All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1794 products available)

Functionality

The design includes levers, pulleys, and weights or screw mechanisms. It delivers precise and controlled force application to measure spring strength accurately.

Advantages

Mechanical testers are often more durable and require less maintenance than electronic models, making them suitable for basic testing needs. They function effectively in environments where power supply may be inconsistent.

Disadvantages

However, they could be less accurate and more labor-intensive, requiring manual input for readings.

Functionality

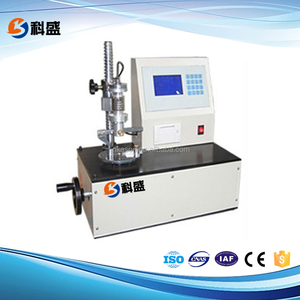

This machine uses sensors and electronic displays to measure the spring's responses. It records data automatically and shows the results on a screen.

Advantages

Electronic testers offer higher precision, faster testing, and the ability to record and analyze data quickly. These features are beneficial for quality control in production settings.

Disadvantages

These machines may be more expensive upfront and require power sources or battery recharges.

Functionality

This machine uses liquid pressure to test springs. A pump pushes a cylinder, causing the spring to bend or break.

Advantages

They handle large forces, making them ideal for big or strong springs. They are also very accurate.

Disadvantages

They are often bulkier and more costly than simpler machines. Regular upkeep is needed to keep them working well.

Functionality

This machine can test springs in many ways. It measures strength, flexibility, and other properties with different tools.

Advantages

They are very flexible, allowing for comprehensive spring testing. They are useful in research and development labs for diverse testing needs.

Disadvantages

However, these machines might be more complex to operate and pricier than standard models.

Detailed Explanation

The load capacity of leaf spring test machines refers to the maximum force or weight that the machine can handle during testing. This capacity is crucial because different types of leaf springs are designed for specific load-bearing applications in vehicles.

How It Affects Product Performance

If a test machine does not have enough load capacity, it cannot give correct results. This issue leads to unsafe spring designs.

Detailed Explanation

Tensile strength measures the maximum amount of stretching a material can endure before breaking. In leaf spring testing machines, this property is important because these springs need to carry heavy weights without snapping. High tensile strength ensures that the testing machine remains reliable and durable under demanding conditions.

How It Affects Product Performance

Springs that bend or break easily will not support vehicles properly. Weak springs cause rough rides and early wear on suspension parts.

Detailed Explanation

Speed matters when testing how quickly a leaf spring can stretch. Faster machines save time during production testing or research.

How It Affects Product Performance

Lowers the overall production efficiency. Delays identifying weak springs that need replacing. In large designs, it may take too long to test a few parts.

Detailed Explanation

This system tracks how much power the leaf spring uses when it stretches. It helps record the stretching and any changes to the spring over time. This system shows if the spring is good or needs replacing.

How It Affects Product Performance

Springs with little power usage provide a smooth ride. Cars needing too much power to stretch the springs will be rough and wear out fast.

Role of Product in the Use Case

Leaf spring test machines check truck springs for proper strength and flexibility. Provides accurate measurements and helps design reliable suspension systems. The data prevents testing delays or failures.

Benefits for the User

This process leads to safer rides and longer wear for springs and shock absorbers. Reduces road vibrations and improves handling.

Possible Challenges

Leaf spring test machines must run fast to meet high production needs. Complex operations may slow down testing.

Competitors and Market Alternatives

Mechanical testers may be simpler but can perform the required strength tests. They provide lower costs for large plants.

Role of Product in the Use Case

Machines perform fatigue tests, flexing springs repeatedly to ensure reliability under flight conditions. Provides accurate and fast testing results, enabling thorough spring evaluations.

Benefits for the User

The process prevents spring failures during missions, boosting safety and confidence. Promotes smooth landings and stable aircraft control.

Possible Challenges

Testing demands may cause mechanical testers to work harder than normal. Results may be impacted if machines overheat.

Competitors and Market Alternatives

Hydraulic testers can support very high loads and are suitable for big springs. They help labs manage complex testing efficiently.

Role of Product in the Use Case

The machines check spring strength for large equipment like excavators and bulldozers. Provides flexibility in testing various spring types.

Benefits for the User

This benefit results in fewer unexpected breakdowns and lower repair costs. Ensures that operators can rely on their machines.

Possible Challenges

The need for accurate testing could lead to potential errors if quick results are prioritized over thorough checks.

Competitors and Market Alternatives

Simple mechanical testers might be lower in cost but still meet basic needs for strength checks.

It is vital to identify the specific parameters that dealers need to measure in springs. This step involves determining whether they need to evaluate load capacity, tensile strength, or spring constant. It is essential to consider the types of materials and configurations they will test. People should also factor in how often they expect to perform tests and whether they need static or dynamic assessment capabilities. It helps in selecting a machine that meets precise needs.

Buyers should ensure the machine they select handles the size and load of the springs they will test. Large springs need big machines to handle the weight. Small springs work well in compact machines. This selection helps maintain testing precision and prevents tool damage.

It will be great if buyers could look for important features and functions in available options. They can focus on features such as automatic data collection, high testing speed, and live feedback. These factors can help them improve overall performance and efficiency. If possible, they have to seek machines with flexible testing methods. Such machines will allow for future expansions in needs or requirements.

It is vital to ensure the machine meets safety standards and certifications. People should check for ISO or ASTM endorsements. Such certifications ensure the tool works effectively and remains safe over time.

Finally, it is necessary to compare the cost of various machines against the features they offer. Buyers should look for models that provide the best value, considering performance and building quality. This step helps them make well-informed purchases.

A1. Reliable steel alloys are widely used for making leaf springs. They offer ideal flexibility and strength. Chromoly steel is a popular choice for leaf springs as it is both tough and light. Other suitable metals for making leaf springs include carbon steel and titanium alloys. These materials give great resistance to bending without breaking.

A2. While machines do not have a set lifespan, their duration mainly depends on usage and upkeep. It is important to properly maintain some of the devices to prolong their lifetimes. Regularly servicing the machines ensures they remain accurate and safe to use. Machines with high demands may need more frequent servicing. This is because they endure greater stress during use.

A3. Some advanced electronic leaf spring testers may have waterproof features. These features protect internal sensors and components from damage. Although hydraulic testers can be designed to function in wet conditions, it is not always typical for them to be waterproof. Manufacturers do not always add this feature. Hence, it is necessary for buyers to check the specifications of the specific models they intend to purchase.

A4. This machine requires regular inspections and servicing. Business owners should lubricate moving parts to minimize wear and friction. Cleaning the device aids in preventing damage caused by debris or residue accumulation. Calibrating the machine frequently ensures it gives accurate results. For electrical testers, protection covers help prevent damage to internal components.

A5. Buyers can customize the machines by adding features that will allow them to handle specific loads. Integrating advanced data collection systems will help in analysis and reporting. Adding software that enables remote access to test data could enhance performance. Dealers could also incorporate additional sensors to gather more detailed metrics on spring performance.