(2328 products available)

Truck diagnostic scan tool helps access the truck's computer system, enabling the reading and clearing of diagnostic trouble codes (DTCs). They also provide real-time data on the truck's performance. There are several types of diagnostic scan tools for trucks, including:

Handheld Truck Diagnostic Scanner

These are small and portable diagnostic tools. Their size makes them easy to carry and use in different locations. Handheld diagnostic scanners for trucks are often battery-powered or have an internal battery. They are easy to use and often have user-friendly interfaces. They are also affordable compared to other diagnostic tools. However, they have limited functionality and diagnostic depth.

Bluetooth Truck Diagnostic Tool

These are diagnostic tools that connect to a truck's OBD-II port. They use Bluetooth technology to wirelessly connect to a smartphone or tablet. As a result, users can perform diagnostics using a mobile app interface. They are also convenient and portable due to their wireless connection. Bluetooth diagnostic tools are affordable and have customizable software. However, they have limited range and bandwidth. They also require a compatible device and may interfere with other wireless signals.

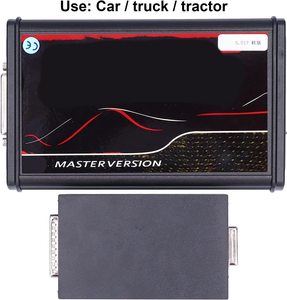

Professional Truck Diagnostic Scanner

These are advanced and comprehensive diagnostic tools. They provide deep-level diagnostics and access to various truck systems. Professional diagnostic scanners have extensive vehicle coverage. They also have advanced diagnostic functions, including programming and coding. They have user-friendly interfaces and are portable.

Some of the features of the professional truck diagnostic scanner are that they are expensive compared to other scanners. They also require regular updates to maintain compatibility with new vehicles. Additionally, they may require training or expertise to use effectively.

Multifunctional Truck Diagnostic Tool

These are diagnostic tools that combine multiple functions into a single device. They offer diagnostics, programming, and coding capabilities. Multifunctional tools also include live data streaming, actuator testing, and module programming. They provide comprehensive vehicle diagnostics and maintenance solutions. This feature makes them convenient and cost-effective since users don't have to purchase separate tools.

OEM-Specific Truck Diagnostic Tool

These tools are designed and developed for specific trucks by the original equipment manufacturer (OEM). They provide full access to the vehicle's integrated diagnostics and data. They also perform advanced functions, including coding, programming, and configuration of specific modules. However, they are more expensive than generic tools. They also require regular updates and are often limited to one vehicle brand.

Modular Truck Diagnostic Tool

These are diagnostic tools that have a modular design. They enable customize the diagnostic capabilities according to specific needs. Modular diagnostic tools for trucks include various modules or adapters. These are used to connect to different vehicle systems and protocols. They also allow for scalability and expand the diagnostic capabilities by adding more modules.

Modular diagnostic tools can be more expensive and require additional training or expertise to use effectively.

Below are the specifications and maintenance tips for heavy-duty truck diagnostic tools.

Specification

Every tool has a particular specification that makes it unique and suitable for particular purposes. Here is the specification of truck diagnostic tools.

1. Software: The scan tool contains specialized software that enables it to communicate with the truck's control modules. This software is regularly updated to cover new models and troubleshoot more effectively. Besides, it has a user-friendly interface that makes the navigation process easy for the users.

2. Hardware: It has a sturdy construction that enables it to withstand harsh workshop environments. The screen size varies from one diagnostic tool to another, with some having touch screen capabilities. Also, it contains a rechargeable battery that allows the tool to be portable.

3. Communication Protocols: The tool supports various communication protocols, such as Controller Area Network (CAN), Serial Communication Interface (SCI), and others. These protocols enable the tool to connect with different trucks' control modules.

4. Data Access: The diagnostic scan tool accesses live data, including sensor data, parameters, and vehicle statistics. The data enables the mechanic to make informed decisions during the vehicle's diagnosis. Besides, it has data logging capabilities that allow the mechanic to track the vehicle's performance over time.

5. Multifunctional Features: Truck diagnostic tools come with a variety of features, including reading DTCs, running live data, performing actuator tests, programming keys, and updating software. Some even have advanced features like coding and adaptation.

Maintenance

1. Cleaning: It is important to clean the diagnostic tool regularly to enhance its performance. Use a soft, damp cloth to clean the diagnostic tool's housing and screen. Also, use a soft brush to remove any dirt or debris from the connectors and ports.

2. Software Updates: Keep track of the software updates for the diagnostic tool. The updates normally enhance performance, add new features, and fix any bugs that may be in the previous version.

3. Battery Maintenance: Proper battery maintenance is essential for the proper functioning of the truck diagnostic tool. Always charge the tool's battery as instructed by the manufacturer. Also, replace the battery when it starts to lose its ability to hold a charge.

4. Connector and Cable Inspection: Inspect all connectors and cables for wear and damage. Replace them immediately if they show any sign of damage.

5. Storage: Store the tool in a clean, dry place when not in use. Keep it away from extreme temperatures and moisture, which can affect its performance. Also, keep it in its case to protect it from physical damage.

With so many options available, choosing the right tool can be challenging. Here are some tips:

Vehicle Coverage:

Consider the types and brands of trucks that the diagnostic tool can support. Choose a tool that can communicate seamlessly with the truck's control systems.

Functionality:

Different diagnostic tools offer various levels of functionality. Some provide basic code reading and clearing, while others offer advanced features like live data, actuator tests, and programming. Consider the required functionality and choose a tool that meets those needs.

Portability:

Consider whether a handheld, tablet-based, or laptop-based tool is needed. Handheld tools are portable and suitable for on-the-go diagnostics, while tablet or laptop-based tools offer a larger display and advanced functionality.

Update and Support:

Check if the manufacturer offers regular software updates to keep up with the latest vehicle models and technologies. Additionally, ensure there is reliable customer support for troubleshooting and assistance.

Budget:

Set a budget for the diagnostic tool. Consider the long-term benefits and cost savings of investing in a quality tool with the required features and functionality.

Reviews and Recommendations:

Research online reviews and seek recommendations from trusted mechanics, professionals, or peers in the industry. Their experiences can provide valuable insights into the reliability and performance of different diagnostic tools.

Maintaining and using the right tools trucks can help avoid delays caused by breakdowns and ensure that maintenance jobs are carried out effectively. The following are some important tips for selecting the ideal truck diagnostic scan tool for DIY:

Check the coverage range

Ensure the scan tool can access the car's systems, including the engine, transmission, ABS, and SRS. DIYers will require a tool with extensive coverage to diagnose and fix problems effectively.

Real-time data and live diagnostics

Accessing live data streams and monitoring real-time parameters from the car's sensors and systems may help identify problems and track performance in real time.

Ease of use and DIY-friendly design

Consider a user-friendly interface, clear instructions, and diagnostic functions, and avoid tools designed for professional mechanics with complex features and limited explanations.

Update and ongoing support

Choose a tool with reliable update options and ongoing support to stay current with automotive technology and diagnose emerging problems.

Q1: How often should one perform a diagnostic scan on a truck?

A1: There is no specific frequency for performing diagnostic scans on trucks. However, it is advisable to do so regularly, especially when the check engine light is on or before long trips, to ensure the vehicle is in good condition.

Q2: Can DIY truck diagnostic tools give as accurate results as professional ones?

A2: DIY tools can provide accurate results but not as detailed as professional tools. Professional tools have advanced features and are more precise.

Q3: What should a truck owner do if a diagnostic scan tool indicates an error code?

A3: The truck owner should investigate the meaning of the error code, which is usually in the tool's manual. If they can troubleshoot the problem, they should seek a professional mechanic's help.

Q4: Are truck diagnostic tools safe to use?

A4: Yes, diagnostic tools are safe to use. They are designed to be used by anyone, not just trained mechanics, and have safety measures.

Q5: Can these tools be used on all truck models?

A5: Not all diagnostic tools are compatible with every truck model. Buyers should ensure the tool is compatible with the truck's make and model.