(586 products available)

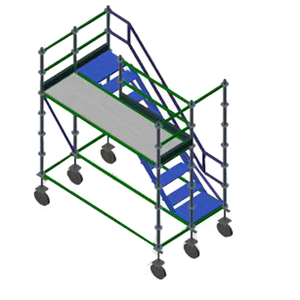

A scaffolding wheel with a lock is a wheel that helps support a temporary structure. It is used by construction workers to elevate and support individuals or materials for projects. The wheel helps move the scaffolding structure quickly from one location to another. Scaffolding wheels are also known as scaffolding casters or scaffolding wheels.

Scaffolding wheels are available in different types based on their material, load capacity, wheel diameter, and specific application. Here are the various types of scaffolding wheels:

Cast Iron Scaffolding Wheels:

These wheels are made of cast iron, which makes them robust and wear-resistant. Cast iron wheels can withstand harsh weather conditions. The wheels also offer a high load-bearing capacity, which ensures stability. Despite being durable, the wheels are susceptible to impacts. They may get damaged from strong impacts.

Polyurethane Scaffolding Wheels:

This wheel is made from polyurethane material. It is durable and provides excellent grip and traction. The wheel moves smoothly, making it suitable for both indoor and outdoor surfaces. It also has resistance to cuts and chemicals. The wheel absorbs shocks and vibrations, which ensures stability.

Rubber Scaffolding Wheels:

Rubber scaffolding wheels are made of high-quality rubber. The wheels provide excellent floor protection. They are non-marking and non-scratching. Rubber wheels are also quiet when in motion. They move smoothly without making loud noise. The wheels offer great maneuverability on various surfaces.

Braked Caster Wheels:

The braked caster wheels come with locking mechanisms, which include foot levers or hand-operated brakes. The locking mechanisms allow users to lock the wheel in place when the scaffolding is in use. The locked wheels provide stability and prevent unwanted movement.

Swivel Caster Wheels:

The swivel caster wheels come with ball bearings. The bearings are placed in the swivel raceways. The wheel can rotate 360 degrees. They are ideal for moving scaffolding through corners and tight spaces.

Heavy-Duty Scaffolding Wheels:

These wheels are designed for carrying extremely heavy loads. They are made of robust materials like steel or cast iron. The wheels provide high load capacity. They are also equipped with strong bearings and locking mechanisms.

Scaffolding casters provide mobility to the scaffolding system, allowing it to move quickly across the worksite. This feature is essential in large construction sites, where materials and personnel need to be moved efficiently.

Locking the scaffolding wheels in place is crucial for safety. Once the scaffolding is in the desired position, the locks are engaged to prevent any movement. This ensures stability and security for workers and prevents accidents that could result from unintended movement.

Scaffolding wheels are usually made of durable materials like rubber or polyurethane. These materials are capable of resisting wear and tear from frequent movement across the worksite. They are also designed to withstand harsh weather conditions, which is essential for outdoor construction projects.

Many scaffolding wheels have a load-bearing capacity of up to 1,000 lbs. This high load capacity ensures that the scaffolding system can be moved easily, regardless of the number of personnel or materials it carries.

Scaffolding wheels with locks are designed to roll smoothly on various surfaces, including concrete, asphalt, and uneven terrain. This feature is important in construction sites with different surface types.

These wheels are versatile and can be used with different types of scaffolding systems, including aluminum and steel scaffolding. This versatility makes them a preferred choice for many construction companies.

Some scaffolding wheels have swivel casters that can rotate 360 degrees. This feature allows for easy maneuvering of the scaffolding in tight spaces, making it easier to move the system around the construction site.

Many scaffolding wheels are equipped with bearings that reduce friction and ensure smooth movement. This feature is essential in large construction sites, where frequent movement is required.

Scaffolding wheels with locking brakes are easy to install and remove. They usually come with a quick-release pin or lever that allows operators to lock and unlock the wheel easily.

Scaffolding wheels are usually tested and certified by industry standards to ensure durability and reliability. This ensures that construction companies can rely on these wheels for their operations.

Scaffolding wheels with locks are essential in various industries, providing stability, mobility, and safety for elevated workspaces. Here are some common applications:

Construction Sites

Construction sites frequently employ scaffolding wheels to create mobile platforms for workers. The locking mechanism ensures a secure base when using scaffolds at varying heights. Additionally, these wheels facilitate the movement of scaffolding units across the site, enhancing efficiency and reducing manual lifting hazards.

Renovation Projects

Locking scaffolding caster wheels are vital in renovation projects, especially in expansive or multi-storey buildings. They allow workers to access different areas while maintaining stability and support. The ability to lock the wheels in place is essential when performing delicate tasks, such as painting or masonry work, requiring a steady platform.

Industrial Maintenance

Scaffolding wheels are commonly used in industrial maintenance to create movable platforms for tasks such as piping inspection, electrical work, and machinery maintenance. The locking mechanism ensures the platform remains stationary when workers carry out maintenance activities. Additionally, these wheels enable the easy repositioning of the scaffold, minimizing downtime and enhancing productivity.

Warehouses and Storage Facilities

Scaffolding wheels are essential for creating mobile storage platforms in warehouses and storage facilities. The ability to lock the wheels is crucial when loading or unloading goods, ensuring the scaffold remains stable. Moreover, these wheels enable the transportation of goods to different areas within the facility, improving operational efficiency.

Event Setup

Scaffolding wheels are used to create portable platforms for setting up stages, lighting, and other event structures in concert halls and large venues. The locking mechanism ensures stability when arranging event structures. Moreover, these wheels allow the repositioning of scaffolds to accommodate different event layouts and setups.

Shipbuilding and Maritime Industry

In the maritime industry, scaffolding wheels create movable platforms for activities like hull construction, painting, and equipment installation. The locking mechanism ensures platform stability in the often-challenging marine environments. Additionally, these wheels facilitate the movement of scaffolds along the ship's length, improving workflow and minimizing manual handling risks.

Utilities and Outdoor Applications

Scaffolding wheels are used to create mobile platforms for tasks such as tree trimming, electrical line installation, and plumbing work in utility applications. The locking mechanism ensures stability on various terrains. Additionally, these wheels enable the repositioning of scaffolds across outdoor sites, improving operational efficiency and reducing manual handling risks.

When choosing a scaffolding wheel with a lock, consider the following factors:

Load capacity

Every type of scaffolding has its own specifications, which means they can only carry a certain amount of weight. Therefore, it is important to check the load capacity of the wheel to ensure it can support the weight of the scaffolding and the materials. Look for scaffolding wheels that are durable and strong enough to handle the weight load.

Material

The material used to manufacture the wheel affects its performance. Scaffolding wheels are made with different materials, each offering different benefits. For instance, polyurethane wheels are tough and durable, making them suitable for all terrains. Consider the working environment and choose a suitable material.

Wheel diameter

The wheel diameter determines the stability and mobility of the wheel. A larger wheel will move more smoothly on uneven surfaces, while smaller wheels are more suitable for flat surfaces. Consider the surfaces the scaffolding will be moved to and choose the right diameter.

Brake system

All wheels must have a reliable brake system to stop movement and prevent accidents. The brake system controls the movement of the wheel and should be easy to operate and reliable. Look for wheels with a high-quality brake system that can withstand harsh conditions.

Environmental conditions

Different environmental conditions affect the performance of the wheel. Consider the environmental conditions where the wheel will be used, such as temperature, humidity, and terrain. Some materials perform better in specific environmental conditions, like extreme temperatures or rough terrains.

Compatibility

Scaffolding wheels are not universal; therefore, ensure that the wheel is compatible with the existing scaffolding. Check the connection points and specifications to ensure a perfect fit.

Supplier reputation

It is important to buy scaffolding wheels from a reputable vendor to ensure they provide high-quality products. Read reviews and testimonials from previous clients to learn more about the vendor. A good vendor will produce durable wheels that meet the required safety standards.

Q1: What are the requirements for a lock on a scaffolding wheel?

A1: The requirements for a lock on a scaffolding wheel include the ability to prevent the movement of the scaffold in any direction. It should be easy to engage and disengage the wheel.

Q2: What are the types of scaffolding wheels?

A2: There are several types of scaffolding wheels, including cast iron wheels, rubber wheels, and polyolefin wheels. The wheel type determines the ideal working surface.

Q3: What are the standards for scaffolding wheels?

A3: The standards for scaffolding wheels include the load capacity, wheel and caster diameter, and the locking mechanism. Other specifications are the wheel material and the scaffold caster length.

Q4: What are the two types of casters?

A4: The two types of casters are rigid or standard and swivel casters. Rider or standard casters move in a straight line, while swivel casters rotate 360 degrees.

Q5: How to choose a scaffolding wheel?

A5: To choose a suitable scaffolding wheel, consider the wheel material, load capacity, wheel diameter, caster height, and working surface. Also, consider the locking mechanism and read the wheel and caster diameter standards.