All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2118 products available)

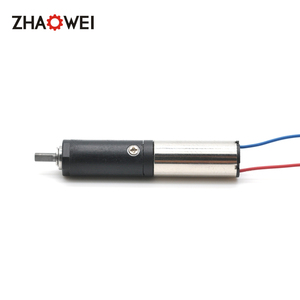

stepper motor 1.6 are an essential component in the realm of power transmission, particularly in applications requiring precise control of motion. These motors are designed to move in discrete steps, allowing for accurate positioning and repeatability, which is crucial in fields like robotics, 3D printing, and CNC machinery. Unlike traditional motors, stepper motor 1.6 do not require feedback systems to determine their position, making them simpler and more cost-effective for many applications. Their ability to be controlled via digital pulses makes them highly compatible with modern electronic systems, bridging the gap between mechanical movement and digital control seamlessly.

There are several types of stepper motor 1.6, each suited to different applications and performance requirements. The most common types include permanent magnet, variable reluctance, and hybrid stepper motors. Permanent magnet stepper motors utilize a permanent magnet rotor and are known for their simplicity and cost-effectiveness, making them ideal for low-torque applications. Variable reluctance stepper motors, on the other hand, do not use magnets; instead, they rely on the principle of magnetic reluctance, which allows for rapid stepping rates. Hybrid stepper motors combine the features of both permanent magnet and variable reluctance motors, providing higher performance, greater torque, and finer step resolution. The choice of stepper motor 1.6 depends largely on the specific requirements of the application, such as torque, speed, and precision needs.

stepper motor 1.6 offer a range of functions and features that make them indispensable in precision applications. One of their primary functions is to convert digital pulses into precise mechanical motion, allowing for accurate control over position, speed, and acceleration. Key features of stepper motor 1.6 include high torque at low speeds, excellent low-speed stability, and the ability to hold positions without the need for power. This makes them particularly useful in applications where precise positioning is critical, such as in 3D printing and CNC machines. Additionally, stepper motor 1.6 are known for their durability and reliability, often requiring less maintenance than other motor types due to their simple construction and lack of brushes.

The construction of stepper motor 1.6 involves the use of various materials to optimize performance and durability. The rotor is typically made from high-quality ferromagnetic materials, which enhance magnetic performance and efficiency. The stator, which houses the windings, is often constructed from laminated steel to minimize eddy current losses. Copper windings are used extensively in stepper motor 1.6 due to their excellent electrical conductivity, which ensures efficient conversion of electrical energy into mechanical motion. The materials used in stepper motor 1.6 are chosen to provide a balance between performance, durability, and cost, ensuring reliable operation in demanding environments. Advances in material science continue to drive improvements in motor efficiency and performance.

To use stepper motor 1.6 effectively, it is important to understand their operating principles and limitations. Proper selection of the motor type based on the application's torque, speed, and precision requirements is crucial. For optimal performance, stepper motor 1.6 should be driven with an appropriate driver that matches the motor's specifications, ensuring smooth and accurate operation. It is also important to consider the power supply voltage and current requirements to prevent overheating and ensure efficient operation. In applications requiring high precision, microstepping techniques can be employed to enhance resolution and smoothness of motion. Regular maintenance, such as checking connections and ensuring adequate cooling, can help prolong the life of stepper motor 1.6 and maintain their performance over time.

When selecting stepper motor 1.6 for your application, several factors must be considered to ensure optimal performance. The first consideration is the torque requirement, which determines the motor's ability to move or hold a load. Applications requiring high torque may benefit from hybrid stepper motors, while those needing lower torque might opt for permanent magnet types. Additionally, the operating environment plays a crucial role; for instance, motors used in harsh conditions should have robust construction and materials that resist wear and tear. It's also vital to consider the desired step resolution, as finer steps provide greater precision in control.

Understanding the specifications of stepper motor 1.6 is essential for making an informed choice. Key specifications include the step angle, which affects the resolution and smoothness of motion. Smaller step angles allow for more precise control, beneficial in applications like CNC machinery. The voltage and current ratings are also critical, as they determine the motor's power consumption and efficiency. Furthermore, the holding torque indicates the motor's ability to maintain its position when not in motion, which is particularly important in applications requiring stability and precision. Evaluating these specifications helps match the motor to the specific demands of the application.

stepper motor 1.6 are widely used across various industries due to their precise control capabilities. In the medical field, they are utilized in equipment such as infusion pumps and imaging devices, where accurate positioning is crucial. The automotive industry employs these motors in systems requiring reliable and repeatable motion, such as in electronic throttle control. In the consumer electronics sector, they are essential in devices like printers and cameras, providing precise movement for high-quality outputs. Each application requires careful consideration of the motor's specifications to ensure it meets the necessary performance criteria.

The main difference between stepper motor 1.6 and servo motors lies in their control mechanisms. Stepper motors operate in discrete steps and do not require feedback systems for position control, making them simpler and often more cost-effective. Servo motors, however, rely on feedback systems to achieve precise positioning, allowing for smoother motion and higher speeds.

To increase the precision of stepper motor 1.6, microstepping techniques can be employed, which divide each full step into smaller increments. This enhances resolution and smoothness, improving the motor's ability to achieve finer movements. Additionally, ensuring optimal driver settings and minimizing mechanical backlash can contribute to increased precision.

While stepper motor 1.6 excel in applications requiring precision at low speeds, they can be used in high-speed scenarios by selecting the appropriate motor type and driver. Hybrid stepper motors often offer better performance at higher speeds due to their design. However, it's important to ensure the motor's specifications align with the speed requirements to avoid performance issues.

Maintenance for stepper motor 1.6 typically involves regular checks of electrical connections and ensuring adequate cooling to prevent overheating. Unlike brushed motors, stepper motors do not have brushes that wear down, reducing maintenance needs. However, periodic inspection of mechanical components and lubrication may be required to maintain optimal performance.

Yes, stepper motor 1.6 can be used in battery-operated devices, provided the motor's power consumption is compatible with the device's battery capacity. Selecting motors with lower voltage and current requirements can help optimize battery life. Additionally, efficient driver circuits can further reduce power consumption, making them suitable for portable applications.