All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2830 products available)

Sintered plastic filters are porous filters made of powdered plastic that has been heated above its melting point and cooled to form a solid filtering medium. Sintered plastic filters are highly versatile and can be used in a variety of industries for several applications. Several types of filters can be classified based on their structure and flow direction.

The specifications of the sintered filter will vary depending on the type and application. The following are some common specifications:

It is important to keep in mind that different types of sintered filters will have other specifications. Therefore, they will be suitable for diverse applications. When choosing the right filter it is essential to consider the material, pore size, dimension, temperature range, and other characteristics. This will ensure that it is appropriate for the intended use or application.

The maintenance of sintered filters is essential so that they can perform well and have a long lifespan. The following are some of the maintenance tips for these filters:

Industrial liquid filtration

Many industries create a lot of liquids as byproducts. Nonetheless, before discarding these liquids, companies must first filter them to throw out any solids. This is where sintered plastic filters come in. They can easily filter out solid particles found in industrial liquids, ensuring that only the liquid gets discarded, while the solid waste is collected and disposed of.

Deep axial backwash filtration

A sintered plastic filter is used in deep axial backwash filtration systems like the three-micron filter. Its design permits effective filtration of water as well as simultaneous backwashing for cleaning. This gives consistent water clarity and maintains filter performance.

Biomedical applications

In the biomedical field, sterility is of utmost importance. Sintered plastic filters are used to keep patients safe by allowing only air to pass through while trapping bacteria and other pathogens.

Process air filtration

In process air filtration, sintered filters help get rid of the gases and keep production lines working well. They get rid of contaminants like dust, metal shavings, and other tiny particles. Even while letting the clean air and the gases pass, they remain sturdy and block pollutants effectively.

Fume extraction

In the extraction of fumes, sintered plastic filters are helpful by capturing fumes and smoke from welding or any other such operations. By capturing harmful particles, they contribute to the health and safety of workers, thus ensuring that they remain safe and protected from hazardous fumes.

Gas filtration

In the case of gas filtration, these filters work as a safeguard for engines and other machinery. They obstruct the entrance of powdered materials, dirt, and water so that machines work well without any problems. Besides, sintered plastic filters are robust and provide excellent filtration, thus making them very effective in protecting industrial equipment from damage.

Buyers should consider the following plastic filter cartridge sintered filter elements when purchasing.

Raw Material Selection

Choosing a suitable polymer material is essential for balance in strength, temperature resistance, and chemical resistance. Depending on the application requirements, the procurement can select materials like nylon, polytetrafluoroethylene (PTFE), or polypropylene.

Pore Size

The pore size determines the filtration accuracy and flow rate. Select a pore size that matches the intended application. For example, a sintered plastic filter with fine pores can achieve high filtration accuracy but may have a lower flow rate.

Filtration Area

The filtration area affects the filtering capacity and maintenance frequency. A larger filtration area can improve the service life of the filter. However, it may increase the volume and weight of the filter.

Mechanical Properties

Consider the mechanical properties of sintered plastic filters, such as compressive strength and tensile strength. These properties determine the filter's ability to withstand pressure and its durability.

Temperature and Pressure Ratings

Sintered plastic filters operate under specific temperature and pressure conditions. Ensure that the chosen filter can withstand the operating conditions to prevent deformation or damage.

Compatibility with Fluids

Sintered plastic filters are used to filter various fluids. Ensure that the chosen filter is compatible with the specific fluid to prevent chemical reactions or degradation.

Configurational Design

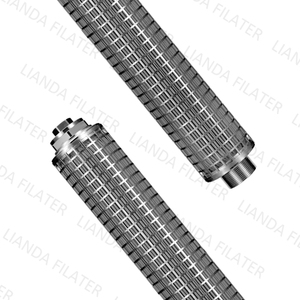

Consider the configurational design of sintered plastic filters, such as cylindrical, disc, or cartridge designs. Select a configuration that fits the installation space and requirements.

Cost and Performance

Balance costs and performance. Consider factors such as performance, quality, and service life to select filters that offer value for money.

Q1: Do sintered plastic filters have OEM/ODM service?

A1: Generally, plastic filters will have OEM/ODM services. Such services allow customers to modify or adjust products according to their preferences. Customers can communicate with the manufacturer about their specific needs, such as filter size, shape, design, and packaging, among others.

Q2: Which industries commonly use plastic sintered filters?

A2: There are various industries that use plastic sintered filters. These include the chemical industry, food and beverage industry, pharmaceutical industry, water treatment, and agricultural industry, among others.

Q3: Can plastic sintered filters withstand high temperatures?

A3: Unfortunately, not all plastic sintered filters can withstand high temperatures. This is because different plastic materials have distinct properties. Some materials can handle high temperatures, while others can't. Nonetheless, manufacturers can sinter specific plastic materials to create filters that can withstand heat.