Types of SPT test of soil

In geotechnical engineering, the SPT (Standard Penetration Test) is the most widely used in-situ soil testing method to identify the soil strata and ascertain the relative density of granular soil such as sand and the unconfined compressive strength of cohesive soil, which describes the behavior of rocks.

The SPT soil test is generally performed when engineers need to understand the physical and geotechnical properties of the soil at great depths to design different types of building foundations, such as shallow foundations, which include strip, raft, and slab foundations, as well as deep foundations like pile foundations.

- The DTH hammer produces a soft blow during the SPT, which determines the resistance the soil exerts when a split tube insertion is performed. The first 12 inches of the tube is called the '' Seating Blows,''' and the number of blows performed to penetrate the next 12 inches of the tube is called the total SPT N value.

- Sand: As mentioned, the SPT test is the most common test performed in sandy soil. Resistance is encountered when the split tube is pushed through the sand, which is its natural density.

- Cohesive Soil: Cohesive soils are described as slimy materials that exhibit plasticity and depend on water content. Examples are clay and silt. Cohesive soils require more energy to overcome resistance and are considered structured.

- Rock: When the drill pipe is driven into bedrock, little resistance is offered, and the number of blows required to penetrate the rock is minimal. Hence, the SPT is an economical way of determining subsurface rock formations.

- Foundation: After accurately determining the soil and rock strata, load-bearing capacity can be calculated. The number of blows in various soil types can give a geotechnical engineer an understanding of the soil's behavior when a load is applied to it. The engineer can then design a foundation to support the building or structure.

Specification and maintenance of SPT tests of soil

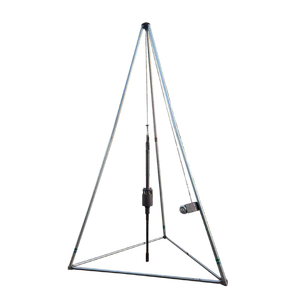

The standard penetration test is manufactured in different models and specifications. Here are some common specifications.

- Diameter: The SPT sampler consists of a tripartite tube with an external diameter of 5 cm (2 in) and an internal diameter of 2.5 cm (1 in).The diameter of the sampler can be varied to suit particular needs or specific ground investigation requirements.

- Length: The SPT sampler comprises a split tube of lengths of 2 m (6.5 ft) or 1 m (3.3 ft) and of 1 m (3.5 ft) sections respectively. The length of the tube can vary to accommodate particular depths.

- Weight: The split tube sampler weighs approximately 10 kg. The exact weight will depend on the material used in the construction of the sampler as well as the particular specifications of the sampler.

- Material: The sampler is pushed into the soil with a hammer weighing about 63.5kg falling a distance of 3.05m (10 ft), 20 times or until refusal is reached and the resistance of the soil is evaluated.

Proper maintenance of the SPT apparatus and equipment is vital to ensure continued reliable performance, which ensures the integrity of the ground investigated and successful consequent construction.

- Regular calibration: It is essential to ensure that the SPT apparatus is regularly and accurately calibrated.

- Cleaning after use: Geotechnical drilling rigs are often used to perform the standard penetration test. Standard penetration tests are often done with other tests or borings, such as cone penetration tests. Some geotechnical drilling rigs have dual-tube technology that allows for simultaneous standard penetration testing and soil sampling through the use of a second inner tube. There is a risk of cross-contamination if different soil samples are used on different soils simultaneously. Because of this, it is critical to ensure that all samples and test equipment are thoroughly cleaned after use. Soil and sediment are potentially harmful to equipment.

- Storage: Equipment used to perform the standard penetration test or any component of it should be stored in a dry and well-ventilated location. This is to prevent the formation of rust on metallic materials and other chemical reactions on other materials.

- Training: That used to perform tests or apparatus employed should be familiar with the equipment and its use. This is vital for the proper functioning of the equipment and its repair when necessary but also to help prolong the effective lifespan of the equipment.

Scenarios of spt test of soil

The SPT test has many applications, especially in construction and geotechnical engineering.

- Foundation design: When building infrastructure like bridges, homes, or commercial centers, engineers must decide what type of foundation to use and how deep they need to dig. They do this by finding the soil's strength, which the SPT blows counts reveal. Knowing how strong or weak the soil is saves money by allowing for simpler and cheaper foundations.

- Earthquake engineering: The SPT test shows if a soil area can sink during an earthquake, impacting how buildings resist shaking in quakes. Areas prone to earthquakes may need special foundations or construction methods based on SPT results. Quake-prone areas of Japan used the SPT to help design for better earthquake resistance.

- Dig depth in projects: Depth at which digs will occur in projects like excavations for basements, roadcuts, or trenching depends on SPT results as soil strength varies with depth. Knowing this soil strength variation helps set safe dig depths where weaker soils may require extra support or precautions.

- Hazard assessment: Areas where landslides are possible, especially during heavy rains, need hazard assessments based on SPT results. If the SPT shows the soil is at risk of sliding, more studies and monitoring should occur to prevent slide-related hazards. Cost-effective safety depends on land stability knowledge from SPT data.

- Choosing drill method: When drilling a well or borehole, the soil types and strengths revealed by SPT blows counts determine the best drilling method to use. Some soils require special techniques or equipment for safe, effective drilling. Selecting the proper drill based on SPT results maximizes performance and minimizes costs.

How to choose SPT test of soils

When purchasing SPT test of soil equipment or any soil testing apparatus, it is essential to look at various aspects like the quality assurance of the products, their compliance with international standards, and the supplier's commitment to after-sales support.

Businesses should ensure that the apparatuses have been manufactured according to the quality management systems. This is crucial since even the tiniest defect in soil testing equipment can lead to wrong interpretations of soil properties. Usually, soil testing apparatus suppliers will offer equipment that complies with internationally recognized standards. This means it is manufactured to fulfill specific criteria for quality and performance, which also includes accuracy and reliability.

Because these SPT testers are mostly used for business purposes, buyers should ensure that the suppliers provide installation and after-sales services. Good after-sales service will ensure that the end user gets the required support whenever needed. Buyers can also get customized solutions if they are offered a logistics service with a dedicated team ready to accommodate their requests.

Through the years, several studies have proven the importance of soil testing in construction. Customers purchasing SPT soil testers will likely be more interested in knowing how the material and quality affects the test results and how crucial it is for building strong infrastructures.

SPT test of soil Q&A

Q1: What are the benefits of dynamic cone penetrometer?

A1: Dynamic cone penetrometer has many benefits. Firstly, it is useful for estimating soil strength and resistance, which is crucial for assessing the stability and load-bearing capacity of soils. Secondly, it provides immediate results and enhances productivity on construction sites. Thirdly, it is cost-effective. Finally, it is versatile as it can be applied to a wide range of soil types and conditions.

Q2: What aspects of soil does the field test provide information about?

A2: The field test provides information about the composition, density, consistency, and cohesive properties of the soil. It also reveals the dynamic behavior of the soil under penetration conditions and its strength characteristics.

Q3: What are the trends in the SPT market?

A3: The soil penetration test market is heading toward the adoption of technology. The SPT test data is now being analyzed with the help of software. This provides more accurate results, and soil classification is easier.

Q4: What is the service life of the SPT hammer?

A4: The service life depends on the material it is made of and the frequency of its use. A sturdy metal SPT hammer with proper maintenance can last for decades, even with frequent use.

Q5: What is the sampling method used in the SPT test?

A5: The SPT test uses the split spoon sampling method. This involves taking samples of the soil by using split spoons. The soil is then used for further analysis and testing in the laboratory.