Introduction to Temperature Forcing System

A temperature forcing system is an innovative solution designed to regulate and control temperature levels in various environments, ensuring optimal conditions for processes or products. These systems play a vital role in sectors such as agriculture, pharmaceuticals, and manufacturing, where precise temperature control is critical for success. Utilizing advanced technology, temperature forcing systems maintain desired climatic conditions, protecting sensitive materials and enhancing productivity.

Types of Temperature Forcing Systems

Temperature forcing systems come in various types, each designed to suit specific needs and applications:

- Passive Temperature Forcing Systems: Utilizes natural elements or circulation techniques like ventilation and thermal mass to maintain temperatures without mechanical assistance.

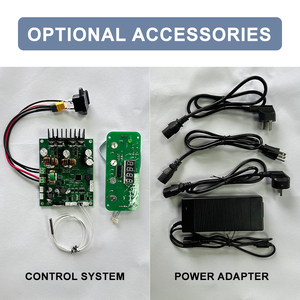

- Active Temperature Forcing Systems: Incorporates mechanical components such as heaters, chillers, fans, or compressors to regulate temperature actively.

- IoT-enabled Temperature Forcing Systems: Smart systems integrated with the Internet of Things (IoT) technology, providing remote monitoring, control, and data analytics capabilities.

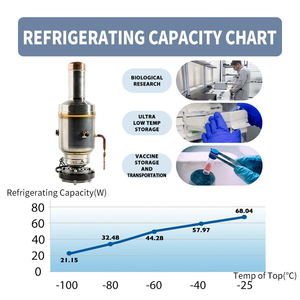

- Refrigeration Systems: Specialized temperature forcing systems that maintain low temperatures, crucial for food storage, pharmaceuticals, and chemical products.

Applications of Temperature Forcing Systems

Temperature forcing systems find applications in diverse fields, demonstrating their versatility and necessity:

- Agriculture: Used in greenhouses to enhance plant growth by providing optimal climatic conditions, critical moisture levels, and specific temperature ranges.

- Pharmaceuticals: Essential for storing and transporting temperature-sensitive medications, vaccines, and laboratory samples, ensuring efficacy and compliance with regulatory standards.

- Manufacturing: Vital in production processes where material properties can be affected by temperature, such as in plastics, textiles, and electronics.

- Laboratories: Employed for experiments requiring precise temperature conditions, impacting results and ensuring repeatability.

Features and Advantages of Temperature Forcing Systems

Temperature forcing systems come equipped with numerous features, each offering distinct advantages:

- Precision Control: Advanced sensors and controls maintain desired temperature ranges, ensuring stability for sensitive processes and products.

- Energy Efficiency: Designed with energy-saving technologies, reducing operational costs while maintaining efficiency.

- Remote Monitoring: IoT integration allows real-time monitoring and adjustments from anywhere, facilitating proactive management.

- Robust Design: Built to withstand challenging environments, ensuring long-term reliability and performance.

- Customization: Systems can be tailored to specific applications, accommodating unique requirements for diverse industries.