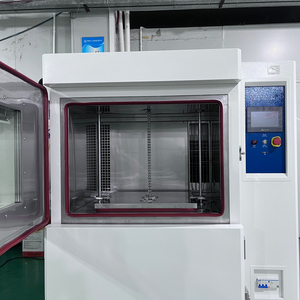

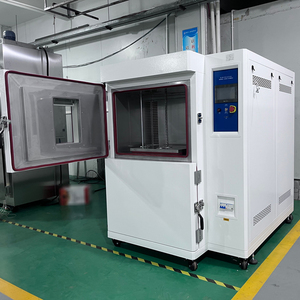

Understanding Thermal Shock Testing Machines

A thermal shock testing machine is an essential device used in various industries to assess the durability and reliability of materials and components under extreme temperature variations. This testing equipment is designed to expose specimens to rapid changes in temperature, helping to identify potential weaknesses and failure points in materials.

Types of Thermal Shock Testing Machines

- Small Chamber Thermal Shock Testers: Ideal for testing small components and materials, these machines are compact and efficient, making them suitable for laboratories with limited space.

- Large Chamber Thermal Shock Testers: Designed for larger materials or multiple specimens, these testers can accommodate sizable items, offering a more comprehensive analysis.

- Portable Thermal Shock Testers: These are lightweight, mobile units that allow for testing to be conducted in different locations, offering flexibility without compromising on effectiveness.

- Custom Thermal Shock Testers: Tailored to meet specific industry needs, these machines can be configured to perform unique tests based on client requirements.

Applications of Thermal Shock Testing Machines

- Aerospace Industry: Used to ensure components can withstand the extreme temperatures associated with high-speed flight and varied atmospheric conditions.

- Electronics Testing: Essential for testing circuit boards and electronic components to verify their reliability when exposed to thermal cycling.

- Automotive Sector: Helps assess materials used in vehicles, ensuring they remain functional under varying weather conditions and temperatures.

- Materials Research: Valuable in the research and development of new materials, allowing scientists to evaluate the performance of innovative solutions under stress.

Features and Advantages of Thermal Shock Testing Machines

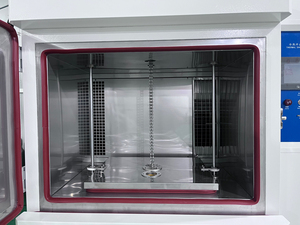

- Rapid Temperature Change: Capable of quickly transitioning between high and low temperatures, providing accurate results that reflect real-world conditions.

- Precise Control: Offers programmable temperature settings and cycles, ensuring consistent testing protocols that yield reliable data.

- User-Friendly Interface: Many modern machines come equipped with touchscreen controls and digital displays for easy operation and monitoring.

- Data Logging Capability: Most thermal shock testers can record and analyze the results over multiple tests, offering valuable insights into material performance.

- Safety Features: Advanced safety protocols are integrated, including automatic shut-offs and alarms, to ensure the safety of operators during testing.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4