All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(67 products available)

Slab shoring formwork for concrete slab roofs is a temporary support system used during the construction of concrete slabs, particularly for ceilings or roofs. It serves two primary functions: forming and shoring. Forming refers to the creation of molds into which concrete is poured to shape the desired slab structure. Shoring, on the other hand, involves providing temporary vertical support to the concrete slab until it can support itself, which is crucial for ensuring safety and structural integrity during the construction process.

Concrete slab formwork is a crucial component in the construction industry. It comes in various types depending on the requirements of the construction project. Here are the types:

Timber Formwork

This type of formwork uses timber to create molds for pouring concrete. It is highly adjustable and reusable, making it popular for various construction projects. However, it requires skilled labor to assemble and disassemble, which can increase overall project costs.

Engineered Formwork System

The engineered formwork system comprises prefabricated components that ensure quick assembly and disassembly. This type of formwork is cost-effective for large construction projects due to its durability and structural integrity. It is also suitable for projects requiring precise and repetitive concrete shapes.

Steel Formwork

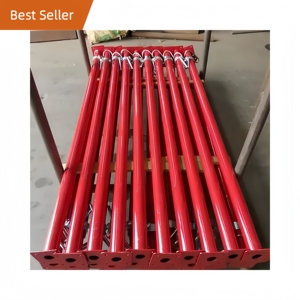

Steel formwork is used for concrete structures that require high strength and durability. The steel formwork is non-deformable, ensuring the concrete structure maintains its shape during curing. While the initial cost of steel formwork is high, its longevity and reusability make it a cost-effective solution for many construction projects.

Aluminum Formwork

This formwork uses aluminum materials to create molds for concrete slabs. Aluminum formwork is lightweight and easy to assemble, making it suitable for projects where time and labor costs are critical. It is commonly used in residential and low-rise construction projects.

Plastic Formwork

Plastic formwork is a modern construction technology that uses high-quality plastics to create molds for concrete. It is lightweight, water-resistant, and easy to clean, making it suitable for various construction projects. This formwork is particularly popular in schools, housing projects, and other infrastructure where speed and efficiency are essential.

Stay-in-place Formwork

This type of formwork remains in place after the concrete has cured. It includes reinforced concrete, steel, and composite formwork. Stay-in-place formwork provides additional structural elements and reduces shoring and decking labor, making it a cost-effective solution for specific construction projects.

Fiber Reinforced Plastic (FRP) Formwork

FRP formwork is a lightweight, durable, and corrosion-resistant alternative to traditional formwork materials. It is suitable for projects in harsh environments and offers a smooth finish to the concrete surface. However, it is less common due to its high initial cost and limited availability.

These formworks and shoring systems have features that enhance their function, making them ideal for temporary support during concrete slab casting. Here are the features and their functions:

Adjustability

These formworks are highly adjustable. They have features like telescopic props and adjustable brackets. The adjustability allows the formwork to be customized to fit different slab thicknesses and site conditions. This ensures optimum support for all concrete slabs, enhancing their functionality.

Modularity

The formwork and shoring systems are modular. They consist of interchangeable components. The modularity allows quick assembly and disassembly of concrete slab forms. This reduces construction time and increases efficiency, making it a preferred choice among contractors.

Heavy Load Capacity

The slab formwork shoring systems are designed to support heavy loads. They are constructed with high-strength materials, such as steel and engineered wood. The high load capacity ensures structural stability during the curing process of the concrete slabs, resulting in durable and reliable concrete slabs.

Easy Assembly and Disassembly

These formwork and shoring systems are designed to be easily assembled and disassembled. They have basic components and are equipped with simple hardware, such as clamps and bolts. This feature allows for quick setup and takedown, reducing labor costs and time.

Enhanced Safety Features

Slab formwork and shoring systems incorporate various safety features. They have robust locking mechanisms, guardrails, and anti-slip platforms. The enhanced safety features minimize the risk of accidents and ensure a safe working environment for construction personnel.

Durability

These systems are constructed with high-quality materials. They are subjected to rigorous engineering tests. This ensures they withstand harsh conditions and repeated use. Their durability makes them a long-term investment for contractors, as they can be used in multiple projects.

Compatibility

Shoring and formwork are compatible with various shoring systems, such as beam and acrow shoring. The compatibility allows for the integration of different systems, providing flexible support solutions. This is especially important in complex construction projects requiring customized support.

Shoring formwork is applied in several scenarios, including:

Supporting Structural Elements

Shoring formwork is used to support existing structural elements like beams, columns, and walls. This is done during construction activities to ensure these elements remain stable and secure. Formwork shoring provides temporary support for loads transferred to the ground.

Heavy Decks and Slabs

Shoring formwork is used in concrete decks and slabs with heavy reinforcement. This includes post-tensioned slabs and those with high concrete strength. Heavy slabs require additional support to enable proper curing and concrete pouring.

High-Rise Construction

In high-rise building construction, formwork shoring provides temporary support to columns, walls, and slabs. This is done for multiple floors during construction. The shoring formwork system allows the safe and efficient construction of tall structures.

Bridge Construction and Repair

Shoring formwork is used in the construction and maintenance of bridges. It supports bridge decks, girders, and other structural elements. The formwork system allows accurate alignment and positioning of bridge components during construction.

Below-Grade Construction

Shoring formwork is used in constructing basements and underground parking structures. It supports walls, ceilings, and other structural elements. The formwork system resists soil pressure and allows safe excavation.

Heavy Industrial Facilities

Formwork shoring is used in constructing industrial facilities like power plants, steel mills, and manufacturing plants. It provides support for large concrete structures such as chimneys, silos, and water retaining structures.

Specialized Applications

Shoring formwork can also be used in specialized applications such as lifting, jacking, and sliding operations. It supports heavy loads during the lifting and sliding of structural elements into position.

The factors below should be considered when choosing the right slab shore for a specific construction project:

Load Requirements

The primary consideration is the load that will be supported. This includes the weight of wet concrete, construction materials, and workers, as well as any environmental loads (wind, rain, etc.). Higher loads may require more robust materials or designs, such as heavy-duty steel shores.

Span Lengths

Consider the length of the spans between supports. Longer spans may necessitate stronger shores or a more complex system to distribute the load effectively. For example, aluminum shores are suitable for shorter spans due to their light weight and ease of handling, while steel shores can support longer spans due to their strength.

Height of Formwork

The height of the formwork will influence the type of shore to use. Taller formwork may require more stable and robust shoring solutions, such as high-capacity hydraulic shores or telescopic steel props, to ensure stability and safety during the construction process.

Type of Concrete Structure

The type of concrete structure being constructed (slab, beam, arch, etc.) will influence the shoring requirements. For example, shoring for slab construction may differ from that for beam or arch construction, necessitating different shore designs or materials.

Environmental Conditions

Consider the environmental conditions at the construction site. If the site is exposed to high winds, rain, or other environmental elements, more robust shores may be required to withstand these conditions. Additionally, if the site has a high water table, shores that can withstand wet conditions may be necessary.

Material Availability and Cost

Availability and cost of materials can also influence the choice of shores. Some materials may be more readily available or cost-effective in certain regions, influencing the overall cost of the construction project. For instance, wood may be more readily available and cheaper in some regions compared to steel or aluminum.

Labor Skills

The skills and experience of the construction workforce can influence the choice of shores. Some shoring systems may require specialized skills for installation and dismantling, while others may be more straightforward and require basic construction skills.

Q1: What is the purpose of slab shoring?

A1: The primary purpose of slab shoring is to support concrete slabs during construction to ensure the safety of workers and structural integrity of the slab. In addition, shoring transfers the weight of the slab to the ground so that the concrete can set and cure properly.

Q2: How much weight can shore props support?

A2: The weight that shore props can support varies depending on the type and material. For instance, galvanized steel props can support up to 25 KN - 30 KN. However, double tube steel props can support up to 45 KN - 50 KN. The load capacity of the prop determines the thickness of the concrete slab it can support.

Q3: What is the difference between formwork and shore?

A3: Formwork is a temporary structure that supports wet concrete until it's cured and hardened. Shores, on the other hand, are used to support existing loads in structural members like beams, walls, and slabs. Additionally, shoring props can be used to replace structural members under emergency situations.

Q4: What is the ideal material for shore props?

A4: The ideal material for shore props should be able to withstand harsh construction conditions. As such, galvanized steel is the best material for shore props. Steel is capable of withstanding high compressive strength and harsh weather conditions. In addition, the steel shore prop has a long lifespan and is reusable.