Types of Small Railway Wheels

Small railway wheels are essential components in railway systems, playing a crucial role in transportation on broad gauge, standard gauge, and meter railway tracks. These specialized wheels are primarily designed for transporting small goods and services with precision and efficiency. Each type offers unique properties suited for specific applications.

Cast Iron Wheels

Made from durable cast iron with excellent wear resistance, these wheels are predominantly used in freight railways.

Best for: Freight applications, durability

Limitations: Noise issues, brittle nature, poor for high-speed applications

Steel Wheels

Constructed from high-carbon steel, these are the most common type of railway wheels. They offer strength, durability, and superior load-bearing capacity.

Best for: Freight and passenger trains, general applications

Limitations: Require regular maintenance, susceptible to wear

Composite Wheels

Created from a combination of steel and other materials like aluminum, providing a blend of beneficial properties from different materials.

Best for: High-speed trains, passenger transport

Advantages: Lightweight, energy-efficient, superior braking properties

Plastic Wheels

Made from modern engineering plastics, offering low maintenance requirements and high corrosion resistance.

Best for: Industrial railways, light rail systems, urban areas

Advantages: Quiet operation, corrosion resistance

Aluminum Wheels

Lightweight with excellent corrosion resistance, making them suitable for various environmental conditions.

Best for: High-speed trains

Advantages: Reduced energy consumption, higher speed capabilities

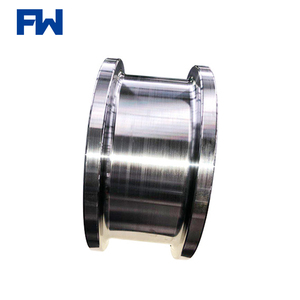

Welded Wheels

Constructed by welding together multiple smaller wheels, allowing for customization to specific requirements.

Best for: Heavy-haul railways, mining transportation

Advantages: High load-bearing capacity, customizable design

Expert Tip: When selecting a wheel type, consider not only the immediate application but also the operating environment and long-term maintenance requirements. For instance, while plastic wheels may seem cost-effective initially, they might not be suitable for high-load applications where steel or cast iron wheels would perform better.

Specifications and Maintenance of Small Railway Wheels

Understanding the key specifications and implementing proper maintenance protocols is crucial for ensuring optimal performance, safety, and longevity of small railway wheels. Below are the critical specifications and maintenance practices to consider:

| Specification | Description | Importance |

|---|---|---|

| Size | Range from 60 cm to 1.5 m in diameter | Affects speed, stability, and performance on tight curves |

| Material | Cast steel, forged steel, or specialized materials | Determines durability, weight, and corrosion resistance |

| Wheel Profile | Varies based on train type (freight, high-speed, passenger) | Impacts stability, noise levels, and riding comfort |

| Tread Pattern | Straight edges, tapered designs, or grooved designs | Affects traction, noise generation, and wear resistance |

| Load Capacity | Maximum weight the wheel can safely support | Critical for safety and reliability during operation |

Essential Maintenance Practices

Consistent maintenance is vital for extending the service life of small railway wheels and ensuring safe operation. Here are the key maintenance practices:

Regular Inspection

Scheduled visual and technical inspections to identify signs of wear, cracks, or defects that could compromise safety and performance.

Frequency: Weekly to monthly, depending on usage intensity

Wheel Lathe Treatment

Process using specialized equipment to restore wheel profiles and dimensions by removing worn material and correcting irregularities on the wheel rim.

Frequency: As needed based on inspection results

Rail Grinding

Maintenance of track geometry to ensure optimal wheel-rail interaction, reducing wear and improving operational efficiency.

Frequency: Quarterly or as track conditions dictate

Condition Monitoring

Implementation of monitoring devices to track vibration, temperature, and wheel profile changes, allowing for predictive maintenance planning.

Advantages: Early problem detection, reduced downtime

Lubrication

Regular application of appropriate lubricants to wheelset axle bearings to minimize friction and wear, improving reliability and performance.

Frequency: Monthly or according to manufacturer specifications

Documentation

Detailed record-keeping of all maintenance activities, inspections, and replacements for compliance and future reference.

Benefits: Regulatory compliance, maintenance optimization

Maintenance Tip: Implementing an ultrasonic testing program for railway wheels can detect internal flaws that are not visible during standard inspections. This non-destructive testing method can prevent catastrophic failures by identifying subsurface cracks before they propagate to the surface.

How to Choose Small Railway Wheels

Selecting the appropriate small railway wheels is a critical decision that impacts safety, performance, and operational costs. This comprehensive guide outlines the key factors to consider when making your selection:

| Selection Factor | Considerations | Importance Level |

|---|---|---|

| Material | Steel offers durability and strength; composite materials provide weight reduction; specialized materials address specific environmental needs | Critical |

| Size and Dimension | Affects handling, stability, and load distribution; must match track gauge and operational requirements | Critical |

| Load Capacity | Must exceed maximum anticipated load with an appropriate safety margin (typically 15-20% above maximum load) | Critical |

| Maintenance Requirements | Consider frequency and complexity of maintenance needs based on operational resources and capabilities | High |

| Environmental Conditions | Account for temperature extremes, humidity, corrosion potential, and other environmental factors in the operating environment | High |

| Cost of Ownership | Evaluate initial purchase cost against long-term maintenance expenses and expected service life | Medium |

| Regulatory Compliance | Ensure wheels meet all applicable industry standards and regulatory requirements | Critical |

Selection Tip: When choosing between wheel materials, consider not only the immediate application but also future needs. For instance, while cast iron wheels might meet your current requirements and budget, steel wheels might offer better long-term value through extended service life and reduced maintenance, despite higher initial costs.

Important Safety Notice: Never compromise on quality or load capacity when selecting railway wheels. Always choose wheels with verified certifications and from reputable manufacturers. Underrated wheels can lead to catastrophic failures, potentially resulting in derailments and serious accidents.

How to DIY and Replace Small Railway Wheels

Replacing small railway wheels can be challenging but manageable with proper preparation, tools, and safety measures. This step-by-step guide will help you complete the replacement process efficiently and safely.

Essential Tools and Equipment

- Lubricant (appropriate for railway applications)

- Heavy-duty safety gloves

- Safety goggles or face shield

- New railway wheels (matching specifications of the originals)

- Adjustable wrench set

- Ball-peen hammer

- Hydraulic axle jack (rated for the weight of your train car)

- Sturdy wood blocks for support

- Wheel press (for pressed wheels) or appropriate installation tools

- Torque wrench (for precise bolt tightening)

Position the train on level track. Engage all parking brakes and place warning signs to alert personnel of maintenance work. Disconnect power sources and ensure the train cannot move during the procedure.

Position the hydraulic axle jack under the train near the wheelset requiring replacement. Raise the train slowly until the wheels are several inches above the track. Place sturdy wood blocks under the train frame as safety supports before removing pressure from the jack.

Depending on the wheel design: For bolted wheels, remove retaining bolts or nuts using the appropriate wrench. For press-fit wheels, carefully use a hammer with wooden blocks to protect the axle while removing the wheels. Document the original position and orientation of all components.

Clean all components thoroughly. Apply appropriate lubricant to relevant surfaces of both the wheel and axle to ensure smooth fitting. Align the new wheels carefully with the axle and install according to the wheel type: For bolted wheels, secure with bolts torqued to manufacturer specifications. For press-fit wheels, use a wheel press or carefully tap into place with a hammer and wooden block to protect surfaces.

Reposition the jack and slowly raise the train to remove the wood blocks. Gradually lower the train until the wheels make contact with the track. Remove the jack completely while verifying wheel alignment and proper seating on the track.

Perform a comprehensive visual inspection of the installation. Check for proper alignment, secure fasteners, and correct wheel spacing. Have a qualified railway technician or engineer inspect your work before returning the train to service. Conduct a slow-speed test run to verify proper operation and absence of unusual noises or vibrations.

Safety Tip: Never rely solely on hydraulic jacks when working under a train car. Always use sturdy wood blocks or purpose-built safety stands as secondary supports. Remember that railway components are exceptionally heavy - always use proper lifting techniques and never work alone when replacing railway wheels.

Warning: Railway wheel replacement should only be attempted by individuals with appropriate mechanical knowledge and experience. Improper installation can lead to serious safety hazards including derailment. If you're uncertain about any aspect of the process, consult a professional railway maintenance technician.

Frequently Asked Questions

Small railway wheels serve numerous purposes across various applications:

- Model Trains: Scale replicas for hobbyists and collectors

- Light Rail Systems: Urban transit networks requiring smaller, lighter components

- Maintenance-of-Way Vehicles: Specialized equipment for track inspection and repair

- Industrial Applications: Factory rail systems for moving materials and products

- Miniature Railways: Tourist attractions and recreational facilities

- Mining Operations: Underground transport systems with space constraints

- Specialized Freight: Transportation of specific goods on narrow-gauge railways

Effective maintenance of small railway wheels includes several key practices:

- Regular Inspections: Visual and technological assessments to identify wear, cracks, flat spots, and other defects

- Cleaning: Removal of debris, grease, and contaminants that could affect performance

- Condition Monitoring: Using specialized equipment to track wheel wear patterns and vibration characteristics

- Lubrication: Proper application of suitable lubricants to bearings and contact surfaces

- Profile Maintenance: Reshaping worn wheels using specialized lathes to restore optimal profile

- Replacement: Timely substitution of wheels that have reached wear limits or developed defects

- Track Maintenance: Ensuring track conditions don't cause accelerated wheel wear

The frequency of these maintenance activities depends on operating conditions, load factors, and usage intensity. For safety-critical applications, documentation of all maintenance activities is essential.

Small railway wheels are categorized based on their design characteristics and application requirements:

| Wheel Type | Characteristics | Primary Applications |

|---|---|---|

| Plain Wheels | Simple cylindrical design with minimal flange | Basic industrial applications, light-duty use |

| Flanged Wheels | Prominent flange for secure track guidance | Standard railway applications, curved tracks |

| Grooved Wheels | Channel in the tread to accommodate rail head or guide | Tram systems, embedded rail applications |

| Resilient Wheels | Rubber or polymer elements between hub and rim | Noise reduction, vibration damping, urban transit |

| Solid Wheels | One-piece construction for maximum strength | Heavy-duty applications, freight transport |

| Wheels with Inserts | Replaceable wear elements in the wheel design | High-wear environments, cost-effective maintenance |

Each wheel type is engineered to meet specific operational requirements, balancing factors like load capacity, wear resistance, noise generation, and maintenance needs. Selection should be based on a thorough analysis of the intended application.

Determining the appropriate wheel size involves several considerations:

- Track Gauge: Must match the distance between rails

- Load Requirements: Heavier loads typically require larger wheels

- Space Constraints: Available clearance for wheel diameter

- Speed Requirements: Higher speeds generally benefit from larger wheels

- Manufacturer Specifications: Always consult original equipment guidelines

For replacement purposes, measure the existing wheel diameter and check for any identifying markings or part numbers. When in doubt, consult with a railway equipment specialist to ensure proper sizing.

Railway wheel work requires strict adherence to safety protocols:

- Use Proper PPE: Heavy-duty gloves, steel-toed boots, eye protection

- Secure the Vehicle: Ensure the train or car cannot move during maintenance

- Use Reliable Support: Never rely solely on jacks; always use safety stands

- Follow Procedures: Adhere to manufacturer guidelines and industry standards

- Work with Partners: Never perform heavy lifting or wheel replacement alone

- Use Proper Tools: Employ tools designed for railway maintenance

- Verify Work: Have installations inspected by qualified personnel before use

Railway components are exceptionally heavy and operate under significant loads. Improper handling or installation can lead to serious injuries or equipment failures.