(7829 products available)

The touch screen CNC controller regulates the computer's numerical control of machines through human-machine interaction. Those controllers with a touch screen tend to be better. There are many types of them. Here are five popular types.

iMachinist 2D/3D CNC Control App

This app is designed for use with an iOS device as an iMachinist WiFi-based CNC controller. It offers an intuitive and user-friendly interface, and it allows users to control and monitor CNC operations.

GRBL Touch

This is a lightweight CNC control software based on GRBL. It's mainly designed to control small and lightweight CNC machines and routers. The software interface is user-friendly, and it allows users to directly control the CNC machine.

LinuxCNC

LinuxCNC is an open-source software that controls CNC machines running on the Linux operating system. It offers a wide range of control functions and configuration options, making it suitable for various types and specifications of CNC machines.

Candle

The touch screen CNC controller software is designed to control an open-source GRBL CNC machine. It has an easy-to-use interface, so users can easily operate and monitor the CNC machine.

UCCNC

This is CNC control software based on a computer that can work with an Ethernet controller. UCCNC provides precise control functions and an efficient operating interface, suiting it for various industrial applications.

Flexible Materials:

They typically consist a set of thin, flexible circuit boards and can be easily manufactured to work with nearly any material. Some of them can also surface more than one layer to add more features, like multiple touch zones.

Controller Function:

A flexible touch screen CNC controller works by interpreting the user's input actions (like finger presses) as commands to be executed by the machine. The controller then processes these commands and sends signals to control the motion of the CNC machine.

Signal Transmission:

Flexible touch screens usually send signals through a specific type of circuit or film. That's typically capacitive, resistive, or optical technology. This mechanism forms the basis of user interaction and command execution within the CNC machine.

Maintaining a flexible touch screen CNC controller is crucial to ensure its longevity and optimal performance. By adhering to the maintenance tips outlined below, users can keep their controller in good condition and prevent common problems associated with neglect.

FIFO Cleaning:

Cleaning the controller in a specific order is essential to avoid cross-contamination. Always use a clean, dry cloth to wipe the surfaces of the controllers, following the prescribed cleaning sequence.

Use of Trolley:

Using a trolley to transport controllers instead of carrying them can help prevent accidental drops and damage during the controller. Trolleys provide better stability and protection for the equipment.

Avoid Transfer Fans:

Avoid using transfer fans to cool the temperature of multiple controllers at once during maintenance. Fans can spread dust and contaminants to controller surfaces, compromising their cleanliness and integrity.

Regular Inspections:

Conducting regular inspections of the flexible touch screen CNC controllers is vital to identify any potential issues early on. Users should check for signs of wear, damage, or malfunction and address any problems promptly.

A tactile CNC controller solves most problems with traditional CNC controllers by offering a tactile and engaging interface. Consequently, such touch screens are applicable in a range of industries and scenarios.

Manufacturing industry

In the manufacturing sector, touch screen CNC controllers can be found in factories where precise and automated jobs are done. These include the making of car parts, machines, and airplanes. Such industries use the controllers to help Machines like lathes, mills, and routers work better as they cut and form materials with high accuracy.

Robotics and automation

Apart from manufacturing, the controllers also find use in industries that deal with robots and automated systems. These include machines that make parts for cars, packing systems, and assembly lines. With touch screen controllers, robots can be directed precisely to perform tasks like welding, picking, and placing, as well as assembling. This leads to greater accuracy and smoother automation of work.

Woodworking and carpentry

Touch screen CNC controllers are commonly used in the woodworking industry. This includes factories that make furniture and custom carpentry jobs. With such screens, CNC machines like routers, millers, and lathes meant for woodworking can be operated easily. This leads to more precise cutting and better forming of wood materials when making cabinetry, furniture, and decorative pieces.

Medical device manufacturing

When it comes to the production of medical devices, quality and precision are key. Touch screen CNC controllers are used in the workshops that make medical devices, ensuring reliable product quality. As a result, prostheses, braces, and other medical aids are made according to exact standards.

Jewelry and precision instrument industry

CNC controllers with touch screens are commonly used in jewelry-making and precision instrument workshops. Such jobs demand high precision and more complicated work to be done. Devices like mini lathes, milling machines, and engraving machines rely on these controllers to help ensure that exactly as needed, fine jewelry and high-quality precise instruments are produced.

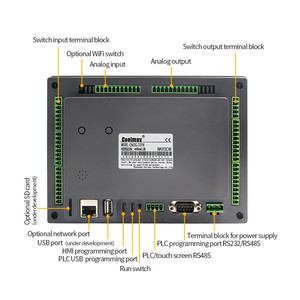

Luckily, several things can help buyers looking for a suitable CNC controller for their machine. First is to determine machine compatibility. Buyers need a touch screen CNC controller that matches their current or intended CNC machines. They should consider the machine's specifications like its structure, working environment, and material. The required performance also influences the parameters of the controlling device to look for, such as the spindle speed and the axis that needs to be controlled.

Next, buyers need to evaluate the controller's functionality against their needs. They may have to prioritize certain features like program memory, user interface, and processing power. For instance, a controller with a user-friendly interface and high processing power will ensure faster operation and seamless management of complex tasks. Protection from external elements is key to prolonging a controller's lifespan. In this regard, buyers should look for a controller with a robust and reliable construction. Also, they must ensure the touch screen device's resistance to dust, moisture, and mechanical damages.

Buyers must also consider the controller's operating system. Some CNC controllers use Windows or Linux, while others utilize a proprietary system. Those with a more common operating system may offer easier integration and customization options. When comparing the communication protocols supported by different controllers, buyers should consider their systems' requirements and architecture. The controller should support the necessary protocols for smooth data exchange.

Finally, buyers should think about the amount of support and training required after purchasing the controller. Some models have extensive documentation and training resources, while others may offer limited support. Consider benefits like life tech support and software updates should the controller need servicing in the future.

Q1. Does a CNC touch controller work for all materials?

A1. No. A CNC machine with a touch controller is mainly designed for a specific material, as mentioned in the controller's specifications. Normally, they are made to work with metal, wood, or marble, among other materials. To achieve the best results when processing different types of materials, adhering to the recommended ones is crucial.

Q2. How user friendly is a CNC touch screen controller?

A2. Generally speaking, CNC controllers are designed to be as straightforward as possible so that even individuals without formal training can use them successfully. However, some models are more straightforward than others. The touchscreen interface typically makes navigating menus and options more accessible than physical buttons or knobs.

Q3. What is the difference between a CNC touch screen controller and other controllers?

A3. CNC controllers can be broadly categorized based on their user interfaces and technological sophistication. The first controllers were knob and dial systems, while sophisticated ones now include touch screens and other modern features. Those with touch screens offer a more intuitive experience than their predecessors.

Q4. How does a CNC controller work without electricity?

A4. CNC machines are designed to function even without power. The machine has manual backup controls that can be used during a power outage. One can manually move the axes and clamp the workpieces, but this is not advisable.

Q5. Are all CNC machines the same size?

A5. No. CNC touch screen controllers are made in different sizes to match various types and models of CNC machines. It is essential to consider the size of the controller when looking to replace it or upgrade it to ensure that it will fit properly and function effectively.