Understanding Servo Spindle

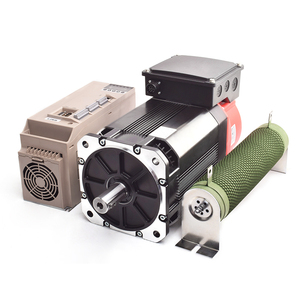

A servo spindle is an innovative piece of machinery designed for high-precision applications in various industries. Combining advanced servo motor technology with a spindle, this tool provides exceptional control and speed, making it an essential asset in modern manufacturing processes. By using a servo spindle, businesses can benefit from improved performance, reduced cycle times, and enhanced product quality.

Types of Servo Spindles

- AC Servo Spindles: These spindles utilize alternating current to provide consistent torque and speed, making them ideal for high-performance applications.

- DC Servo Spindles: Operating on direct current, these spindles offer simplicity and reliability, suitable for applications where precision is paramount.

- Integrated Servo Spindles: These models combine the motor and spindle into one unit, optimizing space and reducing assembly time.

- High-Speed Servo Spindles: Designed for applications requiring rapid rotation, these spindles operate at high RPMs, ideal for machining intricate designs.

Applications of Servo Spindle

Servo spindles are ubiquitous in various sectors due to their versatility and efficiency. Their applications include:

- CNC Machining: Servo spindles are widely used in CNC machines for milling, drilling, and turning operations, providing accuracy and repeatability.

- Manufacturing Automation: These spindles are integral to automated assembly lines, facilitating fast and precise manufacturing processes.

- 3D Printing: In advanced 3D printing technologies, servo spindles enhance precession and speed, allowing for detailed and complex structures.

- Robotics: Used in robotic arms, servo spindles aid in precision movements, promoting efficiency in tasks like packaging and assembly.

Features and Advantages of Servo Spindles

Choosing a servo spindle comes with numerous benefits that elevate manufacturing standards:

- Precision Control: Servo spindles offer superior positional accuracy and repeatability, crucial for high-quality production.

- High Torque Density: They provide exceptional torque output at varying speeds, allowing for flexible operation across different applications.

- Energy Efficiency: Servo technology optimizes energy consumption, leading to cost reductions and improved environmental sustainability.

- Low Maintenance: With fewer mechanical components, servo spindles tend to require less maintenance and exhibit greater durability compared to traditional spindles.

- Enhanced Cooling Systems: Many servo spindles feature advanced cooling mechanisms that prevent overheating, ensuring consistent performance during extended operations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4