All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5440 products available)

Straight Spiral Bevel Gears

The teeth on these gears are straight and angled to the gear's cone shape. The angle of the teeth is constant from one end of the gear to the other. This type of bevel gear works well at transmitting motion between shafts at 90 degrees to each other, though with lessened efficiency compared to other types. Straight bevel gears experience less manufacturing complication and are easier to fit due to their simple design. However, their performance shows more noise levels and a reduced lifespan because of the slipping that takes place when under heavy loads.

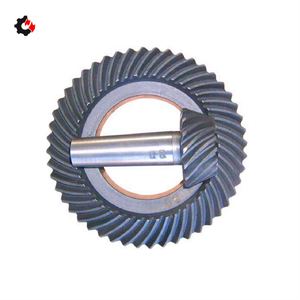

Spiral Gears

Unlike straight bevel gears, spiral bevel gears have slopes bitten into them, which makes it possible for them to mesh at an angle more quietly and smoothly. This design results in better contact between gear teeth, allowing for superior strength and the ability to handle more weight. Moreover, the gradual engage of the teeth reduces backlash, leading to improved precision in applications that require tight tolerances. Bevel gears are ideal for transmitting motion between non-parallel shafts, including at right angles and at larger angles. In contrast, straight spiral bevel gears work well at right angles only.

Crowned Spiral Bevel Gears

Crowned gears also have their teeth twisted, but only the center part of the gear tooth is designed to have a crown shape. With crowned bevel gears, the teeth are slightly curved towards the tip. For crowned bevel gears, the curvature of the teeth also contributes to the effective engagement of the gear teeth, resulting in smooth and quiet gear movement. The crown shape helps to improve the gear meshing alignment, reducing any misalignments that might have been present. Crowned spiral bevel gears are commonly used in applications where shaft misalignment is a possibility, for example, in some automotive differentials or industrial machinery whose shafts might not always perfectly align.

Conical Pinion Angle Spiral Bevel G

Cation Similar to other spiral bevel gears, conical pinion angle spiral bevel gears feature teeth that are inclined in both a helical direction and towards the small end cone shape pinion. This gear is primarily responsible for transmitting motion from the pinion or drive shaft to the larger conical gear, often at a 90-degree angle. The conical shape of the pinion helps to facilitate smooth movement between the two gears even under heavy loads. These types of gears are widely utilized in automobile drivetrains, such as differentials, where power needs to be distributed effectively between shafts.

Automotive Industry

One of the major uses of spiral bevel gears is in the automotive world. For example, differentials use the gears in the drive system, which allow power to be split smoothly between wheels. This gear helps the vehicle drive better, especially when going around corners or on different surfaces.

Machine Tools

In manufacturing equipment, these gears help pick up and control cutting tools. The smooth movement helps make tools more precise, improving how things are made. For example, in gear shapers, spiral bevel gears control how the cutter moves, which is key to shaping gears correctly.

Aerospace Systems

They work well because they are strong yet lightweight, which is ideal for flying safely. In aircraft control systems, for example, the smooth and precise operation of these gears makes the planes easier to steer. Even small errors can affect flight, so their use improves safety.

Marine Applications

Used in boats and ships for the driving and steering systems. The gears help transfer power smoothly from engines to propellers or rudders, allowing for better control of movement in water. The design also resists damage from being constantly submerged.

Industrial Machinery

Commonly found in heavy machines from factories, such as gearrings, turbines, and conveyor belts. Here, the gears help transfer power between different parts so everything runs together smoothly. Their ability to bear large loads while reducing friction is important for keeping machinery lasting a long time while working hard.

Construction Equipment

Included in excavators, bulldozers, and other vehicles used for building things. Just like in industrial machinery, these gears help different parts move together under tough working conditions on a construction site. Spiral bevel gears enable the precision and toughness needed to last through huge forces and outdoor environments.

Preparing the Gear

The first step in the installation preparation phase is ensuring that the bevel gears to be installed have all the required components in place. The required tools and materials for this process include hand tools, lubricant or gear oil, suitable fastening devices such as a hammer or screw, a torque wrench, a dial caliper, and a few dial indicators.

Installing the Gear

With the prepared gear ready, the next steps towards installation include securing the pinion gear on the main shaft and securing the bevel gear to the driven shaft.

Gear Pairing

Once the two different gears are secure on their different shafts, the next step is to mesh the two gears together. At this stage, it is important to ensure that the correct gear ratio is obtained by using the right gear pair.

Shimming

After meshing the gears, shims must be inserted where necessary to adjust the spacing between the two gears properly. The aim is to obtain proper gear tooth contact across the gear surface.

Safety Check

Before, any operation is carried out on the installed gear set. The sets must be double-checked to ensure that they are working properly. Additionally, the lubrication must also be checked to ensure that the proper amount and type of lubrication have been applied to the sets.

The following is a list of actions that can help maintain bevel gears:

Regular Lubrication: Spiral bevel gears should be lubricated regularly, and the lubricant should be changed often. This will help reduce friction and wear on the gear teeth, increasing the gears' lifespan and keeping them working properly.

Proper Alignment: The gears should be aligned properly to reduce unnecessary load on some parts of the gear. Misalignment causes certain teeth to bear more load than others, leading to quick wear.

Load Monitoring:

The gear's workload should not exceed the gear's recommendations. Working those gears with high loads that exceed the manufacturer's recommendations will warp or break the gear teeth. In addition, over-spiraling spiral bevel gear sets will cause them to heat up and warp.

Periodic Inspections

A periodic inspection of the bevel gears should be done. Look at the gear teeth for any signs of wear or defects, and check the teeth's surface for pitting, scoring, flaking, or other visible signs of damage. Additionally, listen for any strange noises, such as grinding or clicking, that may signal problems. Monitor the gear's vibrations. Unusual vibrations could signal a problem. Look at the gear casing for any visible cracks or breakage. Any damage in the casing can lead to damage on the gears.

Contamination Prevention:

Keep contaminants such as dirt, grit, and metal shavings away from the gears. Bevel gears can be damaged by contaminants because the contaminants may either scratch the gear teeth or cause the teeth to wear out. The contamination can cause overheating and even oxidation.

Material Selection

Choosing the right material for the bevel gears is important to their forming a secure and long-lasting structure. Bevel gear sets are made of metal types, including stainless steel, carbon steel, and alloy steel, which are selected based on the gear's intended application, operational circumstances, and cost. These metals are chosen due to their superior strength and resistance to wear.

Heat Treatment

The metal is then hardened into the gears through a process known as heat treatment. The treatment is important because it enhances the gears' surface hardness, making them resistant to wear while also toughening the core to prevent cracking or breaking under extreme stress.

Precision Manufacturing

In the gear-cutting phase, a great level of precision must be adhered to when cutting the gear teeth by machine operators. For quality and safety purposes, the teeth must be cut to exact proportions with the appropriate spiral angle to ensure evaluated equal meshing for smooth operation. Otherwise, any small deviation will lead to unbalanced distribution of stress and strain, which will either cause some parts to wear out faster or lead to gear fracturing.

Balancing

Proper balancing of the bevel gears is important because, during operation, unbalanced gears create vibrations, which reduce the gears' structural integrity. In extreme cases, unbalanced gears can crack or break, posing a danger to machine operators. Thus, for quality and safety considerations, appropriate balancing is required.

Load Testing

The completed tensile spiral bevel gears should be subject to test the gears' strength and workability. The gears should be tested under loads greater than the gears' normal working load to see if the gear will fail under extreme working conditions. It is also important to test for noise, vibrations, heat, and any other possible factors that can lead to an unsafe working environment.

Surface Inspection:

Unsurprisingly, any surface flaw, no matter how tiny it is, can reduce the gear's strength and cause catastrophic failure. Thus, any surface imperfection is a great concern when discussing the safety of spiral bevel gears. For this reason, gears must be thoroughly checked for pitting, scoring, cracks, and other signs of surface deterioration.

A1. Bevel gears are used to transmit and change the direction of power and movement between intersecting shafts in machinery effectively.

A2. In particular, spiral gears tend to operate more smoothly and quietly than straight gears because of their angled teeth, which provide better contact and less slipping. This makes them suitable for high-load applications where strength and precision are key. On the other hand, straight gears are simpler in design and easier to manufacture, but they generate more noise and have lower capacity for carrying heavy loads.

A3. Crown gears function by providing misalignment tolerance through a specially designed tooth curvature that helps the gears maintain proper contact even when slight misalignments occur. This quality will enable smoother power transmission and wear reduction, making them ideal for applications where shafts may not remain perfectly aligned.

A4. Bevel gear quality and lifespan are impacted primarily by the materials from which they are made, their precision in manufacturing, and how safely and under what loads they are operated. Proper lubrication also plays a key role in reducing wear and friction, helping the gears to operate longer and more effectively.

A5. Longevity is increased through proper lubrication, load monitoring within rated limits, alignment checking, and regular inspections for wear, imbalance, and contamination. Keeping dirt, grime, and moisture out of the gears also ensures they remain clean to function effectively and safely.