Understanding Tension Spring Material

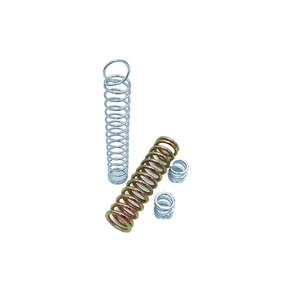

Tension springs are essential components widely used in various machinery and applications. The choice of the right tension spring material plays a crucial role in determining the spring's performance, durability, and suitability for specific uses. Different materials offer unique properties, making them ideal for various applications. This guide explores the types, features, and advantages of tension spring materials to help you make an informed decision.

Types of Tension Spring Material

Tension springs can be manufactured from a range of materials, each offering distinct performance characteristics:

- Stainless Steel: Known for its excellent corrosion resistance and strength, stainless steel is a preferred choice in environments where moisture and chemicals are present.

- Carbon Steel: Often used in standard applications, carbon steel springs can handle significant stresses and are cost-effective, making them ideal for general usage.

- Music Wire: This type of high-carbon steel is recognized for its high tensile strength and elasticity, making it particularly suitable for high-performance applications.

- Alloy Steel: Alloy springs typically resist deformation under heavy loads and extreme conditions, making them suitable for aerospace and automotive uses.

Features of Tension Spring Material

The features of tension spring materials play a pivotal role in their functionality and the applications they can serve. Key attributes include:

- Tensile Strength: The ability to withstand heavy pulling forces without breaking is crucial. Materials like music wire and alloy steel provide superior tensile strength.

- Corrosion Resistance: For applications exposed to harsh environments, materials like stainless steel are essential for extended lifespan and reliability.

- Elasticity: The ability to return to the original shape after deformation is vital for maintaining functionality. High-quality materials ensure effective elasticity.

- Temperature Tolerance: Some materials can endure extreme temperatures without compromising their properties, making them suitable for specialized environments.

Advantages of Using Quality Tension Spring Material

Choosing high-quality tension spring materials has numerous advantages that enhance the usability and longevity of springs:

- Increased Durability: Quality materials are less prone to fatigue and wear, ensuring that tension springs maintain their performance over extended periods.

- Better Performance: Utilizing the appropriate material can optimize load handling capabilities, leading to improved overall system performance.

- Enhanced Safety: Quality materials reduce the likelihood of failures, ensuring safer operation in industrial and commercial applications.

- Cost-Effectiveness: While higher-quality materials may come with a greater initial investment, their longevity and reduced maintenance needs often lead to lower overall costs.