All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(1599 products available)

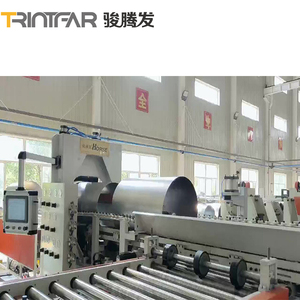

steel barrel drum make machin are vital parts of packaging since they provide consistent containers for different products in several sectors. Designed to hold and move a variety of goods, from liquids and powders to solids and hazardous items, these sturdy containers are made of steel, plastic, and fiber. Their dependability for supply chains and logistics comes from their strong building and adaptability. Innovations in the design and functioning of steel barrel drum make machin keep developing as the demand for safe and effective packaging solutions increases, therefore addressing both environmental and pragmatic issues.

The market provides a wide range of steel barrel drum make machin, each suited to particular uses and needs. Among common forms are fiber barrels, plastic pails, and steel drums. Often used for shipping chemicals and dangerous items, steel drums are known for their robustness. Food goods and other non-toxic compounds fit plastic pails, which are lightweight and corrosion-resistant. Made from compressed paper, fiber barrels are a green choice for moving powder and dry commodities. Every kind of steel barrel drum make machin is designed with particular elements to guarantee the best performance and safety during transportation and storage.

steel barrel drum make machin has several purposes and characteristics that improve its value in logistics and packaging. Their main purpose is to give different products safe transit and storage so as to protect them from physical harm and infection. Important characteristics that help to maximize space use and simple handling are airtight sealing, stackable designs, and strengthened handles. Stackable designs maximize storage capacity; airtight sealing stops leaks and protects the integrity of the contents. Strong reinforced handles guarantee easy and secure mobility. Furthermore, fit for a broad spectrum of industrial uses are various steel barrel drum make machin, which are made to tolerate high temperatures and pressures.

Building steel barrel drum make machin calls for the use of several materials, each chosen for their particular qualities and fit for a certain use. The main materials used, steel, plastic, and fiber, have different benefits. Perfect for heavy-duty uses, steel is appreciated for its strength and endurance. Appropriate for liquid and solid materials, plastic offers flexibility and corrosion resistance. Perfect for dry goods, sustainable alternative fiber is lightweight and biodegradable. The material used affects the weight, resilience, and environmental impact of the container, so producers can customize steel barrel drum make machin to satisfy particular industry criteria and consumer expectations.

Using steel barrel drum make machin successfully depends on choosing the suitable kind depending on the kind and volume of the materials. Make sure the container fits the chemical characteristics of the product and storage circumstances to stop degradation or contamination. Make the best use of features such as stackable designs and airtight closures to maximize transportation and storage effectiveness. Regular inspection and cleaning are part of proper maintenance that helps to extend the lifetime of steel barrel drum make machin and guarantee user safety. Minimizing hazards and guaranteeing regulatory compliance depends on teaching staff members in industrial environments about handling techniques and safety procedures.

Several elements have to be taken into account while choosing the suitable steel barrel drum make machin for packaging and logistics to guarantee the best performance and economy. The nature of the goods being transported or kept determines the kind of container used. For example, whilst plastic pails are appropriate for food goods because of their corrosion resistance, steel drums are preferable for hazardous compounds because of their strength. To stop any negative reactions, one must evaluate the chemical compatibility of the container with its contents. Furthermore, external factors, such as humidity and temperature, could compromise the integrity of the steel barrel drum make machin. Aligning the material and design of the container with the particular requirements of the application will help to improve operation safety and efficiency.

Selecting the appropriate steel barrel drum make machin depends much on size and capability. The container has to hold the product's capacity without sacrificing structural integrity or available space. Larger drums or barrels are best for bulk storage; smaller pails will do for limited quantities. Furthermore important are transportation and handling convenience; characteristics like stackable designs and stronger handles considerably improve maneuverability and storage efficiency. Moreover, the choice process should be guided by the certifications and regulations applicable to the sector, thereby guaranteeing compliance and safety. Examining these elements closely can help make wise judgments that maximize the packing approach.

As sustainability takes the front stage in packaging, one should take steel barrel drum make machin environmental impact into account. Choosing recyclable or biodegradable containers helps operations have less of an impact on the environment. For example, whilst fiber barrels provide compostable choices, steel drums are quite recyclable. Verifying company sustainability claims and making sure the manufacturing techniques follow environmentally friendly guidelines is absolutely essential. Including sustainable options in packaging solutions not only satisfies customer needs but also helps to support environmental protection projects.

The chemical characteristics, weight, and environmental surroundings of the product affect the steel barrel drum make machin material choice. The durability of steel is preferred; plastic is flexible, and fiber is sustainable. Every material has particular benefits that fit distinct packaging requirements.

Indeed, some forms of steel barrel drum make machin, such as steel drums, are used to securely move dangerous goods. Their strong building and sealing systems guarantee conformity with safety rules by offering defense against leaks and pollution.

Labels, logos, and colors let many [keywords] be altered to improve brand visibility. Different materials and designs of the container affect customizing choices, which gives companies chances to set their products apart on the market.

The steel barrel drum make machin's size directly affects transportation logistics and storage capacity. While smaller containers provide flexibility and simplicity of transportation, larger containers optimize storage and may call for specialist handling tools. One should strike a mix between size and pragmatic factors.

Using sustainable materials and techniques, eco-friendly steel barrel drum make machin aids in lowering environmental effects. They can help to meet customer tastes for green products, improve brand reputation, and support general waste reduction initiatives. Selecting environmentally sustainable solutions fits with the objectives of world sustainability.