Types of Tire Vulcanizing Tools

There are several types of tire vulcanizing tools that cater to different repair needs and scenarios. Understanding the functions and applications of each type can help you select the most appropriate tool for your tire repair requirements.

Tire Repair Kits

The essential option for quick fixes and minor punctures. These kits typically contain:

- Reamers for cleaning and enlarging puncture holes

- Insertion tools for placing repair plugs

- Repair plugs or strips for filling punctures

- Vulcanizing cement for bonding repairs

Best for: Mobile mechanics, emergency repairs, and DIY applications

Tire Patch Machines

Available in manual and electronic versions, these specialized tools:

- Apply precise heat and pressure to patches

- Create strong chemical bonds with tire surfaces

- Ensure patches adhere securely to the tire's inner surface

- Provide consistent results with temperature controls

Best for: Professional tire shops and consistent repair quality

Vulcanization Equipment

Specialized buffing machines that:

- Prepare tire surfaces by creating textured areas

- Remove damaged rubber and contaminants

- Enhance adhesion of repair materials

- Create optimal surface conditions for bonding

Best for: Retreading operations and professional repair shops

Hot and Cold Cure Adhesives

Essential components in the tire repair process:

- Hot cure adhesives: Require heat activation for chemical bonding

- Cold cure adhesives: Bond at room temperature without external heat

- Both ensure repaired areas integrate with surrounding rubber

- Help maintain structural integrity of the tire

Best for: Different repair environments and equipment availability

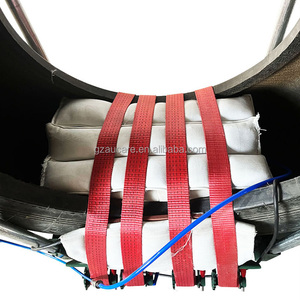

Tire Curing Presses

Advanced equipment essential for retreading operations:

- Control precise temperature and pressure parameters

- Ensure consistent bonding of tread to tire casing

- Feature programmable cycles for different tire types

- Extend the lifespan of tires through professional retreading

Best for: Commercial retreading facilities and high-volume operations

| Tool Type | Application | Complexity | Best For |

|---|---|---|---|

| Tire Repair Kits | Minor punctures, small holes | Low | DIY users, mobile repairs |

| Tire Patch Machines | Inner liner repairs, larger damages | Medium | Professional tire shops |

| Vulcanization Equipment | Surface preparation | Medium | Retreading operations |

| Hot/Cold Cure Adhesives | All repair types | Low to Medium | All repair environments |

| Tire Curing Presses | Complete retreading | High | Commercial operations |

Specifications & Maintenance of Tire Vulcanizing Tools

Key Specifications for Selection

When selecting appropriate tire vulcanizing repair tools, consider these critical specifications:

Vulcanizing Patch Specifications

- Match patch size and type to tire dimensions

- Select appropriate shape to completely cover damaged area

- Consider reinforced patches for high-stress applications

- Verify compatibility with specific tire compounds

Vulcanizing Adhesive Properties

- Choose tire-specific formulations for optimal bonding

- Verify temperature range compatibility

- Consider cure time requirements for your operation

- Check shelf life and storage requirements

Vulcanizing Tool Quality Factors

- Verify heating element consistency and reliability

- Check pressure application mechanism functionality

- Ensure proper calibration of temperature controls

- Confirm tool is designed specifically for tire repair

Professional Tip: Always follow manufacturer's instructions when selecting vulcanizing tools and materials. This ensures proper compatibility, effective repairs, and maintains any applicable warranties on both the tools and repaired tires.

Maintenance Requirements

Proper maintenance of tire vulcanizing tools is essential for ensuring reliability, safety, and longevity. Implement these maintenance practices:

| Maintenance Task | Frequency | Importance | Notes |

|---|---|---|---|

| Clean tools after use | After each use | High | Remove all adhesive residue and contaminants |

| Inspect for wear/damage | Weekly | Critical | Replace damaged components immediately |

| Check heating elements | Monthly | High | Verify even heating and temperature accuracy |

| Lubricate moving parts | Monthly | Medium | Use manufacturer-recommended lubricants |

| Calibrate temperature controls | Quarterly | High | Ensure accurate temperature readings |

| Check electrical connections | Quarterly | Critical | Prevent electrical hazards and ensure consistent power |

Safety Warning: Always disconnect power before performing maintenance on electrical vulcanizing tools. Allow equipment to cool completely before cleaning or inspecting heating elements to prevent burns or injuries.

How to Choose Tire Vulcanizing Tools

Selecting the right tire vulcanizing tools requires careful consideration of several critical factors. A thoughtful approach ensures you invest in equipment that meets your specific repair needs.

Tire Size and Type Considerations

Different tires require specific vulcanizing approaches:

- Large, heavy-duty tires need robust heating capabilities

- Low-aspect-ratio tires require specialized repair techniques

- Specialty tires with unique tread designs may need specific tools

- Performance tires often demand precision vulcanizing equipment

Key factor: Match tool capabilities to your typical tire inventory

Damage Assessment Requirements

Evaluate tools based on common repair scenarios:

- Consider damage location accessibility needs

- Assess capabilities for different damage extents

- Determine if specialized curing methods are needed

- Factor in remaining tread depth considerations

Key factor: Choose tools versatile enough for your typical repairs

Manufacturer Guidelines Compliance

Tools should align with industry standards:

- Verify compatibility with major tire brands' repair protocols

- Ensure tools meet warranty-preserving requirements

- Select equipment that supports recommended curing processes

- Consider tools approved by tire manufacturers

Key factor: Maintain tire warranties through proper tool selection

Portability and Convenience Features

Consider operational requirements:

- Assess weight and size for transportation needs

- Evaluate setup time for emergency repair situations

- Check for user-friendly interfaces and controls

- Consider power source requirements (electric, battery, etc.)

Key factor: Balance portability with performance capabilities

Selection Tip: When investing in tire vulcanizing tools, consider future needs as well as current requirements. Purchasing slightly more versatile equipment than immediately necessary can accommodate business growth and changing tire technologies without requiring premature replacement.

Safety Features

Prioritize equipment with these safety elements:

- Temperature control systems with automatic shutoff

- Overheat protection mechanisms

- Proper insulation and cool-touch exteriors

- Ventilation features for adhesive fume management

- Emergency stop functions on powered equipment

Quality & Durability Indicators

Look for these signs of quality construction:

- Corrosion-resistant materials for long-term durability

- Precision-engineered heating elements for even temperature

- Reinforced construction at stress points

- Quality electrical components and connections

- Comprehensive warranty coverage

DIY Tire Repair Using Vulcanizing Tools

Tire repair using vulcanizing tools is a systematic process that can be performed effectively with proper techniques and equipment. While professional repairs are recommended for critical damage, many minor repairs can be successfully completed as DIY projects.

Step-by-Step Vulcanizing Repair Process

Assess the damage - Determine if the tire is repairable based on damage location, size, and severity. Sidewall damage or large tears generally require professional attention or tire replacement.

Prepare the work area - Ensure the tire is properly secured and the damaged area is accessible. Clean the surrounding area to remove dirt and debris.

Remove foreign objects - Carefully extract any nails, screws, or other objects causing the puncture using appropriate tools. Take care not to enlarge the damage.

Clean and prepare the damaged area - Use a tire buffer or rasp tool to create a rough, clean surface around the damage. This enhances adhesion for the repair materials.

Apply vulcanizing cement/adhesive - Spread an even layer of vulcanizing cement over the prepared area, extending slightly beyond the damaged region. Allow it to set according to manufacturer instructions.

Prepare and apply the patch - Cut a patch that extends beyond the damaged area. Remove backing material and press firmly onto the adhesive, smoothing out air bubbles.

Apply heat (if required) - For hot vulcanizing repairs, apply the heating tool according to manufacturer specifications to activate the adhesive and create a permanent bond.

Verify repair integrity - After cooling, check that the patch is securely bonded and the repair seals the damage completely. Reinflate the tire and check for leaks.

Safety Warning: DIY tire repairs should only be attempted for minor damage in non-critical tire areas. Sidewall repairs, large punctures (over ¼ inch), or damage near previous repairs should be handled by professionals. Always follow manufacturer guidelines and safety precautions when using vulcanizing tools.

Essential Tools for DIY Tire Vulcanizing

| Tool | Purpose | Selection Tips |

|---|---|---|

| Tire repair kit | Provides essential repair components | Choose kits with quality tools and materials |

| Tire rasp/buffer | Prepares tire surface for repair | Select durable tools with comfortable handles |

| Vulcanizing cement | Creates chemical bond with repair materials | Use fresh cement specifically formulated for tires |

| Patch material | Seals punctures and damage | Choose reinforced patches for durability |

| Heat source (if needed) | Activates hot-cure adhesives | Select tools with temperature controls |

| Tire pressure gauge | Verifies proper inflation after repair | Choose digital gauges for accuracy |

Frequently Asked Questions

The duration of tire vulcanization varies depending on several factors:

- Repair Type: Simple puncture repairs may take 30-60 minutes, while complex repairs can require several hours

- Tire Size: Larger tires require more time for proper vulcanization and cooling

- Materials Used: Hot-cure methods typically take longer than cold-cure approaches

- Professional vs. DIY: Professional equipment often provides faster curing times

For standard passenger vehicle tires with minor damage, expect approximately 1-2 hours for a complete professional repair. Commercial truck tires or specialized vulcanization may require up to 24 hours, particularly when retreading is involved.

When performed correctly, vulcanized tire repairs can be extremely durable. Professional vulcanization creates a chemical bond that integrates the repair material with the tire rubber, restoring structural integrity. The durability depends on:

- Repair Quality: Proper surface preparation and adhesive application are critical

- Material Quality: Premium vulcanizing patches and adhesives provide superior longevity

- Technique: Following manufacturer-specified procedures ensures optimal results

- Damage Severity: Minor punctures typically repair more successfully than larger damages

A properly vulcanized repair can last for the remaining life of the tire, though it's advisable to monitor repaired tires periodically for any signs of compromise.

Not all tire damage is suitable for vulcanization repair. Industry guidelines and safety standards limit repairs to specific damage types and locations:

- Repairable: Minor punctures (under ¼ inch) in the tread area

- Not Repairable:

- Sidewall damage (regardless of size)

- Large tread punctures (over ¼ inch)

- Damage near previous repairs

- Tread separation or belt damage

- Bulges or impact breaks

- Aging/weather-cracked tires

When in doubt about repair suitability, consult a professional tire technician who can assess the damage and provide appropriate recommendations based on safety standards.

Professionally performed vulcanization repairs can be safe for high-speed use when:

- The repair follows industry standards (RMA/TIA guidelines)

- The damage is within repairable parameters (size, location)

- Professional equipment and materials are used

- The repair is executed by trained technicians

- The tire is otherwise in good condition

Modern vulcanization techniques restore the tire's structural integrity when performed correctly. However, for vehicles regularly operating at very high speeds (racing, performance driving), it's often recommended to replace rather than repair tires to maintain optimal safety margins. Always follow manufacturer recommendations for high-performance vehicles.

While vulcanizing tools are primarily designed for repairs, certain aspects of tire maintenance can benefit from vulcanization technology:

- Preventive Sealants: Some internal tire sealants use vulcanizing compounds to immediately seal small punctures as they occur

- Sidewall Protection: Specialized sidewall protectors can be vulcanized to high-risk areas in certain applications

- Bead Repairs: Minor bead issues can sometimes be addressed before they cause air leakage

However, the most effective preventive maintenance includes:

- Regular tire pressure checks and maintenance

- Rotation according to manufacturer schedules

- Wheel alignment and balancing

- Proper load management and driving practices

- Protection from environmental extremes

These practices reduce the likelihood of damage requiring vulcanization repair in the first place.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4