Understanding Thermocol Mould

Thermocol moulds have revolutionized various industries due to their lightweight, cost-effective, and insulating properties. These moulds, made from expanded polystyrene (EPS), are used to shape different materials during the manufacturing process. Their versatility makes them suitable for multiple applications, from construction to packaging. In this article, we will explore the types, functions and features, applications, and advantages of thermocol moulds.

Types of Thermocol Mould

Thermocol moulds come in various shapes and sizes to meet different industrial requirements. Here are some common types:

- Standard Moulds: Available in basic shapes like cubes, spheres, and cylinders, these are used for general-purpose applications.

- Custom Moulds: Tailored to specific designs or products, ideal for specialized applications.

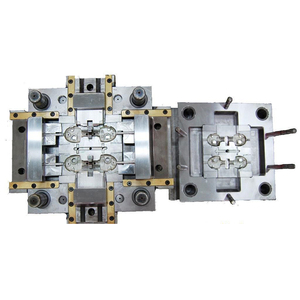

- Multi-cavity Moulds: Designed to produce multiple parts simultaneously, increasing efficiency in production.

- Heat-Resistant Moulds: Specifically made for applications that require resistance to high temperatures, suitable for the construction industry.

Functions and Features of Thermocol Mould

Thermocol moulds perform crucial roles in various industries. Their unique features make them a preferred choice in numerous applications:

- Lightweight Construction: Being lightweight allows for easier handling and transportation, reducing labor costs.

- Cost-Effectiveness: Production costs are significantly lower compared to traditional mould materials, offering budget-friendly solutions.

- Excellent Insulating Properties: Thermocol’s ability to insulate helps in minimizing energy loss, making it ideal for thermal applications.

- Easy to Mould: The material can be easily shaped into complex designs, catering to diverse manufacturing needs.

- Water-Resistant: Thermocol is resistant to moisture, making it a great choice for outdoor applications.

Applications of Thermocol Mould

The versatility of thermocol moulds ensures their usage in myriad applications across different industries:

- Construction: Often used for creating lightweight partitions, decorative features, and insulation components in buildings.

- Packing: Employed in packaging fragile items, providing cushioning and protection during transit.

- Furniture: Used in the manufacture of lightweight furniture components to reduce overall weight without sacrificing strength.

- Arts and Crafts: Favored by artists and hobbyists for creating sculptures, models, and other decorative pieces.

- Event Decoration: Widely used in creating backdrops, props, and customized decorations for events and parties.

Advantages of Using Thermocol Mould

Choosing thermocol moulds comes with several distinct advantages that enhance productivity and performance:

- Eco-Friendly Options: Many manufacturers now produce thermocol moulds using recyclable materials, making them a sustainable choice.

- Customization Potential: Easy to modify designs for varied applications, ensuring flexibility in production.

- Durability: Thermocol is not only resistant to wear and tear but also provides long-lasting performance.

- Ease of Use: Simple to handle and integrate into existing manufacturing processes without the need for specialized equipment.

- Sample and Prototype Creation: Ideal for creating prototypes in design phases before final production models are developed.