All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(57 products available)

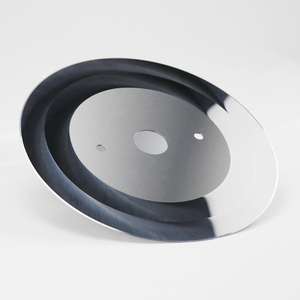

The TBM cutter head is the most crucial part of a TBM machine. It can be divided into several types according to the cutting method:

Specifications of TBM cutter heads

Maintenance of TBM cutter heads

Regular inspection: Regularly inspect the TBM cutter head for signs of wear or damage to cutting elements, bearings, seals, etc. If any anomalies are discovered, they should be addressed promptly to avoid further damage to the cutter head.

Lubrication: Ensure that the cutter head is properly lubricated to reduce friction and heat generation during the cutting process, which protects the cutter head and extends its service life.

Debris removal: Remove debris from the cutter head at regular intervals to prevent blockages and ensure smooth cutting and operation.

Replacement of cutting elements: The cutting elements of the TBM cutter head will wear out over time due to the harsh environment and high-stress conditions encountered during the excavation process. Therefore, it is necessary to replace the cutting elements regularly to maintain the cutter head's cutting efficiency.

Proper operation: Train operators on proper TBM cutter head operation techniques to avoid misuse or excessive force during operation, which can cause premature wear and damage to the cutter head.

Environmental protection: When performing maintenance on the cutter head, it is important to pay attention to environmental protection. Properly handle waste such as worn cutting elements to avoid environmental pollution.

As a crucial part of the tunnel boring machine, the TBM cutter head plays a significant role in various industries and projects.

Tunnel boring machines are widely used in underground mining. They can be used to mine coal, ore, or other mineral resources. TBM cutter heads can break rock and other hard materials efficiently, quickly, and safely. What's more, they can create tunnels and access ways for mining operations.

Tunnel boring machines and cutter heads are commonly used in urban construction projects. They can be used to excavate subways, tunnels, pipelines, and other underground infrastructure. TBM cutter heads can efficiently excavate the soil and rocks under the city, creating a secure working environment.

Tunnel boring machines and cutter heads are often used in hydropower projects. They can be used to excavate tunnels for water diversion, power generation, and other purposes. TBM cutter heads can safely and efficiently excavate hard rock and bedrock, ensuring the smooth progress of hydropower projects.

Tunnel boring machines and cutter heads are widely used in transportation infrastructure construction. They can be used to excavate tunnels for highways, railways, subways, and other transportation projects. TBM cutter heads can excavate tunnels in various terrains, providing important support for the development of transportation infrastructure.

TBM cutter heads are often used in geotechnical engineering projects. They can be used to excavate tunnels for deep foundations, dams, slopes, and other geotechnical structures. TBM cutter heads can precisely control the excavation direction and speed, ensuring the stability and safety of the engineering construction.

When selecting a TBM cutter head, it's important to consider the following:

It is important to know the diameter of the tunnel or shaft that the cutter head will be working in. The diameter of the cutter head should match the required tunnel diameter for the project. This ensures that the TBM can excavate the tunnel to the desired size.

This is one of the most important factors to consider when selecting a cutter head. The type of soil or rock formation in which the TBM will be operating will determine the appropriate type of cutter head to use. For example, open gripper cutter heads are suitable for cohesive soils, while disc cutter heads are better for hard rock. It is essential to choose a cutter head that matches the specific soil or rock conditions of the tunneling project to ensure effective excavation and minimal cutter wear.

Some projects may require a specific tunnel shape or a very smooth tunnel wall finish. Certain types of cutter heads are better suited to achieve these results. For example, single-disc cutters can produce precise tunnel shapes, while center cutter heads are better for achieving a smooth tunnel wall. It is important to consider the desired tunnel shape and finish when selecting a cutter head for a project.

Different types of cutter heads have varying excavation rates and efficiency levels based on the specific project requirements. For example, disc cutter heads are often chosen for their high-speed excavation in hard rock, while single-gripper cutter heads are selected for their efficient excavation in cohesive soil. It is important to assess the project's required excavation rate and efficiency needs when choosing a cutter head, in order to select a type that can meet the project's demands.

Project budget and cost considerations are also important when selecting a cutter head. The initial cost, maintenance requirements, and cutter life of each type of cutter head should be evaluated to determine the best fit for the project budget. While some cutter heads may have higher initial costs, they could offer better long-term value through lower maintenance expenses and longer cutter life. It is important to weigh the project's budget and cost considerations against the performance and durability of different cutter head options to choose the most cost-effective solution for the specific tunneling project.

Q1: What is the TBM cutter head made of?

A1: A typical TBM cutter head is made of cast steel, which is a durable and hard-wearing metal alloy. In some specialized applications, the cutter head may be made of other materials, such as tungsten carbide inserts or abrasion-resistant alloys, depending on the cutting requirements and environmental conditions.

Q2: How is the TBM cutter head powered?

A2: The TBM cutter head is usually powered by hydraulic motors or electric motors, depending on the TBM's design and operating requirements. Electric motors provide precise control and are suitable for smaller TBMs, while hydraulic motors offer high power-to-weight ratios and are commonly used in larger machines.

Q3: How are the cutters of the TBM cutter head replaced?

A3: The maintenance and replacement of TBM cutters vary depending on the specific design of the cutter head. Typically, the cutters are detachable and can be replaced individually or in groups by trained technicians. The process usually involves disassembling the cutter head, removing the old cutters, and securely installing the new ones. Precise alignment and tightening of fasteners are essential to ensure proper functioning and cutting performance.