All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(577 products available)

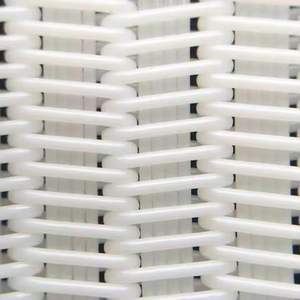

An important component of the papermaking machine is the spiral dryer fabric screen, which allows wet paper to be dried while the wet paper is present. Most screens for spiral dryers are made of synthetic fibers with a considerable opening area to allow dried air to pass through them. Their permeability to water is aided by this feature, which also quickens the dehydration of wet paper.

Industrial dryers are frequently supported by drying linens that strengthen the paper and produce polished surfaces. In any industry, dryer screens come in different styles to fit various specifications and may generally be categorized into the following:

Drying fabrics for spiral dryers typically come in various specifications to cater to different industries and applications. Here are some key dryer fabric screen specifications with maintenance tips:

Materials

Spiral dryer fabric screens may come in polyester, nylon, or other material options. Different materials need to be maintained differently. For instance, due to the good chemical resistance and high strength, polyester is the most widely used material. Therefore, users should apply proper maintenance to avoid fabric damage or accelerated fabric aging. For instance, they should avoid exposing themselves to harsh chemicals, strong UV lights, or high temperatures, which may require greater levels of fabric degradation and deterioration.

Mesh Size

The mesh size determines the size of the openings in the fabric, which affects the airflow and moisture removal. Maintaining the appropriate mesh size is crucial for the desired dryer fabric functionality. Consequently, users should regularly monitor and adjust the mesh size for optimum performance based on production goals. They should also avoid over-stretching or over-tightening the fabric, which can damage the mesh openings, leading to reduced airflow and moisture extraction efficiency.

Surface Treatment

Some spiral dryer fabrics have surface treatments or coatings to enhance performance or durability. Users should consider the surface treatment when maintaining the fabric. For instance, users should avoid using harsh chemicals or abrasive cleaning methods that degrade the surface treatment. They should also follow the recommended cleaning and maintenance procedures for their specific surface treatment type.

Operating Conditions

The operating temperature, humidity, and pressure in a spiral dryer fabric can affect the fabric's performance and lifespan. Therefore, users should regularly monitor operating conditions and not exceed the recommended parameters for fabric material and design. Otherwise, they may accelerate fabric wear and damage. Besides, they should insulate and protect the fabric from sources of heat or chemical degradation.

Accessories

Spiral dryer fabrics may require some accessories, like tensioning devices or fasteners, for proper installation and operation. Users should regularly check and maintain the accessories to ensure they are in good condition. They should also adjust and tighten them appropriately to avoid fabric sagging, excessive tension, or misalignment.

Spiral dryer fabrics are the backbone of various essential industries. Without them, the industries mentioned below would probably grind to a halt.

The following factors can affect the purchasing decision of a spiral drying fabric:

Mesh Size and Openness

Consider the mesh size and openness of the fabric. A larger mesh size may allow faster airflow and drying but can also impact product quality and control. Balance the need for throughput with the required product parameters.

Durability and Strength

Evaluate the durability and strength of the fabric. Select a material that can withstand the specific operating conditions of the drying process, including temperature, humidity, and any chemical exposure.

Cleaning and Maintenance

Consider the ease of cleaning and maintenance of the fabric. Choose a material and design that can be easily cleaned to maintain the hygienic and efficient operation of the drying system.

Cost-effectiveness

Consider the cost-effectiveness of the fabric. While the initial cost may be a factor, also consider the long-term performance, durability, and maintenance requirements to determine the overall cost-effectiveness of the material.

Supplier reputation and support

Finally, consider the supplier's reputation and support. Research potential suppliers and read reviews from other customers to ensure that the chosen supplier has a good track record of providing high-quality fabrics and responsive customer support.

Q1 What material is spiral dryer fabric made from?

A1 Spiral dryer fabric is made from polyester, pps, or a combination of both. They are suitable for high-temperature, high-pressure, and high-absorption scenarios. The most common material is polyester.

Q2 How do spiral dryer belts impact energy consumption?

A2 Spiral dryer belts are designed to reduce resistance and energy consumption. Their lightweight materials and optimized design allow for lower energy usage during operation, contributing to overall energy efficiency and cost savings in the drying process.

Q3 Can spiral dryer fabrics be repaired if damaged?

A3 Spiral dryer fabrics can be repaired if damaged, to a limited extent. Minor damages, such as small cuts or frayed edges, can be repaired through patching or stitching. However, addressing significant damages or structural issues is crucial, such as widespread wear or broken links, by replacing the fabric entirely to ensure optimal performance and avoid potential hazards.

Q4 Do spiral dryer fabrics have a noise reduction feature?

A4 Spiral dryer fabrics inherently possess noise reduction features due to their design and materials. They can absorb and dampen the noise generated during drying processes, such as vibrating, tapping, or rubbing, thereby reducing the noise pollution impact on workplaces or surrounding environments.