All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(663 products available)

To accommodate different needs and applications, the steel flat bar bender for sale comes in various types.

Manual Steel Flat Bar Bender

It is a traditional machine that relies on human power to bend steel bars. It usually consists of a sturdy frame with a bending beam or arm attached. Users can position the steel flat bar under the bending arm and apply force to the arm to bend the bar to the desired angle. Manual steel flat bar benders are affordable options for businesses that do not need to do a lot of steel bending.

Pneumatic Steel Flat Bar Bender

It is a machine that uses compressed air to bend steel flat bars. It will typically have a bending mechanism powered by a pneumatic cylinder. The cylinder receives compressed air, leading to the bending of the steel bar. This machine is suitable for operations that require frequent or continuous steel bar bending.

Hydraulic Steel Flat Bar Bender

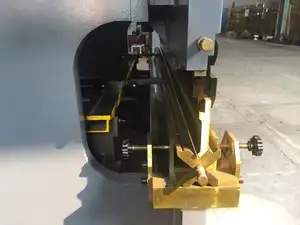

It is a bender that uses hydraulic power to bend steel flat bars. It usually has a hydraulic pump, a bending mechanism, and a control system. The hydraulic pump provides the power for bending motion. Users can control the angle and force of bending through the control system. Because of their high capacity, hydraulic steel flat bar benders are appropriate for heavy use like construction projects and metal fabrication.

CNC Steel Flat Bar Bender

This machine has a computer-controlled bending system that allows users to bend steel bars precisely according to predetermined programs. The machine has a bending mechanism controlled by a CNC (computer numerical control) system. This gives users flexibility and accuracy in their manufacturing processes. Therefore, CNC steel flat bar benders are ideal for complex and high-volume production requirements.

The performance of steel flat bar bender machines depend on their specifications. The machine also needs maintenance to keep bending bars of different thicknesses.

Because they have simple parts, all steel flat bar bending machines need minimal maintenance. Here are the maintenance tips:

The steel flat bar bender is widely used in industrial workshops, construction sites, metal factories, and more. Here are some usage scenarios of the steel flat bar bender.

Fabrication shops

In metal fabrication shops, the steel flat bar bender helps create different metal parts. It is useful for bending steel flat bars into brackets, frames, and signposts. The bender allows fabricators to get accurate bends at various angles. It improves productivity in the shop when making several parts with many steel flat bars.

Construction sites

Steel flat bar benders are helpful on construction sites. They help bend steel flat bars used as support beams, steel brackets, and door frames. The bending machines allow construction workers to change the shape of steel parts to fit projects. Using the bender reduces the need to transport steel flat bars to outside shops for bending.

Metal work schools

In technical schools for metalworking, steel flat bar benders are essential for training students. The benders help students learn how to make brackets, frames, and metal gates. Students also get hands-on experience when using the bender to create their designs. This will prepare them for future jobs in the fabrication industry.

Aerospace and automotive

Steel flat bar benders help make metal parts in the aerospace and automotive industries. They help bend steel bars into mounting brackets and chassis components. The machines help the manufacturers get accurate bends in different geometries. Using the bender improves production efficiency and product quality.

Marine industry

In the marine industry, steel flat bar benders are commonly used when making metal parts for boats and ships. They help bend the steel bars into shapes like frames and supports used in the hull. The flat bar benders ensure the marine structures made are strong and durable.

Mobility and automation industry

Flat bar steel benders help manufacturers produce parts in the mobility and automation industry. They bend steel bars into tracks, conveyor systems, and frames. These machines enable manufacturers to get precise bends. This promotes speed and accuracy in the production processes.

Steel flat bar bender is a big investment for business buyers. They will look for the things that can impact the overall efficiency of their business.

Production Needs:

Evaluate the specific needs of the production line, such as commonly used materials, thicknesses, widths, etc. Choose a machine whose bending capacity meets the production needs to avoid purchasing an over/under-targeted machine.

Workforce Skills:

Consider the skill level of the workforce. If the operator has limited experience with machinery, look for a steel flat bar bender with user-friendly controls and straightforward setup to minimize the learning curve and ensure smooth operation.

Production Volume:

Determine the required machine's production volume and frequency based on this typically. If dealing with high production volume and frequent bending operations, consider investing in a steel flat bar bender that offers automation features for increased efficiency and productivity.

Floor Space:

Analyze the available floor space and determine the machine's footprint. Ensure the dimensions of the chosen steel flat bar bender fit well within the allocated space and allows for proper workflow and equipment arrangement.

Budget Constraints:

When selecting the steel flat bar bender, consider the overall budget and resource allocation for the entire production setup. Evaluate the machine's cost in the context of the overall budget to ensure a balanced investment across all critical production equipment.

Q1: What types of bends can a steel flat bar bender make?

A1: A steel flat bar bender can form various bends, such as circular, square, rectangular, and V-shaped bends. The exact capabilities depend on the type and model of the bender.

Q2: Is it difficult to operate a steel flat bar bender?

A2: With the proper training and instruction, operating a flat bar bender is not difficult. Many machines have automated features that make the bending process easier and faster.

Q3: Can a steel flat bar bender accommodate different thicknesses of steel?

A3: Yes, most benders can handle various steel thicknesses. However, there are limits depending on the size and capacity of the machine.

Q4: Is It necessary to heat the steel before bending it?

A4: It is not always required to heat the steel before bending. Some machines can bend cold steel; however, certain thicknesses may need pre-heating for better results.