All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(10163 products available)

Today's business buyers need to know all the types available because it will enable them to serve all the customers' needs. So here are the several types that almost every wholesale outlet will stock.

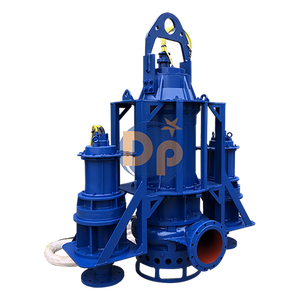

Those keying electric automatically operate by using a motor to drive the pumping mechanism. This makes them very efficient at removing water. Their very high productivity, which makes them good for heavy-duty situations like construction areas, mines, and floods, is one of the reasons they are so well-liked.

Manual ones require some human efforts. Such pumps operate through levers and hand mechanisms and are called levers and hand mechanisms. In areas without power, small ones serve well. Their simplicity helps with repair, which makes them practical in rural areas.

Solar-powered options are becoming common with the rise in solar power. These pumps draw energy from solar panels, making them exceptionally effective and environmentally friendly. They are perfect for far-off areas and farms where power lines are missing or where electricity is expensive.

These pumps use pressurized fluids to work, great for places where electricity cannot be. While typically heavier, these pumps are common in exploration and underwater construction.

The submersible water pump manufacturing producing these pumps designs them to pump water to great heights. Such durable pumps work where normal ones cannot, like in deep mines or tunnels. They are strong but also quite expensive.

Specifications are part of the knowledge submersible pumps wholesalers need. And maintenance is part of the knowledge that will help these wholesalers last longer in business.

Some specs are important to know when buying submersible pumps. These specs and features are crucial when buying the said pumps:

Maintenance is simply a way of ensuring the pumps have a longer lifespan. Here are maintenance practices buyers can implement and expect:

Several businesses need submersible pumps, so it's good to know where they end up. These are the main places the pumps go.

Construction companies use them to lower water levels when digging foundations or building underground areas. Workers use them to remove water from sites so mud does not slow down the work. Large ones pump out rainwater from deep trenches and provide reliable dewatering in all weather.

Farmers rely on submersibles for irrigation. They pull up water from wells or lakes to feed crops in dry times. The pumps give farms stable water supplies to grow healthy foods year-round. Livestock also need water, and the pumps keep animals hydrated.

Mining operations frequently deal with flooded tunnels and other waterlogged areas. They depend on submersible pumps to drain these sites quickly so work can continue safely. The pumps enable mining to happen even in wet conditions.

Similar to the mining industry, the oil and gas sectors face challenges with water as well. They utilize the pumps to control water levels when drilling and extraction processes. This allows them to operate more efficiently in their extraction work. The pumps also aid in collecting produced water in their operations.

Water treatment plants use submersible pumps to process sewage and waste safely. They help move these materials through treatment systems. This protection prevents sewage overflow problems. Submersibles also support flood control systems that protect cities from heavy rains.

Manufacturing plants and other industrial facilities rely on the submersible pumps for various dewatering tasks. These include removing wastewater, managing stormwater, and keeping production areas dry and workable. Their role in dewatering helps maintain safe work conditions for factory workers.

Residential areas use submersible pumps to provide reliable water supply from wells or other sources. They deliver this water directly to people's homes for drinking, cooking, and other daily needs. The pumps also play a key role in sewage systems, helping to treat and dispose of wastewater properly.

Buyers should decide which submersible water pumps to place in stock based on demand and their own needs. These people take into account these factors before choosing which submersible pump manufacturers to work with.

Wholesalers should assess which pumps their clients require in large numbers. They should seek feedback from current clients and sales data to determine the best models to carry. They should also consider the trends and popular brands to meet customer demands.

Wholesalers have to prioritize quality for their own benefit. If the pumps fail often, customers will stop buying them. They also need durable options that require little maintenance, as clients want hassle-free choices.

Wholesalers should find manufacturers that offer pumps in various sizes and power options. This variety allows them to serve more customers. For example, if they stock both electric and manual pumps, they can meet more clients' needs.

Buyers should research the shipping costs, delivery speed, and reliability of chosen manufacturers. Information on when orders ship and arrive is critical since delays could upset clients. It is vital they work with manufacturers that meet all the clients' needs regarding timing and costs.

Buyers also consider customization options. Some clients need pumps with specific features or branding. They should find manufacturers that enable them to provide unique options.

A1: Submersible pumps work efficiently even under pressure because they go beneath the surface of water and deliver the pressure. Few pumps can handle such depths, but high-head submersible pumps can reach up to 800 meters of water. That makes them great for mines, tunnels, and deep wells, where other pumps simply can't cope.

A2: Stainless steel, as noted earlier, is great for high-water salinity areas like coastal regions. The cast iron used for impellers and volutes is also good for freshwater situations. High-strength plastics like nylon and polycarbonate are lighter and resist corrosion.

A3: Clean and dry storage is important for the pumps' longevity. Pumps are mostly stored in dry, low-humid areas so that rust and corrosion do not damage the parts. Since most of them are in warehouses, the producers store them on shelving to keep them off the ground. In some cases, producers put old pumps like the ones used in switchboard submersible pumps in protective cases. For protection, buyers should wear storage masks and cases for old pumps and those for new ones when transporting them to clients.

A4: Solar-powered and energy-efficient models use less electricity than traditional pumps. That helps reduce emissions and energy bills for users. Smart pumps that automate operation also save water by only running when needed.

A5: Solar submersible pumps are the greenest type because they use free solar energy instead of electricity from fossil fuels. This is especially helpful for users in rural areas without easy access to power lines. Other eco-friendly options are electric pumps that use less energy than gas models.