All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(25411 products available)

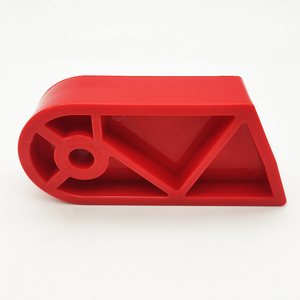

TPE (Thermoplastic Elastomer) is a rubber-like material that combines the durability and flexibility of elastomers with the processability of thermoplastics. It's widely used in various applications due to its adaptability and range of material properties.

Polymer blends and alloys

TPE plastic mould is often produced from selective blends of thermoplastics, such as polypropylene and polystyrene. These blends feature the toughness and structural stability of polyolefins and the elasticity and rigidity of styrenic thermoplastics, respectively. Such polymer blends can be optimized for a wide range of flow characteristics, stiffness, and temperature resistance to suit various moulding applications.

Thermoplastic polyolefins (TPO)

TPOs are fabricated from blends of polyolefins, like polyethylene and polypropylene, with elastomeric polymers. This TPE mould material combines the chemical and UV sterility of polyolefins with the elasticity of rubbery polymers. The alloying of these components yields a mould material that is highly resistant to environmental agents and suitable for automotive and outdoor uses.

Styrenic block copolymers (SBCs)

SBCs consist of recurring units of polystyrene and rubbery diene polymers. These copolymers can be thermally processed like plastics but exhibit elastic recovery akin to vulcanized rubbers. This unique combination emerges from the phase-separated microstructures formed by SBCs as they thermally cyclically process and mechanically stress these materials. These microstructures consist of rigid polystyrene domains embedded within a continuous diene rubber matrix. TPE plastic supply uses SBCs in moulds requiring flexibility and durability.

Acrylic modified thermoplastics

Acrylic-modified thermoplastics enhance the impact resistance and toughness of polycarbonate and other thermoplastics. Adding acrylic copolymers or resins provides TPEs with a degree of toughness and weather resistance not readily available in other thermoplastic alloys. This versatility and extend the operability of moulds subject to extreme environmental conditions.

Fillers and reinforcements

Adding filler materials like talc, mica, and carbon fibres improve the mechanical performance of TPEs. These adjuncts can enhance rigidity, inhibit thermal expansion, and extend service life. Filler incorporation may also modify the processing characteristics of these materials by affecting viscosity and flow behaviour during moulding. Common moulding techniques include injection moulding and blow moulding.

Consumer goods

TPE plastic moulds are widely used in manufacturing consumer goods. These moulds make items like toothbrush handles, phone cases, and kitchen utensils. These automobile parts have a smooth feel, are easy to grip, and are ergonomic. Moreover, TPE plastic mould is durable and resistant to chemicals. Therefore, it is ideal for daily use goods that must be comfortable and endure wear and tear.

Automotive components

In the automotive industry, TPE moulds construct seals, gaskets, and grips. These parts require flexibility, temperature tolerance, and resistance to automotive fluids. TPEs provide adequate sterility in automotive applications as they withstand extreme temperatures, chemicals, and UV radiation. Hence, the resulting parts maintain performance and reliability in harsh operating environments.

Medical devices

Furthermore, TPE moulds are used to construct medical equipment, including syringes, grips, and tubing. These Moulds comply with medical-grade regulations for sterility and safety. In addition, their easy recycling increases their sustainability credentials. Further still, their easy processing permits complex designs necessary for medical applications. These TPEs have low toxicity and are easily sterilized, making them suitable for implantable devices and other medical equipment that may come in contact with bodily fluids.

Flexible packaging

Moreover, TPE moulds are used to produce flexible packaging such as containers, bags, and wraps. The TPEs are lightweight, resilient, and transparent. They also have heat-seal capability, making them suitable for food and consumer product packaging. Further, these moulds offer barrier properties that protect contents from moisture and oxygen. This preservation maintains product freshness and extends shelf life.

Industrial equipment

TPE moulds manufacture grips, handles, and knobs in industrial settings. These components require comfort, ergonomics, and antislip properties. These TPEs are easy to clean, resistant to oils and greases, and durable, making them ideal for use in manufacturing and assembly areas.

Shore hardness

TPE moulds are customisable to varying degrees of shore hardness. Shore A ranges from a soft 10A for extreme pliability to a firm 90A for a stiff touch. Conversely, Shore D gauges measure for applications needing denser materials. This adaptability of hardness tunes the moulds for diverse end use requirements. These requirements may include overmoulding automotive parts to medical device housings, requiring precise grasping feel.

Thermal properties

TPE moulds can be designed to withstand a myriad of service temperatures. These moulds maintain integrity and flexibility in extreme heat or freezing conditions. Such a diverse thermal range allows one to extend applications for automotive parts in extreme climates, outdoor fixtures exposed to weather elements, and appliances functioning in high-temperature environments. Further still, the moulds can be tailored with divergent thermal conductivity levels to dissipate heat or retain it as required by the application.

Surface finishes

The texture and surface finish of TPE moulds considerably affect the touch, grip, aesthetic, and performance. Custom surfaces can be smooth, patterned, or engraved according to aesthetic design needs and functional usage. For instance, antislip texturing improves grip in hand tools, automotive interiors, and medical devices. Conversely, a smooth finish may be required for aesthetic consumer goods.

Colour and transparency

TPE moulds are highly customisable in colour and optical clarity. Several colouring agents offer the whole spectrum of colours for branding or product design purposes. Additionally, the transparency of tinctures can range from opaque to clear, allowing for design flexibility. This clarity makes internal components viewable or lending to appealing visual aesthetics. Such aesthetic customisation is especially pertinent in consumer products, medical devices, and flexible packaging.

Stiffness and elasticity ratios

TPE moulds can be tailored for different ratios of stiffness to elasticity. This parameter is crucial for several applications where the deformation behaviour needs to be specific. For example, the TPEs may exhibit greater ratios suitable for seals and gaskets with performance low elasticity demands. Conversely, applications which undergo dynamic loads, such as automotive suspension components, may require lower stiffness ratios.

TPE material formulation

The TPE materials' formulation ascertains its performance properties. Quality moulds are usually made from thermoplastic blends, styrenic block copolymers, and thermoplastic vulcanates. These polymers confer various properties include flexibility, chemical resistance, and durability. Polymeric blends and alloys, for example, create moulds with optimally enhanced flow characteristics, mechanical strength, and thermal stability. Confirm that the supplier uses high-grade TPEs with a proven track record in the desired application. The materials' formulation determines the end product's sterility, texture, strength, and operability.

Production processes and techniques

The quality of TPE plastic moulds is influenced by the manufacturing processes employed. Good suppliers use advanced and efficient production methods, including injection moulding, compression moulding, and blow moulding. These techniques ensure uniformity, dimensional accuracy, and superior surface finish. Additionally, consider suppliers who utilize innovative technologies like 3D printing for prototyping. This technology helps reduce lead times and allows for quick adjustments during the design phase. Confirm that the supplier's production standards align with industry best practices.

Mould design and engineering expertise

Furthermore, the mould design integrity considerably impacts its performance. Quality moulds feature expert engineering to ensure functionality, aesthetic appeal, and manufacturability. Avoid suppliers with low TPE plastic mould quality or without a capable team of designers and engineers. They should possess experience dealing with complex geometries and have design software proficiency. This proficiency enables accurate simulations and analyses. Such a team will realise moulds that meet performance requirements and maintain consistency in high-volume production.

Quality control measures

Quality control protocols are indispensable in TPE mould production. Hence, select suppliers instituting rigorous inspections and testing throughout the manufacturing process. Such quality assurance activities may include dimensional metering, mechanical performance evaluation, and sterility testing. Acceptable defect rates and stringent quality control standards are crucial to ensure the moulds' reliability and durability. Further, consider the certifications held by the supplier.

Lead times and scalability

Equally important is the supplier's production scalability and lead times measurement. Further, avoid suppliers unable to meet quick and flexible demands. Their capacity to modify production volume seamlessly with the requirements in peak and non-peak seasons influences the supply chain directly. Hence, confirm that the supplier's manufacturing schedule aligns with set project deadlines. Also, ascertain their ability to fulfill both short-run and long-run production orders without foreclosure on quality.

What benefits do TPE plastic moulds have over silicone ones?

TPE moulds typically have greater hardness ranges, are easier to process, and have lower costs. Unfortunately, silicone moulds have a broader temperature and environment resistance range and superior flexibility. Therefore, the selection will depend on the specific application requirements.

Are TPE moulds suitable for outdoor applications?

Yes, they are suitable. TPE moulds have UV stabilised, and weather-resistant properties making them ideal for outdoor applications such as automotive parts, garden tools, and outdoor furniture.

Can TPE plastic moulds be recycled or reused?

Yes, they can be recycled. One of the notable advantages of TPE moulds is their recyclability. Thus, they can be reused in many applications. This feature contributes positively to their sustainability profile compared to conventional thermosetting elastomer moulds.