(685 products available)

SF6 leak detector is an instrumental device in various domains, especially where monitoring of gas integrity is crucial. Functioning primarily on sensitivity to sulfur hexafluoride (SF6), a potent greenhouse gas, these detectors come in versatile types to cater to specific needs and environments. Below is a detailed classification based on operating principle, measurement mode, and application.

Portable detectors in this category are designed for mobility. This feature enables users to perform on-site gas monitoring without being restricted by power sources or infrastructure. These devices are extensively used in fieldwork to guarantee real-time leak detection in large facilities or outdoor installations. Their lightweight bodies, battery operation, and rugged design contribute significantly to their widespread use in industries requiring constant SF6 surveillance across various working conditions.

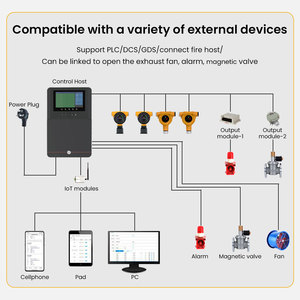

Devices for continuous monitoring have been developed for environments where constant SF6 presence is vital. These systems are installed in fixed locations to provide real-time data, enabling immediate reaction to any detected leaks. With advanced sensitivity and data logging features, they are critical in spaces like gas-insulated substations. The ability to detect leaks instantly and emit alerts allows companies to take preventive measures quickly and thus minimizes both operational hazards and long-term environmental risks.

Infrared detectors offer a non-contact measurement method by sensing SF6 gas through infrared technology. This method ensures high accuracy without direct exposure to the gas, making it suitable for environments where safety is a top priority. The technology provides an extensive measurement range and is unaffected by other gases, giving it accuracy and reliability in detecting SF6 leaks. Its non-invasive approach applies to industries looking for precise data without compromising safety or equipment quality.

Ultra-sensitive detectors enhance detection capability, identifying trace amounts of SF6. The ultra-sensitive SF6 gas analyzers are instrumental in highly sensitive areas such as laboratories or high-voltage installations, where minor leaks can result in severe consequences. These devices incorporate advanced technologies, such as mass spectrometry or highly sensitive sensors, to achieve minimum concentration levels. Their capability to detect negligible leak rates significantly reduces the environmental impact and improves the reliability of operations.

Durability is a critical factor for SF6 leak detectors, as they must operate effectively in multiple settings, from high-voltage substations to outdoor industrial zones. Understanding the materials and durability features of these devices not only guarantees their longevity but also improves their performance under changing environmental conditions.

The housing or casing of an SF6 leak detector is made of strong materials such as polycarbonate, ABS plastic, or aluminum alloys. These materials protect the internal components from water, dust, and physical impacts. Polycarbonate enclosures are most commonly used due to their excellent balance between toughness and impact resistance. Detectors exposed to harsh outdoor conditions will often feature weatherproof casings for protection from moisture and extreme temperatures.

Given that the SF6 leak detectors may operate in extreme temperatures or chemical environments, the internal and external components must resist this volatility. High-grade seals and O-rings, commonly made from Viton or Nitrile, ensure that the internal mechanisms are protected from gas infiltration and degradation. The materials in these detectors are also resistant to common industrial chemicals. These include oils, solvents, or acidic compounds that the device may come into contact with in industrial settings.

Beyond the housing, internal components, such as sensors and circuit boards, must be durable enough to withstand continuous operation. Sensors are typically made from materials like ceramic or silicon semiconductors. These materials are extremely sensitive and can detect very small concentrations of SF6. However, they need to be robust to avoid physical damage or thermal wear. Component durability is also important to prevent premature sensor failure in devices exposed to high concentrations of SF6 or extreme environmental factors.

For portable SF6 detectors, battery life and sealing technology are important for extended usage. Long-life lithium-ion batteries are commonly used, allowing longer periods of operation without the need for recharging. Advanced sealing technologies, such as mechanical seals or laser-welded joints, ensure that the device is airtight and can sustain internal pressure, thus maintaining accuracy. These features make the device efficient and reduce the need for frequent maintenance or replacement.

The use of sulfur hexafluoride leak detectors extends to many industries, ensuring safety, operational efficiency, and environmental stewardship. Several key scenarios underline the versatile application of these detectors, emphasizing their crucial role in effective leak management.

Leak detectors monitor SF6 equipment in this industry, especially in substations and gas-insulated switchgear. Sulfur hexafluoride test equipment identifies leaks promptly to prevent safety hazards and safeguard expensive electrical infrastructure. Real-time leak detection capabilities protect critical equipment, lower operational costs associated with gas refills, and guarantee compliance with environmental regulations.

In chemical plants where SF6 is utilized or produced, leak detectors are crucial for maintaining safety levels. Early SF6 detection helps mitigate explosion risks and other harmful chemical interactions, protecting personnel and reducing downtime. Deploying detectors allows continuous monitoring that enhances productivity by facilitating immediate leak management and thus avoiding expensive operational interruptions.

High-precision research facilities, including semiconductor and medical research labs, need an ultra-sensitive leak detector to ensure pristine work environments. In these settings, even minor SF6 leaks can significantly impact sensitive experiments or equipment, leading to inaccurate results or damage. Identifying leaks quickly protects research integrity, reduces operational costs, and avoids delays. This efficiency ensures projects stay on track, improving overall work productivity and long-term project feasibility.

SF6 leak detectors are invaluable tools for specialists providing inspection and maintenance services to multiple industries. These devices allow inspectors to quickly locate leaks in various installations, from pipelines to high-voltage equipment. The ability to conduct thorough leak assessments with portable detectors increases inspection efficiency and reduces the risk of undetected leaks. This thoroughness leads to lower repair costs, minimizes downtime from leak-related issues, and ultimately enhances system longevity, giving companies reliability and saving costs.

The variety of options and the growing importance of accurate leak detection in multiple industries make selecting the right SF6 leak detector critical. To choose a suitable device, several factors must be considered to meet specific operational needs and maintain efficiency while staying on budget.

This parameter mainly determines the device's ability to identify small SF6 concentrations, thus impacting operational safety and reliability. In highly sensitive environments such as power stations or research labs, ultra-sensitive detectors may be required, which can pinpoint minute leaks accurately. Therefore, a detector with high measurement accuracy will likely ensure compliance with environmental regulations, avoid leak-related risks, and reduce gas emissions. Always select a detector that meets the requirement for its operational environment.

Portability is essential for fieldwork as mobility allows leak detection across multiple sites without being tethered to a power supply. Fixed detectors are better suited for continuous monitoring in stationary environments. The choice between portable and fixed depends on the leak detection needs and working conditions.

The user-friendliness of an SF6 leak detector can significantly impact operational efficiency. This is because intuitive interfaces and simple controls reduce the time required for training and operation. Additionally, considering maintenance requirements, such as calibration and part replacements, helps ensure long-term reliability without causing significant downtime. Always select one that will not require much time to maintain and operate.

Complying with local environmental regulations directly influences the selection of an SF6 leak detector. Some jurisdictions have stringent rules regarding greenhouse gas emissions, requiring instruments that detect and report SF6 leaks. Therefore, choosing a detector that aligns with these regulatory requirements will minimize legal risks and ensure compliance. Detectors with built-in reporting capabilities may help meet regulatory documentation requirements.

Cost is always an important factor when choosing an SF6 leak detector. Initial acquisition costs of various instruments might differ considerably; however, long-term factors should always be taken into consideration. Fixed detectors are usually installed once and do not require continuous labor for monitoring, making them cost-effective in the long term for static environments. In contrast, portable detectors are more labor-intensive. Cost factors include maintenance, sensor replacements, and operational lifespan. Balancing initial and ongoing costs ensures that the chosen device fits within the budget without compromising required accuracy and reliability.

A1: It is used for monitoring sulfur hexafluoride gas in various industrial settings to ensure equipment safety, improve operational efficiency, and enhance environmental compliance to avoid expensive leaks.

A2: Sensitivity is crucial as it determines the detector's ability to identify small SF6 concentrations, thus impacting early detection, preventing safety hazards, and ensuring environmental compliance.

A3: Yes, several detectors, such as infrared leak detectors, are designed for continuous monitoring, providing real-time data and ensuring immediate leak detection for early intervention.

A4: Long-term costs depend on the maintenance required, with fixed detectors having lower ongoing costs than portable ones, making them more cost-effective for long-term operations.

A5: The detectors comply with environmental regulations regarding gas emissions and typically have built-in reporting features to facilitate adherence to regulatory documentation requirements.