strategy. Also consider a regular sharpening schedule. All these go a long way in extending the life of the bits and optimizing their performance.