All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1334 products available)

Ready to Ship

Ready to Ship

Ready to Ship

Ready to Ship

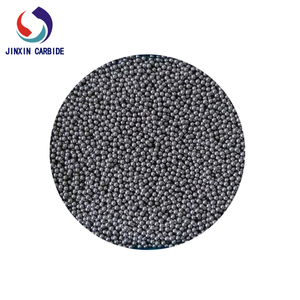

The tungsten carbide polished ball is a heavy and very dense ball used for different activities. It comes in different types based on various features and how they work.

These include the following:

Solid tungsten carbide balls

A solid tungsten carbide ball is a high-density, hard ball almost impossible to scratch. It looks very smooth and shiny because of its polished finish. Solid tungsten carbide balls are used in bearings, valves, and nozzles because they last long by resisting wear and tear especially in machinery operation.

Hollow tungsten carbide balls

Unlike the solid type, the hollow tungsten carbide ball has a channel running through its entire structure. This makes it much lighter and reduces the amount of raw material used in making it. Due to its lighter weight, it is suitable for applications like jewelry or in machinery where lower weights are preferred. Its strength and durability still make it a fitting candidate for applications that require heavy-duty materials.

Coated tungsten carbide balls

The original polished coating of the tungsten carbide ball can be enhanced with additional coatings. These are the type of coatings applied on the surfaces of metals for different characteristics such as a better resistance to corrosion and oxidation and a smoother than normal surface that reduces friction in metal contact. Examples of coatings are chrome, gold, or even titanium nitride. These are used for specific functional reasons or sometimes to improve the aesthetics of the ball.

Micro or mini tungsten carbide balls

These are the small-sized balls ranging from several millimeters to a fraction of millimeters in diameter. They have the usual polish and can be coated if necessary. Micro tungsten carbide balls are used in miniature bearings, medical devices, and precision machinery. These industries require very small components who need tight tolerances and durability to function correctly.

Ball blanks

Tungsten carbide ball blanks refer to the initial unpolished and uncoded shape of tungsten carbide balls. These are not the final products but the starting materials that will undergo further processes of polishing and possibly coating for achieving the desired characteristics requested by the client. These ball blanks are utilized by manufacturers who need to produce customized tungsten carbide balls to serve in various business spheres.

A tungsten carbide polished ball is very dense and heavy, and it doesn't break or get scratched easily. It looks smooth and shiny, and the design is very precise. Tungsten carbide balls come in various shapes, sizes, and designs depending on the features required and the use intended.

Spheres

The most common and typical shape of tungsten carbide balls is a sphere. This is the perfect geometric shape for spheres because they have identical points on the surface that are equidistant from the center. The tungsten carbide polished sphere bears very sleek and smooth and has the reflective properties associated with a highly polished surface. The spherical design allows for very uniform distribution of loads in mechanical applications, facilitating rolling motions without inducing undue stress on adjoining components.

Sizes

Tungsten carbide balls are produced in varied sizes, depending on their application. Diameter ranges are from a few millimeters to several inches. Miniatures are used in precision instruments and electronics. Larger ones are used in heavy machinery and industrial equipment.

Precision and tolerances

The polishing process of tungsten carbide balls creates extraordinarily accurate surfaces. The polished tungsten carbide ball may have a tolerance of ±0.001" or even tighter, depending on such factors as usage. Such precision is vital in applications like aerospace, firearms, and medical devices where there is no room for error due to extremely close fittings required and ensuring the correct functioning of these systems.

Smooth finish

The tungsten carbide ball is characterized by a very smooth and high-finish polish. This can only be achieved through advanced diamond polishing techniques. The application on the surface induces very low friction and resistance. A polished surface significantly reduces wear and tear on contact surfaces in rotating machinery. Examples are bearings or electro mechanical systems.

Internal structures

Most tungsten carbide balls have a solid internal structure. A few that require decreased weight or different density features may be designed with hollow or complex inner geometries. Such types are rare and mainly for specialized uses. Overall, the internal structure's consistent density provides exceptional hardness and durability.

Tungsten carbide balls are heavy and very hard. They are used in guns, machines, and hospitals. The polished finish makes them look smooth and shiny but strong. They come in various sizes, depending on the need, from tiny ones for small tools to large ones used in big factories. Tungsten carbide balls are used in many places because they last long and work well.

Aerospace industry

The aerospace industry uses tungsten carbide balls in its satellite, aircraft, and spacecraft. Their durability and resistance to high-power and force environments make them highly suitable for these applications. They are additionally used in ball bearings and other moving parts because of their exceptional hardness. These polished balls are critical in bearing the extreme heat, pressure, and friction encountered during flight and propulsion systems.

Firearms and military application

Tungsten carbide polished balls are used in ammunition in the military and firearms industry. Due to its density, hardness, and the ability to retain kinetic energy while traveling long distances, tungsten carbide makes an effective ballistic material. Polished balls are used in airsoft bbs, which are ideal for smooth feeding, better accuracy, and improved aerodynamic functionality. They reduce wear on firing mechanisms and increase the operational efficacy of military hardware in gun mechanisms and ammunition because polished surfaces create less friction.

Electronic devices and medical equipment

Apart from these applications, tungsten carbide polished balls are increasingly used in the medical and electronic industries. Because of the microsurgical instruments' wear and tear resistance, electronic components such as precision ball bearings incorporate them to improve smoothness and lifespan. For medical devices like infusion pumps used in health care, durable and reliable components are needed because lives depend on them. Polished tungsten carbide balls serve just that purpose.

Industrial machinery

In industrial machines, big tungsten carbide polished balls are used in ball bearings, valves, and other critical components. Industries use them in machinery to support enormous loads and combat wear in harsh surroundings like mines, and cement plants. In premium electro-mechanical systems where precision and strength are needed, the polished surface of tungsten carbide balls creates lower friction, increasing the effectiveness of these systems.

Specifications

Tungsten carbide polished balls have very specific traits. These balls are super dense, measuring over 15 grams per cubic centimeter. They are extremely hard, around 9 on the Mohs scale, so they won't scratch or wear down easily. Even at high temperatures, these balls are strong, and they can come in many sizes, ranging from tiny 1-millimeter spheres to large ones over 50 millimeters wide.

Maintenance guidelines

The following points must be taken into consideration:

Clean regularly

This can be done by soaking them in a gentle detergent solution and using a soft brush to scrub off any deposits.

Avoid harsh chemicals

Since these are polished finishes, avoid chemicals that can potentially change the surface finish. Tungsten carbide balls are very immune to most chemicals, but just standard care is taken for washing them.

Dry properly

After cleaning, air-dry or use a non-abrasive cloth to prevent moisture from causing tarnish or rust in coatings, if any.

Lubricate when necessary

Polished tungsten carbide balls don't generally need lubrication. However, if the application requires it, use a light machine oil. This prevents dust and other particles from accumulating and reduces friction, where applicable.

Store safely

Store in a cool, dry area. Keep it in a container that will protect it from environmental exposure and other elements that might cause damage or scratching.

Check for wear

Often, look for signs of abnormal wear or damage, especially if used in machinery or mechanical applications. If bearing of such components, for instance, has visible signs of damage like pitting or decreased functionality, then the ball may need to be replaced.

A1. Polished tungsten carbide balls are very hard and durable. They resist scratches and wear. They are used in industries like aerospace and medicine because they stay strong under tough conditions and their polished surface makes machinery work smoother without extra lubrication.

A2. Yes, they come in various sizes, from 1 millimeter to 50 millimeters, for requirements, whether small for precision tools or large for heavy industrial machines. Most are tailored to specific needs like aerospace or medical devices.

A3. Carefully wash them in gentle soap and water, avoiding harsh chemicals that could damage their surface. Afterward, dry them with a soft cloth to keep them clean and looking polished.

A4. Such balls are used in guns and aerospace for ammunition bbs. They are in the army because they are hard and heavy. They are also used in machines and medical devices like catheters because they last a long time and work well.

A5. Yes, coatings like titanium nitride give the balls extra protection from corrosion and wear. Gold and chrome coatings make them look better and improve their functionality for specific jobs.