All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2495 products available)

Screen printing machines for auto glass come in several types, each suitable for the required production volume and operational complexity. Here is a rundown on the main types.

These are the most simple solution, as they require an operator to manually press the screen to squeegee the paste. They provide flexibility and are good for small batches or exclusive individual needs.

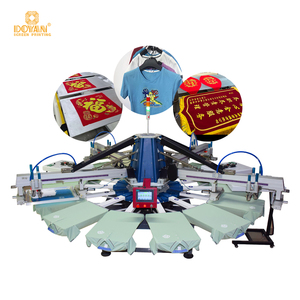

In these, the whole process is automated, allowing for more printing with less labor. Uniformity is greater with these, and they're ideal for sizable production runs where printing density must remain constant.

These machines strike a balance between manual and fully automatic systems. While they still require some manual intervention, aspects such as squeegee motion and screen overlap are automated. These machines are suitable for medium production volumes and offer a good compromise between cost and efficiency.

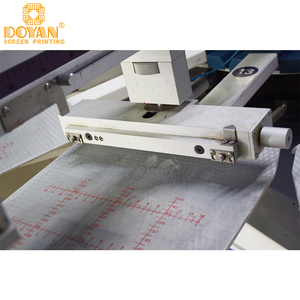

These machines are used when the glass surface is flat and the printing design is more geometrically straightforward. They allow a uniform distribution of the ink on flat areas.

These are specialized for cylindrical or curved surfaces and provide consistent ink application across the shape. These suit auto glass with rounded sides or complex curves more effectively than flat screen printing machines.

Each machine that uses pressure to put color on auto glass has some different parts or features. Knowing them can help one understand why some machines work better than others. Here are the prominent features of these machines.

This defines how many screens can be pushed through the machines in a day. Big machines can do more work quickly and are better for large projects. Smaller ones are for simpler, smaller jobs.

The clearer the final picture is, the better the print quality. This screen printing machine makes sure the colors and lines on the glass look sharp. This matters a lot, especially when using different colors.

Some machines can use different kinds of ink, like the one for glass. Others only compatible with a few inks. The right ink makes the design last longer. It's important to ensure that it is the right kind of ink for auto glass.

How big a machine is and how it looks play a part, too. Such machines come in different shapes and sizes. One must choose one based on how much space one has and how many jobs one usually has.

Some of these machines move all on their own. A few still need some help from people to run. The machines that do everything by themselves help to finish jobs faster. It is more about how many screens or layers of color are needed for a single job.

A few of these machines are easy to use, and changing things when printing is being done is simple. This makes it faster to switch tasks. But, tougher machines often take more time to set up, but they can work better in the long run.

Forbes Commercial printing machines are important in many settings as they help in different tasks. Here are some of these machines' popular uses in business environments.

These machines are good for making large numbers at once. If many car windows need the same print, it is quick and easy through these machines. They make lots of printed glass fast and keep quality the same.

Cars have many small printed parts. These machines help print labels on auto glass for special orders. This means the glass can be made to fit specific designs or unique cars quickly and easily without any issues.

Printed glass often has safety designs, like prints that stop shattering. These machines print lines or marks on glass that make it safer to use. The faster this is done, the more secure the glass becomes for use.

Billions of printed auto glass have car company symbols or designs on them. These machines help cars put prints, like logos, on windows and other glass parts, making each print look sharp and smooth. They work better for big orders of glass with the same design.

For special cars with unique prints, these machines can switch from making many prints to making one special print. They allow businesses to work on both kinds of glass, special and standard, all in one place.

Windows can be printed with special coatings or tints after a car is made. These machines apply prints to windows for various aftermarket upgrades, like shades or protective films on glass. They apply these prints quickly, giving the car extra value.

Many choices are available, and it's not easy to pick the right one. But it helps to know what matters most. Here are some important factors to consider when choosing screen printing machines for auto glass.

Consider whether only a few colors are needed or many at once. Some machines manage easier jobs, while others are set up for complex prints. Complex jobs require machines with more setup options and flexibility to handle intricate tasks.

Make sure to choose a sturdy machine that will last for a long time and withstand the heat and stress from printing on glass materials and screens. Tough machines are better for big jobs that need constant work.

If a lot of material needs to be printed at once, it is best to use a robust machine that can easily handle such tasks without breaking down. Machines that manage larger tasks typically last longer and function better in high-demand spaces.

It is essential to choose a printer that can make designs as sharp and detailed as possible. Machines capable of high-resolution printing will produce cleaner lines and smoother images. This ability significantly impacts overall print quality.

The number of steps needed to start the printing process can take a long time. One should choose a machine that needs less work to set up for the first print. This factor is especially important if there are frequent changes in projects.

It is also important to ensure that any pattern or design is perfectly placed, especially for double-color jobs. Misalignment can create messy prints. Machines that have strong alignment systems reduce this risk, improving print quality.

Special ink for glass is the best option. Normally, it is polyester-based ink made for smooth and non-porous materials like glass. This type of ink sticks well to the surface and dries to a hard, durable finish. It also uses less energy to apply the ink.

Yes, there is a safety factor involved in using screen-printed auto glass. The inks used in prints are heat-treated to ensure they bind tightly to the glass surface. Tempering plastic layers inside the glass also strengthen it and secure the prints in place during use.

Although both methods are used to make images on various surfaces, they differ in their processes. Learning the exact processes can help one choose the correct method. Screen printing uses a mesh screen to push ink onto a surface, while digital printing uses a printer to transfer ink directly onto a surface.

Yes, many such printed auto glasses have coatings that can block UV rays. The UV-blocking material is printed onto the glass or laminated between glass layers during processing. This helps to protect car interior parts and skin from harmful rays.

Aftermarket printing on auto glass mainly involves applying prints after the glass is manufactured. A common process is using screen printing to add custom designs or patterns. This allows for unique appearances or additional features like solar control.