(1377 products available)

SMT pick and place robot machines are vital components of modern automated PCB assembly lines. There are several types, including the following:

gantry pick and place machines

Gantry systems employ a horizontal post or bridge to support its moving elements. Products are mounted onto the stationary gantry beam while feeder trays are positioned below. The gantry will move left and right to expose different areas of the PCB for components to be placed. As a larger format machine, it works well for high volume as well as large and complex assemblies. Because of its size, there are multiple components within it that allow for MGFs to have higher throughput as well as accuracy. Usually, single or dual head with the ability to feature vision systems for extreme accuracy and speed, gantry systems can be; single-head, dual-head, sliding head, benchtop, inline, or independent.

Linear motor-driven machines

These pick and place machines utilize linear motors or belt systems to move the placement heads along specified axes. They are suitable for a range of production volumes, speeds, and accuracies, depending on specifications. Linear motor drives offer excellent speed and accuracy. However, as they have fewer moving parts, consequently, there will be less need for maintenance.

Stick, tray, and tape feeders

Different types of feeders present components to the placement head in varying formats. Tape feeders are by far the most popular, as they can accommodate all types of PC evening and the most advanced. They feature a very high placing cardinality. Stick feeders are typically for long components like connectors, and tray feeders are usually for irregularly shaped components.

Scara Robots

Selective Compliant Assembly Robot Arms, or SCARA robots, are a particular kind of pick-and-place robot. Characterized by its compliance in the Z-axis due to its jointed geometry, SCARA robots are a major choice due to its greater speed and precision. The jointed structure also endows it with the capability for vertical stacking operations, helping in placement duties amongst compact PCB layouts. Additionally, SCARA robots are more easily adaptable for integration with vision systems and custom tooling, further enhancing their flexibility and efficiency on the assembly line.

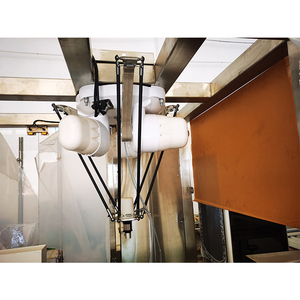

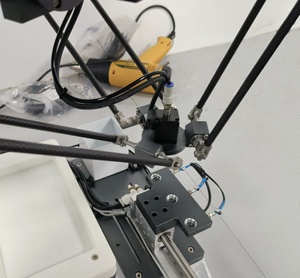

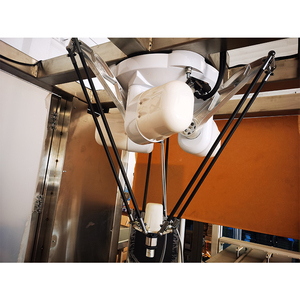

Delta robots

A specific type of pick and place robot, Delta robots are fast parallel-link robots. They are comprised of three arm segments in a triangular shape. It can move components to designated locations with high accuracy and speed. This makes it especially desirable in assembly applications requiring high precision and rapid deployment.

The invention of SMT pick and place robots brought a revolution to the electronics manufacturing industry. Their ability to enhance production lines has made them indispensable. Here are some uses of pick and place machines in various industries:

When selecting pick and place machines for sale, buyers should start by determining the types of PCBs they will be working with. Generally, some models of SMT robots are ideal for handling standard PCBs, while others are designed to manage complex configurations and large sizes.

Additionally, buyers should consider the load capacity and specifications of each SMT pick and place robot they intend to stock. Different models have distinct maximum weights and dimensions, so they can handle particular components. Therefore, it is important to choose robots with load capacities that match the components of different customers.

The speed and efficiency of the robots can also affect the production line's output. Buyers should evaluate the speed and overall efficiency of the SMT robots they want to purchase. They can do this by looking at the placement rates, cycle times, and feeding mechanisms of each robot. It would be best to opt for SMT robots with speeds that match typical production requirements.

Typically, recent models of pick and place robots come with automated feeders that make the replacing of components seamless. When making a choice, buyers should consider the types and availability of feeders that a robot supports. They should opt for the robots that are compatible with the feeders their customers typically use or those capable of easy changeovers.

Buyers should also evaluate the accuracy and precision of the robots they want to purchase. Generally, the placement accuracy of a robot will influence the quality of the resulting assembly. Buyers should look for robots with high precision ratings to meet the customers' expectations and avoid assemblies with low yield rates.

Moreover, buyers should consider the programming and integration capabilities of each pick and place robot. Buyers want machines that are easy to integrate into existing workflows. To achieve this, they should choose robots that have straightforward programming interfaces. Such robots have open architecture control systems. In addition, these robots will come with the necessary software tools.

Buyers should stock different models of SMT robots that vary in automation levels to suit distinct customer requirements. Some customers will look for a manual pick and place that will be easy on their budget. Others will need fully automated machines to streamline their processes. In this case, it would be best to purchase robots with varying levels of automation.

Finally, buyers should consider the maintenance and servicing requirements of the robots they want to choose. They should opt for robots that have straightforward maintenance routines and good availability of support service. This simplifies the robot's long-term upkeep and will eventually help the customer businesses run smoothly.

Q1: Are SMT pick and place machines difficult to program?

A1: No, modern SMT pick and place robots are designed to be user-friendly and easy to program. With intuitive graphical interfaces, operators can quickly create SMT pick and place programs that define how components will be picked and placed during the assembly process.

Q2: What are the trends in SMT pick and place technology?

A2: The trends are toward improving automation, increasing speed and accuracy, and enhancing machine intelligence. Automation is the main trend in SMT pick and place technology, with more robots replacing manual work. Machines are getting faster and more precise to meet industry demands. Machines are becoming smarter with artificial intelligence and machine learning for better component placement.

Q3: Can an SMT pick and place machine handle different types of components?

A3: Yes, SMT pick and place machines are designed to handle various components, including integrated circuits, resistors, capacitors, connectors, and other surface-mounted devices. They can manage components with different shapes, sizes, and weights.

Q4: Can an SMT pick and place machine be integrated into an existing production line?

A4: Yes, an SMT pick and place machine can be integrated into an existing production line. Most pick and place robots are designed to be compatible with different manufacturing setups. They can be incorporated with other machines and equipment to create a complete PCB assembly production line.