(40 products available)

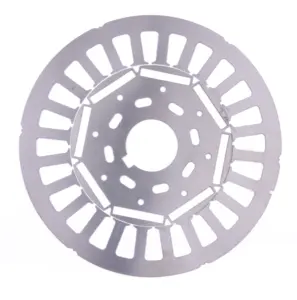

Staters are vital components in electric tools as they help in the generation of electromotive force. There are different types of stator makita, depending on the electric tool in which they are found.

Stator for Corded and Cordless Tools

A stator used in corded tools is designed for constant AC input, while the one used in cordless tools works on DC, which is stored in batteries. This mechanism gives the tool power to operate, especially wirelessly. With continuous usage, these stators are known to become worn out, needing replacement. For instance, an electric drill, saws, and impact drivers utilize stators to generate torque.

Stator for Brushless Motors

More recent makita tools have incorporated a brushless motor, and this means a more advanced stator. Unlike the traditional motor with brushes, there is no friction involved in producing energy. Brushless motors are more effective, need less maintenance, and, more importantly, have higher operating times, increasing tool longevity. In addition, the stator's structure in brushless motors is complicated, with several windings.

Stator for Generators

Makita generators use a specific type of stator for producing electricity. Electric generators, much like other electric motors, operate on the electromagnetic induction principle. Stators are thus used in the coils that produce voltage when the generator is turned on. As a result, these stators are created to withstand much more than other operating elements. It is due to this reason that they are constructed with long-lasting materials.

Stator for Different Equipment

Other equipment such as angle grinders, nail guns, and jackhammers also have unique stators. Each of these tools will be designed based on power needs, operational modes, and construction elements. Irrespective of the equipment one is using, it is important that they buy an accurate replacement stator if needed. Using a different stator may not only cause efficiency but may also lead to potential safety hazards.

Some of the key features of stator parts are as below:

Durability

Usually, a stator is made of metal, specifically copper wire and silicon steel. Some premium quality stator components are made of premium grade materials.

Precision Engineering

Stators are therefore carefully designed so that efficiency is increased as well as optimal performance.

Heat Resistance

This is particularly appropriate for tools constantly used for high load carrying. These stators have been designed to resist extreme temperatures.

Compatibility

A key aspect concerning stators is their compatibility with certain tools. Refer to the model number of the tool in which the replacement part will be fitted.

Ease of Installation

There are stators that are designed with installation simplicity in mind. This enables one to do DIY replacements comfortably.

Know the model of Stotor that one has to change. Unplug the machine or remove the battery for corded tools. Open housing with a screwdriver. Remove the old stator carefully after noting how wires were connected. Put the new stator in place and connect wires as they were attached to the previous one. Close the housing and plug in the machine or put in the battery. Run the machine for a short period to check correct functioning.

Power Tools

Makita, a renowned global company, produces electric drills, saws, and grinders for use in both home and industrial settings. The stator, for instance, in these drills generates electromagnetic fields with the armature and rotor interacting with it to produce voltage, energy, and, ultimately, torque. This increases drill bits and blades operation in saws and grinders.

Outdoor Power Equipment

Aside from power tools, Makita also produces outdoor equipment such as trimmers, blowers, grass cutters, and hedge cutters. Strong stator windings assist electric motors in sustaining operation power and keeping them efficient.

Generators

Further, Makita also makes portable generators. A stator is a very crucial part of the generator's working mechanism because it helps to generate AC. The AC is then converted to DC, which is useful for powering many household electrical appliances.

Elevators

Also, in other electromechanical equipment, stators are used to control the efficiency and safety of the equipment. For example, electric hoist stators maintain load control over and reduce the chances of overheat. In addition, their use in worker safety comprises quality materials.

Industrial Machines

In manufacturing facilities, electric motors, therefore, have stators for driving machinery used in a mechanical operation. These stators need to be very durable. Any failure can result in dangerous situations guaranteed by Makita's insist on premium materials and precision engineering. They can withstand intense and prolonged use and enhance workplace safety.

The following points should be considered when buying stator parts:

Model Compatibility

This is because every stator part is designed for a certain model. It is wise to refer to the manual of the tool or the tag on the tool in order to know the model number. Also, every stator sold online will have a model number on the description. Every model number must match perfectly.

Quality Materials

Buy a stator that will be made from quality materials as it will have a longer life. Materials that are easily damaged include silicon steel for the core and copper wire. Premium quality has strong copper and silicon steel for windings.

OEM vs. Aftermarket

These stators are manufactured by Makita for their tools. They offer a guarantee of perfect fit and functionality. Aftermarket stators are manufactured by other companies. Some may be of superior quality, while others may not be. Research to find customer feedback in order to know the quality of aftermarket parts.

Warranty

Good manufacturers always offer a warranty. It indicates that the product has been tested and has satisfied quality. Also, understand the warranty terms. If the material has a warranty, it means it will be replaced at no charge when needed due to defects in workmanship.

Installation

Think about how easy is the installation. Some parts come with installation guides and videos. If one has to hire a mechanic for the stator replacement, then choose a part that comes with easy installation. A complicated part will add more labor cost.

Reviews

Always read customer reviews before buying a product. Positive reviews mean the product is of quality. Look for reviews that offer feedback on material quality, durability, and fit.

A1. Symptoms of a bad stator include overheating, a burning smell, and abnormal sounds. In addition, the tool may not function properly, operate at low power, or get intermittent power. In some cases, users may experience smoke or sparks from the engine. Stators are sometimes accompanied by failure of other components.

A2. Stators are usually lasting for several years if the part is mostly in low usage. However, in heavy use, it may take a couple of years or less. In addition, quality materials will ensure longer life, and proper maintenance will also extend the life of the part. The user must be able to avoid overheating.

A3. Aftermarket accessories may be cheaper. Sometimes, they are even better if sourced from a reputable manufacturer using the latest technology. While managers may consider them convenient, they are still efficiency-enhancing instruments whose failure can put an operator at risk.

A4. This is known to fail in some typical ways: overheating, burning smell, abnormal sounds, power loss, and in some cases smoke or sparks. Occasionally, users may find that their tools fail to function as expected. A failing stator may cause damage to other components.

A5. Changing stator parts can be done easily, especially in parts with manuals and videos. Some jobs are complicated and require the help of an expert. It also depends on experience and tools available. Some stator placements require special tools.