Tungsten Carbide Pin Punch: An Overview

The tungsten carbide pin punch is an essential tool designed for precision work in various industries, from automotive to manufacturing. Engineered with durability and performance in mind, these punches are crafted from tungsten carbide, a material known for its exceptional hardness and resistance to wear. Ideal for driving pins, removing dowels, and aligning holes in metal workpieces, the tungsten carbide pin punch offers unmatched accuracy and efficacy.

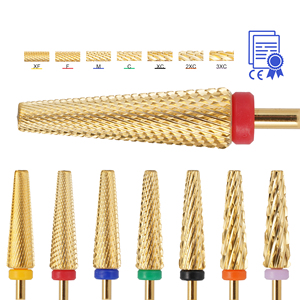

Types of Tungsten Carbide Pin Punches

When it comes to tungsten carbide pin punches, there are several types available to suit different applications:

- Standard Pin Punch: These are commonly used for removing and aligning pins in various materials.

- Tapered Pin Punch: Designed for precision tasks, these punches feature a tapered tip for easy insertion into tightly fitted pins.

- Flat Pin Punch: Ideal for surfaces requiring flat contact, they help in driving out pins without damage to the metal surface.

- Spring-loaded Pin Punch: This innovative design offers users enhanced control, allowing for one-handed operation through a spring-loaded mechanism.

Applications of Tungsten Carbide Pin Punches

Tungsten carbide pin punches are versatile tools applicable in various scenarios. Here are some common applications:

- Automotive Industry: Used for aligning and removing pins from engine components and other mechanical parts.

- Manufacturing: Perfect for precision work in assembly lines where pin alignment and removal are crucial.

- Tool and Die Making: Essential in creating and maintaining tooling for the production of metal parts.

- Jewelry Making: Helpful for intricate work in removing and resizing pins in jewelry repairs.

Features and Advantages of Tungsten Carbide Pin Punches

The tungsten carbide pin punch is equipped with several standout features that contribute to its popularity among professionals:

- Exceptional Hardness: Tungsten carbide is incredibly hard, making the punch more durable than traditional steel punches.

- Wear Resistance: The material is highly resistant to wear, ensuring longer tool life even in demanding applications.

- Precision Tip Design: The tips are designed to provide a precise fit for various pin sizes, minimizing the risk of damage to the punch or the pin.

- Corrosion Resistance: Tungsten carbide does not rust, making these punches ideal for use in various environments without compromising performance.

- Improved Impact Strength: These punches deliver superior impact strength, ensuring effective operation with less effort from the user.