Introduction to Silk Fabric Making Machine

The silk fabric making machine is an innovative and essential piece of equipment designed for the efficient production of high-quality silk fabrics. This technology not only streamlines the manufacturing process but also ensures that the delicate nature of silk is preserved. Silk, known for its lustrous texture and luxurious feel, has been a staple in the textile industry for centuries. As demand increases, employing a specialized machine can significantly enhance production speed and quality, making it a valuable asset for manufacturers.

Types of Silk Fabric Making Machines

- Silk Reeling Machines: These machines are used for unwinding raw silk threads from cocoons. They are designed to handle the delicate fibers without causing breakage.

- Silk Spinning Machines: Used for spinning the prepared silk threads into continuous yarn, these machines play a crucial role in the fabric production process.

- Weaving Machines: Once the yarn is ready, these machines are necessary for creating the fabric itself, interlacing threads to produce various silk patterns and textures.

- Dyeing Machines: To enhance the beauty of silk fabric, dyeing machines allow for uniform color application, ensuring the fabric retains its vibrant hues through repeated washes.

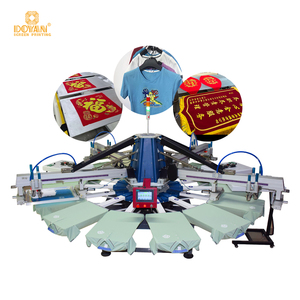

Applications of Silk Fabric Making Machines

The applications of silk fabric making machines span across various industries, making them versatile tools in fabric production. Here are some primary applications:

- Fashion Industry: Manufacturers employ these machines to produce luxurious silk garments, catering to high-end fashion brands and bespoke tailoring.

- Home Textiles: Silk fabric is increasingly used in items such as curtains, cushion covers, and bed linens, requiring machines that can handle bulk production.

- Interior Decor: The demand for silk in upholstery and decorative fabrics is rising, necessitating machines capable of creating intricate designs and patterns.

- Gifting and Accessories: Silk scarves, ties, and handbags benefit from specialized machines that produce fine silk with exceptional craftsmanship.

Features and Advantages of Silk Fabric Making Machines

Investing in a silk fabric making machine comes with numerous advantages, ensuring that manufacturers meet quality standards while enhancing productivity. Key features include:

- Automated Processes: Many machines come equipped with automated features that reduce labor costs and increase efficiency.

- Precision Control: Advanced technology allows for precise control over tension and speed, ensuring consistent quality in silk production.

- Versatility: Machines can often handle various silk types and weights, making them versatile for different products.

- Energy Efficiency: Modern machines are designed to be energy efficient, reducing operational costs and environmental impact.

The incorporation of silk fabric making machines into production lines can also lead to higher profit margins due to improved quality and decreased manufacturing times. With the growing demand for silk products globally, these machines can provide a significant competitive edge in the textile industry.