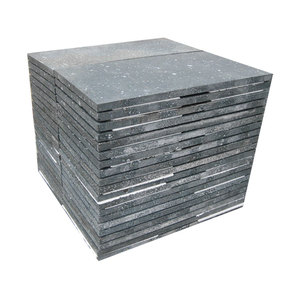

Introduction to Silicon Carbide Carborundum Brick

The silicon carbide carborundum brick is a high-performance refractory material widely recognized for its superior thermal and mechanical properties. Engineered to withstand extreme temperatures, it serves as an essential component in various industrial applications, including metal processing, chemical production, and ceramics manufacturing. Thanks to its exceptional characteristics, this brick is increasingly adopted in environments requiring both durability and thermal resistance.

Types of Silicon Carbide Carborundum Brick

Silicon carbide carborundum bricks come in several types, each designed for specific temperatures and applications:

- Ordinary Silicon Carbide Brick: Typically used in regular industrial environments, offering decent thermal shock resistance.

- High-Purity Silicon Carbide Brick: Contains higher purity levels of silicon carbide, making it ideal for high-temperature applications where contamination is a concern.

- Silicon Carbide Composite Brick: A hybrid material often combining silicon carbide with other refractories to enhance mechanical strength and thermal stability.

- Layered Silicon Carbide Brick: Featuring a unique layered structure for optimized thermal and mechanical performance in challenging conditions.

Features of Silicon Carbide Carborundum Brick

The silicon carbide carborundum brick is known for its remarkable features:

- High Thermal Conductivity: Silicon carbide bricks efficiently transfer heat, making them perfect for furnaces and kilns.

- Outstanding Wear Resistance: These bricks demonstrate excellent durability, extending their lifespan even in abrasive environments.

- Low Thermal Expansion: They exhibit minimal expansion under thermal stress, maintaining structural integrity in fluctuating heat conditions.

- Corrosion Resistance: Capable of resisting chemical reactions, particularly useful in environments exposed to molten metals and slag.

Applications of Silicon Carbide Carborundum Brick

The versatility of silicon carbide carborundum brick enables its use across various industries:

- Metallurgical Industry: Used in electric arc furnaces and ladle linings for steelmaking.

- Ceramics Manufacturing: Applied in kilns where high-temperature resistance is crucial for product quality.

- Chemical Processing: Utilized in reactors and heat exchangers to maintain operational efficiency and reduce wear.

- Aerospace Applications: Ideal for components exposed to extreme conditions, contributing to the longevity and safety of aerospace parts.