(170 products available)

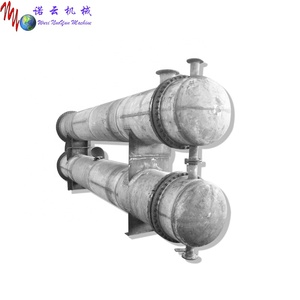

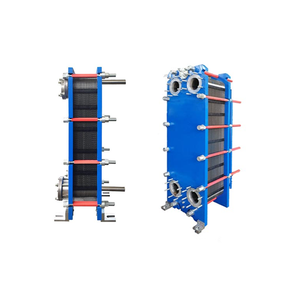

Scraped surface heat exchangers are industrial machines used to transfer heat between two fluids. They are engineered such that one fluid takes in, or loses heat, while the other does the contrary. The design of a scraped surface exchanger allows the continuous movement of fluids, hence the ability to perform heat exchange at a constant, continuous rate. Most heat exchangers are designed with a scraping mechanism that keeps the surface free of any deposits.

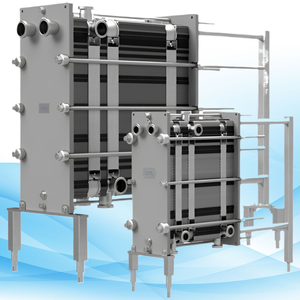

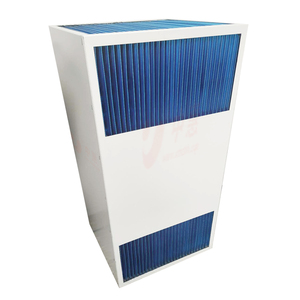

Heat exchangers are typically categorized based on their flow arrangement and design. Mechanisms such as counterflow, co-current, and mixed flow arrangements are popular when describing a heat exchanger.

An industrial-grade scraped surface heat exchanger will have an abrasive scraper that shaves off material from the surface. The scraper may be made from stainless steel or any other durable material. The machine is also fitted with a drive motor that controls the speed at which the scraper moves.

Applications

Surfaces that have scraping abilities are preferred when products need to be continuously scraped, e.g., in the dairy, food, and chemical industries. Powder, granules, and dairy products like milk, cheese, and ice cream are common examples that may run through a scraped heat exchanger.

Some specifications of the scraped heat surface exchanger are as follows:

In addition, the scraper surfaces of the scraped surface heat exchanger also have to be replaced regularly and checked to discover any damage, excessive wear, or leaks of the scraper type surface exchanger parts. Then, repair or change them in time. Also, adding lubricating oil to the sliding bearings of the driving system of scraped surfaces can keep the driving system operating fluently and steadily. Additionally, operators should train their staff and ensure proper operation and use of the scraped surface heat exchanger according to the manufacturer's instructions, preventing early breakdowns or faults caused by improper operation.

Some industries that rely heavily on scraped surface exchangers include food and beverage, dairy, chemical, and pharmaceutical processing.

Food processing industry

Surfaces are heated by scrapers while cooking food. Modified exchangers that aren't scraped can be used to cook solid foods that don't dissolve in liquid. Ice cream makers use heat exchangers to cool and set mixtures before freezing. Because the temperature must be lower than the freezing point to achieve that, the use of scraped surface heat exchanger (SSHE) is very important in the industry.

Dairy industry

In the dairy industry industries, SSHEs are used for a variety of applications. Milk, for example, must be pasteurized before it is released into the market, which is essentially killing bacteria. The process must be done quickly, so SSHEs come in handy. They are also used to homogenize milk, improve its consistency and prevent it from separating.

Chemical processing

In the chemical processing industry, SSHEs are used to carry out chemical reactions. Exchangers help control chemical reactions by quickly cooling or heating chemicals. They also assist in the crystallization of chemicals by cooling a hot chemical mixture. Chemicals that crystallize are filtered and dried.

Pharmaceutical industry

In the pharmaceutical industry, SSHEs are used to quickly cool or heat liquids, slurries, and solutions. Drugs must be produced quickly in order to combat disease. The exchanger also assists in condensation and evaporation processes to separate, purify, filter, and dry essential compounds.

Petrochemical industry

In the petrochemical industry, scraped-surface exchangers are used to solidify and crystallize paraffin. If paraffin is not solidified promptly, it will clog pipes and be difficult to handle.

When choosing a scraped surface heat exchanger, several factors need to be considered to ensure that the suitable equipment is selected for a specific application.

Product Properties:

Determine the type of food (liquid, slurry, paste, or solid) that the surface scraper heat exchanger will handle. Identify any special requirements, such as corrosive or abrasive food components, that may necessitate durable materials or specific design features.

Thermal Requirements:

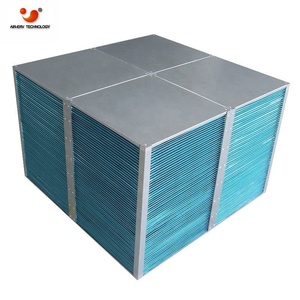

Consider the thermal demands of the food processing application. Evaluate the required heat transfer rate, the temperature change (heating, cooling, or both), and the desired temperature variation. Based on these factors, determine the appropriate exchanger size and capacity.

Scraping Mechanism:

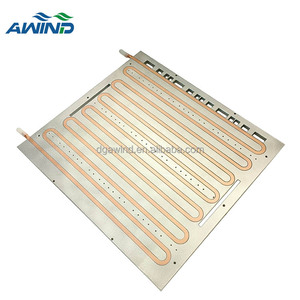

Choose the design of the scraping mechanism (e.g., blade, pat, or plate) based on its effectiveness, maintenance requirements, and compatibility with the processed food material. Consider the number, arrangement, and frequency of scraper operation.

Construction Materials:

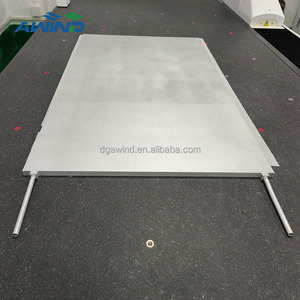

Select suitable materials for the exchanger's construction, including the shell, tubes, and scrapers. Ensure that the chosen materials meet food safety standards, are easy to clean and maintain, and can withstand the application-specific operating conditions (temperature, pressure, and corrosion).

Operating Parameters:

Determine the exchanger's operating parameters, including the temperature and pressure of the heating/cooling medium, the flow rates of the food material and the heat transfer medium, and the exchanger's overall heat transfer coefficient. These parameters will influence the exchange's efficiency and performance.

Cleaning and Maintenance:

Consider the cleaning and maintenance requirements of the scraped surface exchanger. Choose an exchanger design that provides easy access for cleaning, adequate drainage facilities, and efficient cleaning procedures to ensure hygiene and equipment longevity.

Energy Efficiency:

Focus on the energy efficiency of the scraped surface heat exchanger. Look for models designed to minimize energy consumption, reduce heat losses, and optimize heat recovery to lower operating costs and environmental impact.

Q1: What is the principle of a scraping surface heat exchanger?

A1: Scraped surface heat exchangers work by continuously scraping the heating surface to remove the heated product that tends to get stuck on the heating surface.

Q2: Why are scraped surface heat exchangers important?

A2: SSHE are critical because they can effectively process viscous fluids, demonstrating steady temperature control, which is crucial for maintaining product quality in many applications.

Q3: What are the two main types of scraped surface exchangers?

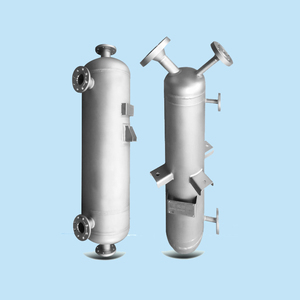

A3: The two main types of scraped exchangers are cylindrical scraped surface heat exchanger and semicircular/half-cylinder scraped surface heat exchanger.

Q4: Do all heat exchangers need to be scraped?

A4: Not all heat exchangers require scraping surfaces. Some designs allow for the natural flow of fluid to prevent the buildup of materials.