All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(6933 products available)

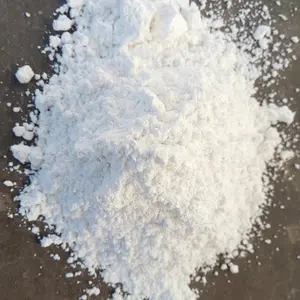

There exist various types of silicon dioxide powders. The differences are majorly based on the source, purity, particle size and amorphous/crystalline structure. Here is a quick overview:

Amorphous Silicon Dioxide

Amorphous silicon dioxide is not crystalline as it has no defined structure. Rather, it is found in an irregular arrangement of atoms. Normally, this type is produced from silica gel, diatomaceous earth and precipitated silica. Due to its non-crystalline structure, amorphous silicon dioxide has better adsorption and thickening properties compared to its crystalline counterpart. Thus, it finds many applications in cosmetics, food products and pharmaceuticals.

Crystalline Silicon Dioxide

This is the most common type of silicon dioxide. Often, quartz, cristobalite and triphANE are the main forms of crystalline silicon. This form is highly stable and has a defined geometric structure. Though, it is less reactive than the amorphous form. One of the key applications of crystalline silicon dioxide is in the manufacturing of glass, ceramics and electronics.

Precipitated Silica

This type of silicon dioxide powder is manufactured by precipitation from sodium silicate solution. The silicon dioxide is then purified using acid. As a result, this process leads to silica with very high purity. Sometimes, the silica particles are treated using heat to improve their absorptive surface area. Often, precipitated silica is used for its anti-caking properties in the food and pharmaceutical industries.

Diatomaceous Earth

Diatomaceous earth is derived from fossilized remains of diatoms. These are tiny aquatic organisms that naturally produce silica. If always unrefined, diatomaceous earth contains other minerals in addition to silica. These may include magnesium or iron. However, silicon dioxide can be extracted from high-quality diatomaceous earth. Normally, this powder is used in filtration, agriculture, and even as a natural insecticide.

Fumed Silica

Fumed silica is derived from the flame hydrolysis of silicon tetrachloride. Normally, it results in microscopic silica particles with extremely high surface area and unique properties. Because of that, fumed silica is often added to polymers to improve mechanical properties. Also, it is added to paints in order to enhance their durability.

Silica Gel

Silica gel is an amorphous form of silicon dioxide that is in a porous, granular form. Often, it is synthesized from sodium silicate through the process of acidification and precipitation. Silica gel is famous for its moisture-absorbing properties. Normally, it is used in desiccants, drying agents and inthe preservation of leather products, food and electronics.

There are many industrial usages of silicon dioxide powder. Below is a list with exposition:

Glass and Ceramics

Silicon dioxide is a key ingredient in soda-lime glass production. This includes all glass types, including bottles, windows and even fiber optics. Usually, the silica sand used in glassmaking has a high purity level to avoid impurities inclusion, which would affect the glass quality. Besides, in ceramics, silicon dioxide contributes to the vitrification process during firing. This leads to a better glassy phase that improves the strength and durability of ceramic products.

Steel and Metal Manufacturing

In the metal industry, silicon dioxide is majorly utilized in the production of flux in the furnaces. Normally, it aids in the removal of impurities from the ores during the smelting process. Also, in the production of silicon alloys used in stainless steel manufacturing, silicon dioxide serves as a key source of silicon.

Chemical Industry

Silicon is crucial in producing silicones, which are versatile polymers used in lubricants, sealants and adhesives. Commonly, silicon dioxide is utilized as a filler in synthetic rubber manufacture. This improves the tire's strength and durability for vehicles. Also, silicon dioxide can be found in pesticides for agricultural uses. Here, it improves efficacy when dry powders are sprayed.

Electronics

Silicon dioxide, due to its insulating properties, is highly employed in electronics. Usually, it functions as a dielectric layer in capacitors and other electronic components. In semiconductor manufacturing, silicon dioxide layers are deposited on silicon wafers. This is to serve as an insulator or as part of the gate in field-effect transistors (FETs). Additionally, silicon dioxide is used to produce fiber optic cables for the telecommunications industry.

Construction

This powder is a key component in the cement production process which is critical for the construction industry. Often, it reacts with other oxides to form silicate compounds that contribute to the strength of concrete over time. Additionally, silicon dioxide is found in aggregates used in concrete and asphalt for roads and buildings.

Food Industry

Silicon dioxide powder is commonly used as an anti-caking agent in many food products and even supplements. Normally, it helps in maintaining granular additives like salt and sugar. This prevents clumping. Also, it aids in improving the fluidity and uniformity of powders within seasonings and dietary supplements.

Silicon dioxide powder has numerous advantages. They cut across different industries and fields. Below is a list of the common ones:

Improved Product Quality and Performance

This powder enhances the performance of many products in the cosmetic and food industry. Normally, it acts as an anti-caking agent. This helps in preventing clumping in powdered supplements and foods. Therefore, ensuring smooth product application and consumption. Also, fumed silica used in rubber strengthens tires. This improves the products’ mechanical properties and extending their lifespan.

Versatility and Broad Applicability

Silicon dioxide is really a highly adaptable compound with a wide range of applications. These include industrial, agricultural, food and pharmaceutical uses. It is commonly utilized in filtration, desiccants, and as a carrier for agricultural pesticides and vitamins. The powder caters to diverse needs across different markets. These markets include glass production, electronics and construction sectors.

Safety and Tolerance

Silicon dioxide is a naturally occurring compound. This makes it safe and well tolerated in different applications within the food and pharmaceutical industries. It is used as an additive and anticaking agent. Normally, it aids in improving the product quality without posing risks to consumer health.

Cost-Effectiveness

This powder can boost production efficiency using relatively low costs. In the rubber industry, for example, silica reinforces tires. This leads to reduced long-term costs to manufacturers because of the increased durability. Also, in glassmaking, it is readily available and thus contributes to inexpensive production processes.

Environmental Considerations

This powder occurs naturally and is abundantly mined. Silica is extracted from diatomaceous earth, or even quartz. Then it is processed into different forms, such as fumed or precipitated silica, which are engineered for specific uses. Therefore, it presents a sustainable option compared to synthetic materials that require more energy-intensive processes to produce.

A buyer should consider several factors when purchasing silicon dioxide powder. Below is a list of these factors:

Purity and Quality

Buyers should look for high-purity silicon dioxide. Ideally, this should be at least 99% to 99.5%. Also, it should not contain any contaminants like metals or other minerals. Purity is vital when it comes to food, pharmaceuticals and electronics manufacturing. In these industries, even the slightest impurity can have detrimental effects on product quality and safety. To ensure quality, buyers should settle for silicon dioxide from reputable suppliers. Normally, they have good market ratings.

Type of Silica

Silicon dioxide powder exists in several types. They include amorphous silica, fumed silica, precipitated silica and diatomaceous earth. Each type has its unique properties that fit certain applications. For example, fumed silica has a very high surface area. While precipitated silica has been widely used in food and pharmaceuticals. Buyers should research each silica type to identify which one suits their clients' needs.

Particle Size and Distribution

The particle size of silicon dioxide can significantly influence its application. For instance, in the rubber industry, silicone compounds require specific particle sizes for reinforcement. Also, in the pharmaceutical industry, the bioavailability of drug compounds largely hinges on the particle size. Therefore, buyers should ensure that the powder sold to them has the right particle size for the intended usage.

Usage and Application

Usually, silicon dioxide powder has a variety of uses in different industries. These industries include food, pharmaceuticals, agriculture, construction and rubber. Buyers should ensure the silicon dioxide powder they purchase for resale has the right applications for their customers. For instance, precipitated silica works extremely well as an anti-caking agent in the food and supplement industries. On the other hand, fumed silica is often used as a reinforcing agent in rubber compounds for the automotive and tire industries.

Industrial Standards and Certifications

Buyers should check whether the silicon dioxide powder meets necessary regulatory standards and certifications. Mostly, these certifications include FDA approvals, REACH compliance and USP standards. These certifications are critical for silica applications in the food, pharmaceutical and cosmetics industries. Moreover, they help in ensuring product safety and quality.

Yes, silicon dioxide is widely used in organic farming. Normally, it's a key component of diatomaceous earth. Farmers use diatomaceous earth to control pests naturally without harming beneficial insects. Apart from that, silicon dioxide enhances soil structure, increases water retention, and promotes healthy plant growth. This consequently leads to improved crop yields and quality in a natural way.

Silicon dioxide is normally safe for daily intake when it is included as a dietary supplement. Often, it acts as a flowing agent. Thus, it helps in the even distribution of powdered nutrients and vitamins. Besides, it promotes healthy bones, skin, hair and nails. The supplement usually comes in encapsulated or tablet forms. This makes it convenient to integrate this element into daily routines.

No. Actually, adding silicon dioxide to tires has great benefits. Usually, it enhances fuel efficiency, tread wear and traction. These benefits improve the overall performance of an automobile tire. Also, tires using this compound promote better handling and stability. Therefore, tires lasting longer with reduced environmental impact are produced.

Regular inhalation of silicon dioxide powder can have serious long-term health consequences. For example, it causes silicosis, a lung condition characterized by scarring of lung tissue. In the short term, prolonged exposure may cause chronic bronchitis and increase the risk of respiratory infections. In some cases, inhaling this powder may eventually increase the risks of lung cancer and other pulmonary diseases. They include pulmonary fibrosis.

Silicon dioxide powder is widely employed in cosmetics and skincare products. Normally, it acts as an anti-caking agent and absorbent. Therefore, it contributes to smoother applications and helps control oil on the skin. Also, due to its exfoliating properties, it can aid in removing dead skin cells. This leaves the skin fresh and revitalized.