(675 products available)

A stop bead render is also known as a stop bead or stop rendering bead. This stop stop stop rendering bead is a metal or plastic strip that forms a line between two different surfaces of render. These surfaces may be different kinds of render or render and plasterboard.

The types of stop bead renders are as follows:

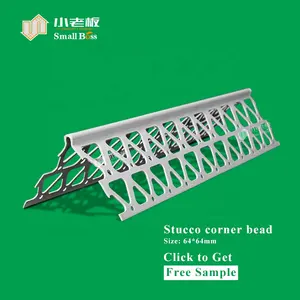

Corner Stop Bead:

A stop bead is a type of corner stop bead. It is used to create clean and rounded corners on stop render walls. The corner stop bead provides a smooth surface for the stop render to stop and helps protect the corner from damage. This corner stop bead is available in different materials like metal (aluminum and galvanized steel), plastic, and PVC.

Internal Stop Bead:

This internal stop bead is used at internal corners where two walls meet. The internal stop bead provides a neat finish and ensures that the stop render is uniformly applied. There are different types of internal stop beads, such as metal internal stop beads and PVC internal stop beads.

External Stop Bead:

External stop beads are used at external corners that are exposed to the elements. The external stop bead is designed to withstand harsh weather conditions. They come in different materials, like galvanized steel and powder-coated aluminum.

Window Stop Bead:

A window stop bead is a type of stop window stop bead. It is used to create a stop for the window frame rendering. The window stop bead ensures that the stop render is evenly applied around the window frame. This rendering stop bead is available in different sizes to accommodate different window frames.

Metal Stop Beads:

Metal stop beads are made from different metals like galvanized steel, aluminum, and stainless steel. These metals are resistant to corrosion and are long-lasting. Metal stop beads are popular because they offer good strength and support.

Plastic Stop Beads:

Plastic stop beads are lighter than metal stop beads. They are also easy to install. Plastic stop beads are resistant to rust and corrosion. They are often used in areas where metal stop beads may be prone to rust.

The stop bead is an important part of any construction project. Its main purpose is to provide a straight edge for rendered or plastered walls. The following are key features of stop beads:

Material

Stop beads are made from different materials. This depends on the requirements of the construction project. Common materials used are PVC, metal, and galvanized steel. PVC is a preferred material for many people. It is resistant to rust and corrosion. Metal stop beads are more durable. They provide a straight and clean stop line. Galvanized steel stop beads are used in external rendering projects. The galvanized coating protects them from rust.

Shape and Design

Stop beads come in different shapes and designs. This caters to different rendering and plastering needs. They can be L-shaped, T-shaped, or corner stop beads. L-shaped stop beads are used on external corners. T-shaped stop beads create a clean and defined stop line. Corner stop beads are used on internal corners and arches.

Dimensions

Stop beads have different dimensions. This includes wing length, thickness, and height. The wings' length varies from 30mm to 50mm. The thickness ranges from 0.8mm to 1.5mm. Stop beads for renders have different heights. The dimensions are important. They ensure a good bond between the stop bead and the render or plaster.

Coating

The coating on stop beads plays an important role in rendering and plastering. It prevents corrosion and ensures a good bond between the stop bead and the render. The coating also provides an anti-adhesive surface. This prevents plaster and render from sticking to the stop bead during application.

Installation Features

The stop beads have important features that make them easy to install. These includes perforated wings, adhesive backing, and pre-punched holes. The perforated wings provide a secure bond between the stop bead and the render or plaster. The adhesive backing eliminates the need for mechanical fixing. This speeds up the installation process. Pre-punched holes are used with screws or nails to create a strong stop line.

Stop beads are used in various construction and home improvement scenarios, including:

External Rendering

Stop beads are installed at the window sills, lintels, and door frames in external rendering. They provide a clean and precise finish by guiding the render application. Stop beads also create durable edges that are resistant to chipping and flaking. Additionally, they help prevent moisture penetration and maintain the structural integrity of the rendered surface.

Internal Rendering

In internal rendering, stop beads are installed at window frames, doors, and corners. They ensure straight and uniform renders, improving the overall aesthetics. Stop beads also create smooth and durable edges that enhance the longevity of the rendered surface. Additionally, they reduce the risk of damage to the rendered surface at high-traffic areas.

Skim Coating

Stop beads are installed at window frames and corners during skim coating. They ensure a smooth and even coat of plaster. Stop beads also create durable edges that reduce the need for touch-ups and maintenance. Additionally, they guide the application of plaster, resulting in a professional finish.

Brickwork

Stop beads are installed at window frames, door frames, and corners during brickwork. They ensure a neat and consistent mortar finish. Stop beads also create strong and durable mortar joints that improve the overall aesthetics. Additionally, they reduce the risk of damage to the brickwork and improve the longevity of the rendered surface.

Choosing the right stop bead render for a specific application involves considering several factors to ensure optimal performance. Here are some key factors to consider:

Material

Stop beads are made of different materials, each with advantages for particular uses. PVC stop beads are lightweight, resistant to rust, and easier to work with. They're typically used in internal plastering projects. However, metal stop beads, often aluminum, provide robustness, a clean finish, and superior resistance to mechanical damage. They're frequently favored for external render applications.

Project Requirements

Consider the specific requirements of the project. Is it an internal or external application? What's the thickness of the plaster or render? These factors will influence the choice of stop bead. For instance, galvanized steel stop beads are excellent for high-humidity areas due to their corrosion-resistant properties.

Building Codes and Standards

Ensure the selected stop bead complies with local building codes and standards. This guarantees not only the legality of the construction but also the safety and integrity of the rendered wall. Some codes might require specific materials or designs for stop beads, especially in external or high-traffic areas.

Ease of Installation

Consider the ease of installation. Some stop beads might require special tools or skills for installation. Choose a stop bead that the available workforce can easily install, or that requires minimal tools and expertise.

Aesthetic Finish

The aesthetic finish of the stop bead is crucial, particularly for internal applications. Metallic stop beads provide a cleaner and more robust finish than PVC stop beads. Consider the visual requirements of the project when selecting the stop bead finish.

Availability and Cost

While not the most critical factor, the availability and cost of the stop bead can influence the decision, particularly for large-scale projects. Some stop beads might be more readily available or cheaper in a specific region, impacting the overall project cost and timeline.

Q1: What are the common types of stop bead renders?

A1: There are different types of stop bead renders, including metal and plastic stop beads. Metal stop beads are made from durable materials like aluminum or galvanized steel. They can withstand harsh weather conditions and have a smooth finish that's resistant to rust. On the other hand, plastic stop beads are made from high-impact plastic. They are lightweight and easy to handle. They come in different colors that can be painted over or match the color of the finish coat.

Q2: What are the benefits of stop bead renders?

A2: Stop bead renders have different benefits. They improve the aesthetics of a building by providing a clean and defined edge. They also increase the durability of the exterior wall. Stop bead renders are made from materials like metal and plastic that can withstand weather elements. They also ensure a consistent finish by providing a guide for the thickness of the render coat.

Q3: Are stop bead renders easy to install?

A3: Yes, stop bead renders are easy to install. The installation process involves preparing the wall, measuring and cutting the stop beads, fixing the stop beads to the wall using nails or screws, and applying the render.

Q4: Do stop bead renders require maintenance?

A4: Stop bead renders don't require a lot of maintenance. However, it is important to periodically inspect the stop beads. Look for signs of damage or deterioration. This ensures that the stop beads continue to provide the desired support and edge definition.